SEMICON China | GTRONTEC Xiao Changbao: Innovative Technology Drives Semiconductor Factory Yield Improvement

On June 29, the industry's largest annual semiconductor event—SEMICON China 2023—grandly opened at the Shanghai New International Expo Center. Xiao Changbao, General Manager of the Semiconductor Business Unit at GTRONTEC and an expert in semiconductor intelligent manufacturing, was invited to attend the forum on 'Future Factory' for semiconductor intelligent manufacturing at the conference, where he delivered a keynote speech. He shared insights on how to use innovative technologies and build a new generation of intelligent semiconductor factories to achieve the pursuit of ultimate yield in semiconductor factories amid increasingly complex process technologies.

Xiao Changbao, General Manager of the Semiconductor Business Unit at GTRONTEC and an expert in semiconductor intelligent manufacturing

With the continuous technological upgrades and equipment evolution in the semiconductor industry, wafer manufacturing processes are advancing rapidly, transistor density is multiplying, and the difficulty of chip manufacturing yield management is growing exponentially. Especially in wafer fabs pursuing advanced processes, while striving to balance mass production pressure and yield indicators, the complexity of yield management continues to increase.

Semiconductor factories regard product yield as their lifeline, and its importance is self-evident. Xiao Changbao pointed out that driven by Moore's Law, chip processes are continuously advancing. Chips using new processes are smaller in area, have better power consumption, higher frequency, and lower cost. Data shows that even if each process step on a wafer fab production line has a yield as high as 99%, after 600 steps, the overall yield is only 0.24%, almost zero. Every 1% increase in yield means an additional $150 million in profit for the wafer fab.

"In the semiconductor manufacturing process, common factors affecting yield include material quality, process parameters, equipment status, environmental conditions, personnel skills, etc., distributed across all aspects of 'man, machine, material, method, environment, and measurement,'" Xiao Changbao stated. This also leads to increasingly severe challenges in yield improvement for semiconductor factories. For example:

Many process steps, difficult process control; precise equipment, difficult control; step-by-step inspection, high inspection costs; talent shortage, difficult knowledge reuse; large amounts of data, difficult application; delayed identification of quality issues; complex root causes, delayed traceability...

Against this backdrop, focusing on all aspects such as design, production, improvement, and inspection, and leveraging emerging technologies like AI and big data to achieve higher yield with less investment has become an industry consensus. More and more semiconductor companies are using data intelligence technology for full-chain data analysis in production, finding decision-making and improvement conditions through analytical models, and adopting more flexible and convenient working modes to solve inherent issues in production efficiency, stability, and yield.

