Maintenance depends on manual experience, high workload for routine checks

High maintenance costs, significant losses from unexpected downtime

Numerous industrial device protocols, difficult process data collection

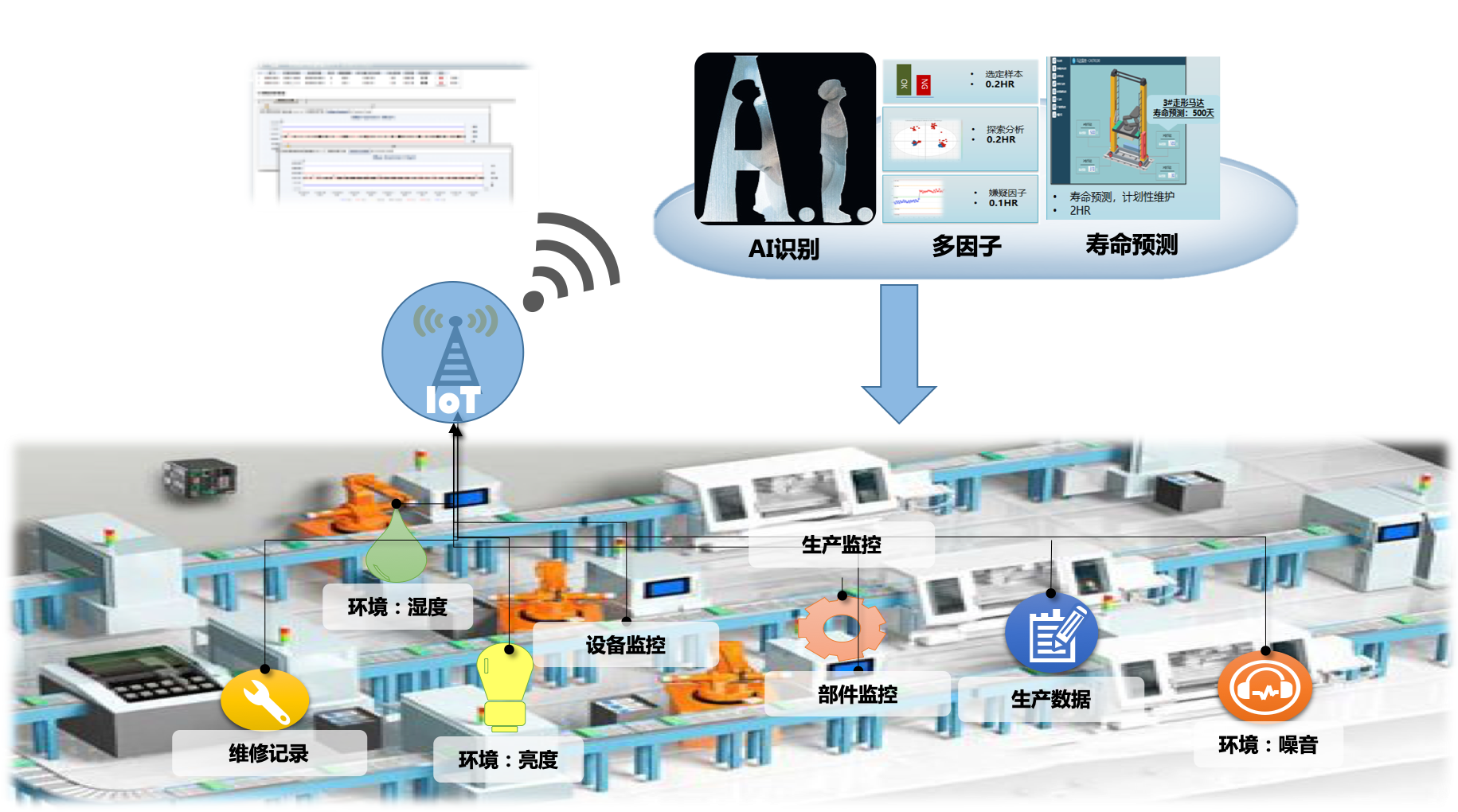

Predictive maintenance for industrial equipment targets high-value, high-energy, data-rich devices, collecting process data and adding sensors. Uses Dongzhi Platform tools for quick visualization, analysis, and optimization. Offers one-stop IoT solution for engineers with low learning curve.

Over 90% industrial field protocols

Supports millisecond-level data collection and real-time monitoring, TB-level data second-level response

For production engineers, low learning curve, quick start, efficient deployment

Real-time monitoring, quick fault resolution, improves repair time by 30%-60%

Predictive maintenance reduces unexpected downtime by 20%-50%

From time-based routine maintenance to data-driven targeted maintenance, reduces spare parts cost by 20%-50%