Industry Characteristics: Precision electronics manufacturing for small consumer electronics often involves highly automated front-end processes such as modules and SMT, demanding high precision in equipment processing, complex equipment systems, and a prevalence of foreign-made machinery. Final assembly lines, involving tasks like wire plugging, pasting, and casing assembly, are mostly manual production lines with many non-standard self-made and testing equipment. In-house automation design and transformation capabilities are one of the company's core strengths. Customer Needs: · Significant efficiency variations exist among front-process equipment including SMT, woodworking machines, and injection molding machines, both at single-unit and line levels. Data collection and analysis are expected to compare and improve these differences. · Improve maintenance and repair efficiency · Enhance asset management and control capabilities · Further improve SMT material discard rate and fault analysis capabilities

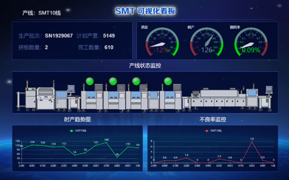

Gechuang Dongzhi introduced the Dongzhi Equipment Health Management Gmaint product for Tonly Electronics, implementing data collection for key front-process equipment such as woodworking machines and SMT. Modules including equipment files, work order management, mobile maintenance, equipment fault tree analysis, and spare parts management were deployed. Automatic material calling and equipment dashboards were achieved through automatic data collection from chip mounters and customized extensions.