The sudden COVID-19 pandemic has swept the nation, and the manufacturing industry faces challenges such as epidemic control, material shortages, personnel shortages, and supply chain risks. As enterprises gradually resume production, manufacturing units, being gatherings of personnel, become key points for epidemic prevention and control. During the epidemic, how to build a systematic epidemic prevention and control system while ensuring employee safety, complete business collaboration in production, and further enhance the enterprise's intelligent technology are issues that manufacturing companies need to resolve to quickly respond to market demands.

The Intelligent Epidemic Prevention and Control Platform Solution, developed based on DongZhi IoT Platform and Mobile Platform, addresses the characteristics of manufacturing parks and factories, such as large crowds, limited staggered entry/exit times, high traffic, and complex usage environments. Through mobile apps, WeChat mini-programs, environmental sensors, high-precision infrared thermometers, and other terminal devices, it collects and statistics environmental, personnel, and material-related epidemic prevention information, providing a comprehensive overview of the park's epidemic prevention progress. The solution covers 8 core epidemic prevention scenarios in factories, helping enterprises achieve intelligent and routine epidemic prevention work, including full-process data collection for returning employees, real-time monitoring and warning of abnormal cases, targeted disinfection of key areas, and summary display of epidemic prevention information.

The Factory Remote Work Solution meets the remote work needs of the manufacturing industry. Addressing the complex issues of remote collaboration, numerous offline scenarios, high demand for mobile operations, complex usage environments, and frequent network switching in manufacturing, it is developed based on DongZhi Mobile Platform, Video Communication Platform, and Industrial IoT Platform. Through instant messaging apps, video conferences, call centers, smart helmets, VR glasses, lossless audio and video compression and noise reduction technology, and various mobile and fixed screen terminals, it provides comprehensive hardware and software integration for remote collaboration in factories. The solution covers 5 major functions: online office, mobile operations, individual and large video conferences, online customer service, and online approval, and provides SDK packages for integration with existing enterprise systems, offering a seamless integration solution for employees.

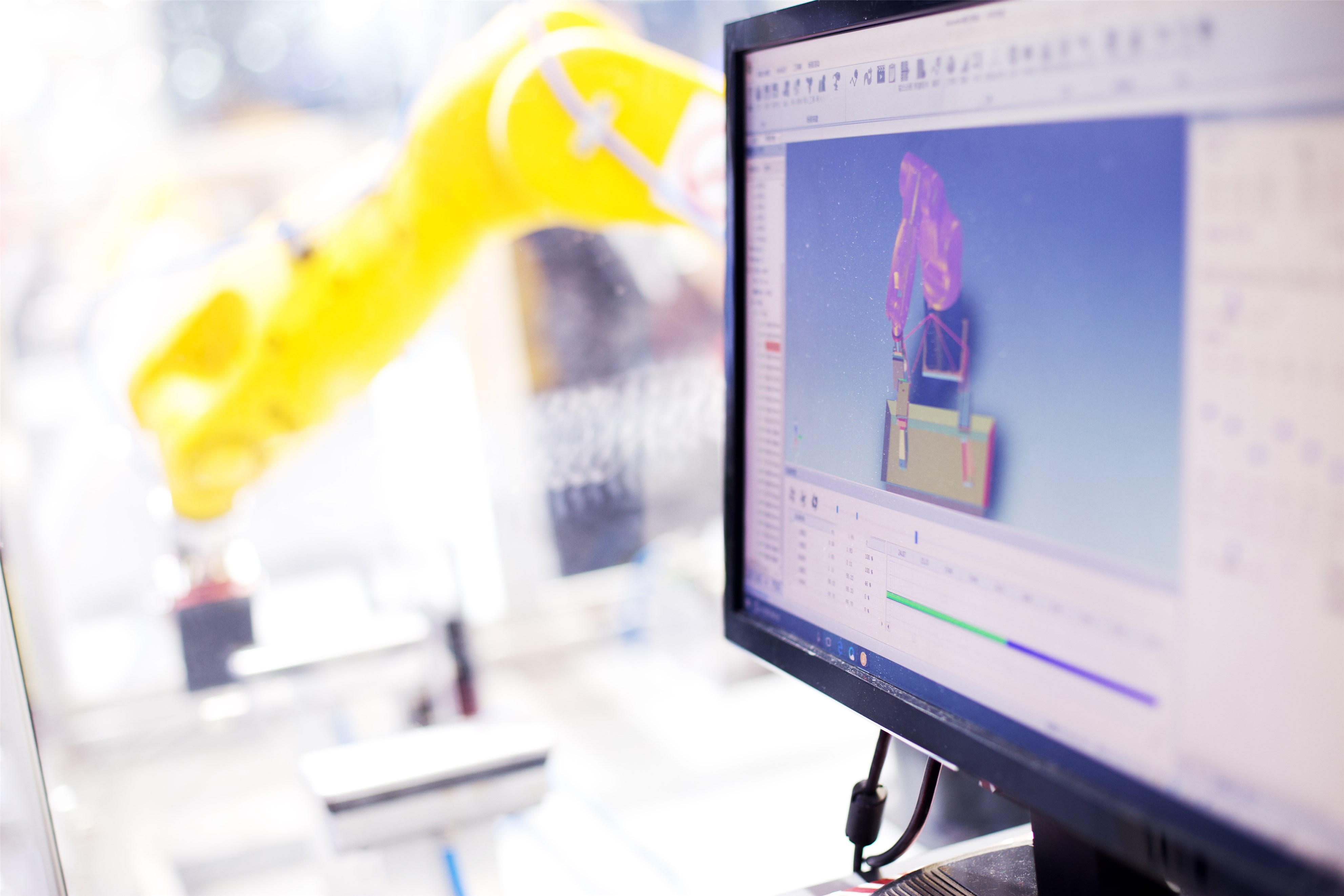

The Equipment Management and Remote Service Solution, integrated and developed based on DongZhi IoT Platform, Mobile Platform, and Office Collaboration Solution, meets the needs for mobile and remote maintenance, as well as targeted and predictive maintenance management of new-generation equipment. Addressing the current situation where factories have purchased 4.0 equipment but still maintain 2.0-level equipment maintenance, it provides an equipment health management system and data-based equipment health management functions based on standards. In response to the epidemic impact, the solution offers remote debugging and diagnostic services by equipment experts, along with an online expert database and equipment maintenance knowledge base.

The Production Visualization Solution, integrated and developed based on DongZhi IoT Platform, Big Data Platform, Mobile Platform, and various application systems, bridges the last mile of digitalization, meeting the needs of personnel at all levels for on-site monitoring and decision-making. The solution integrates various equipment and production data from industrial sites, as well as data from existing enterprise systems, allowing users to quickly customize various business reports and monitoring pages through provided reporting tools and built-in report templates. In response to the epidemic impact, engineers and factory management personnel can remotely and mobilely monitor production operations.

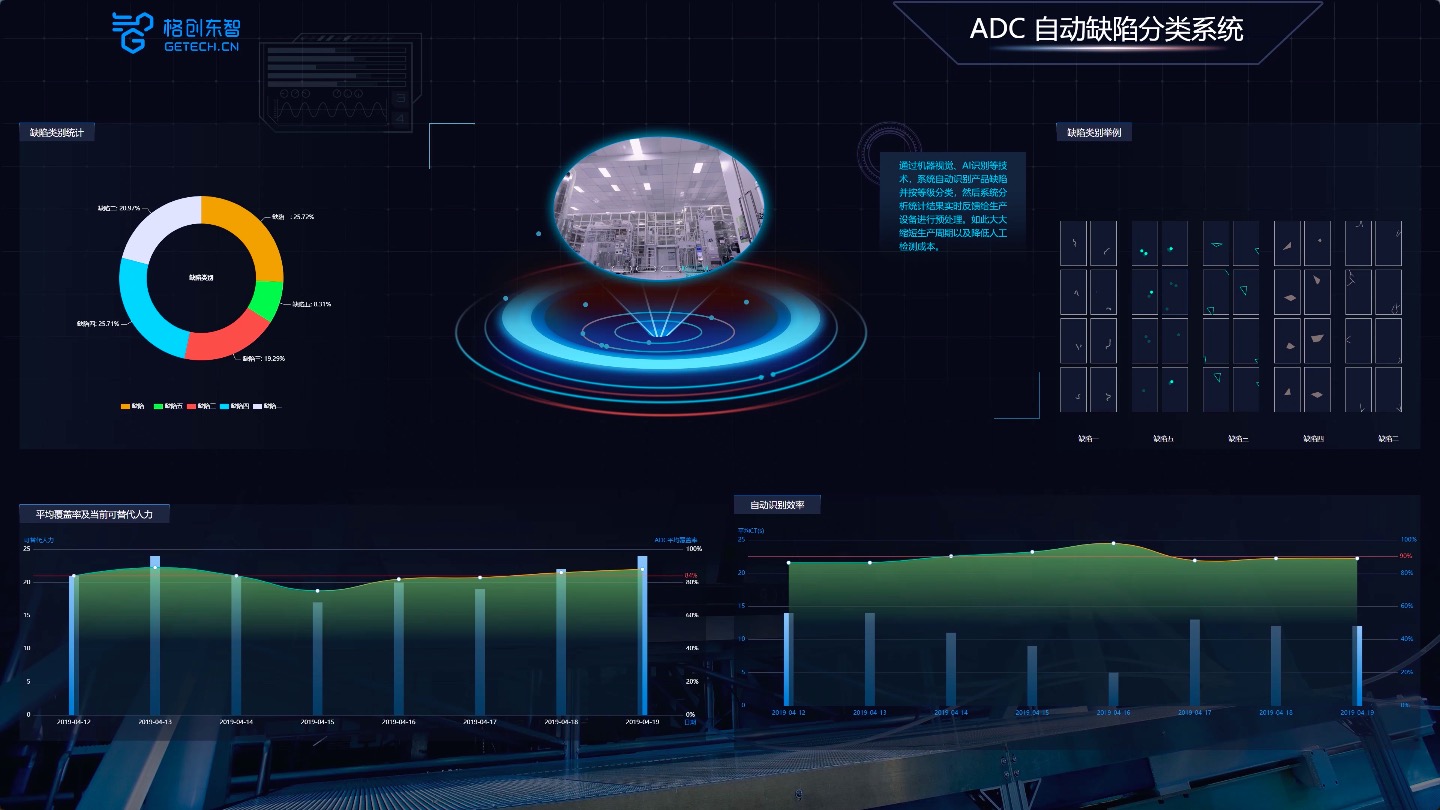

The epidemic has slowed population mobility, and enterprises will face more severe labor shortages. The Intelligent Labor-Saving Solution, through digital and intelligent means, replaces on-site personnel that are difficult to reduce through traditional methods such as automation and lean production. It is developed based on DongZhi Intelligent Platform and AI visual algorithm framework. The solution can be applied to logistics equipment to achieve unmanned smart warehouses with autonomous navigation, trackless AGV delivery, and intelligent sorting for inbound and outbound operations. Applied to appearance inspection, it enables automatic identification and classification of fine appearance defects, replacing manual inspection. In response to the epidemic impact, it can minimize the factory's reliance on manual labor.