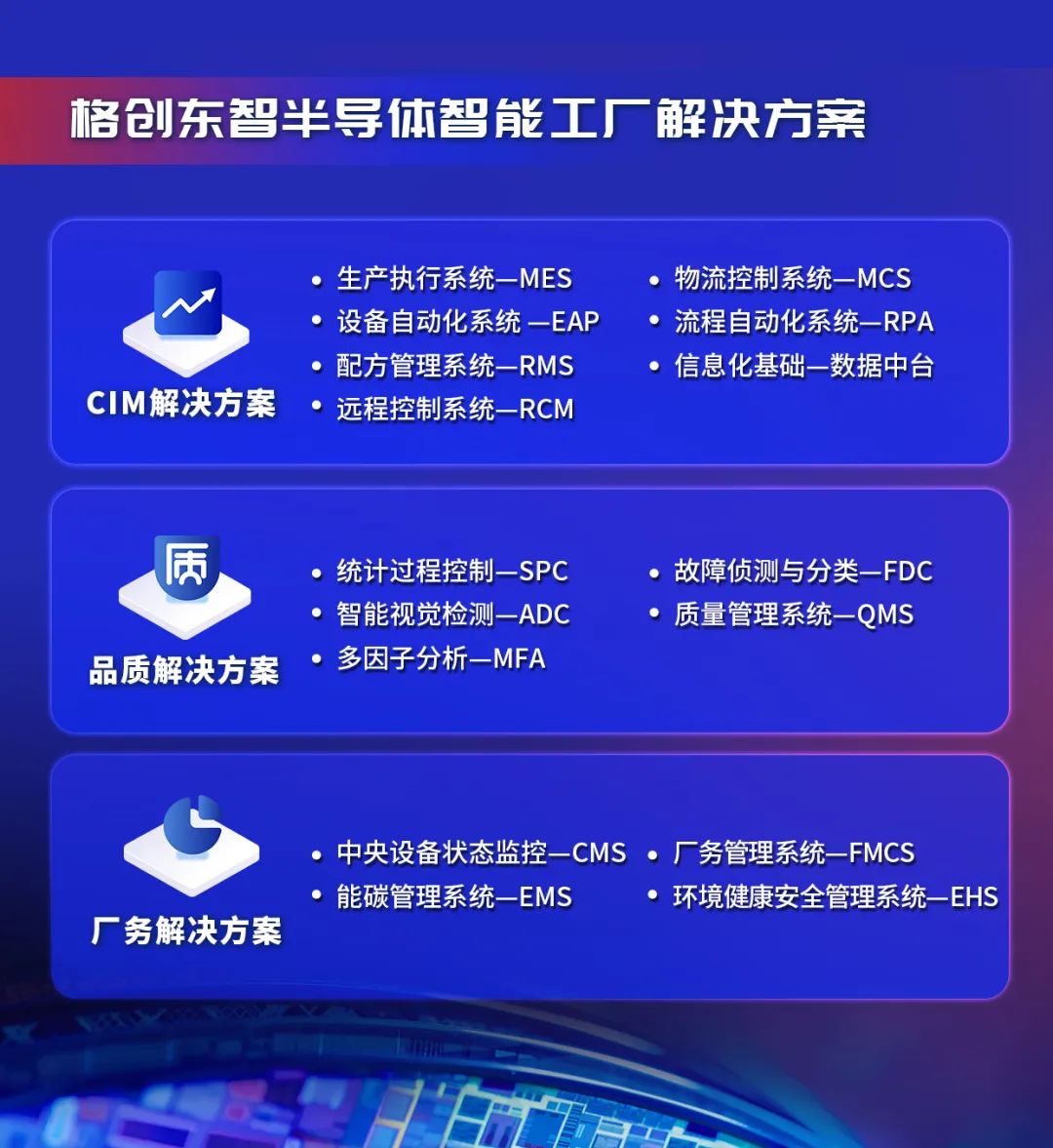

As an overall solution provider for intelligent manufacturing in semiconductor factories, GTRONTEC offers a fully localized full-stack yield improvement solution, including SPC statistical process control, FDC fault detection and classification, MFA multi-factor analysis, ADC intelligent visual inspection, and QMS quality management system. Through an integrated one-stop solution, it helps wafer fabs effectively enhance quality management and solve yield management challenges:

SPC Statistical Process Control:

Diversified data access: automatic instrument and equipment data collection, automatic data file reading, custom data entry, multiple database interfaces;

Efficient calculation: real-time linkage with process data, real-time indicator calculation, complex statistical chart presentation, automatic control line updates;

Real-time monitoring and alerts: real-time alert sending, automatic feedback for shutdown, real-time monitoring dashboard, process capability analysis;

Flexible system design: independent data processing programs, adjustable data collection frequency, data simulation capability, expandable functionality;

FDC Fault Detection and Classification:

Fast response: adopts a new big data architecture, improving processing performance by 10 times. Unlimited number of devices, elastic scaling, quick response;

Fast analysis: new user interface, personalized data dashboard, one-click management of thousands of instances, rapid analysis of product anomalies;

Fast application: foolproof system deployment guidance, simple and convenient configuration, quick configuration even for system logic changes, no coding required;

MFA Multi-Factor Analysis:

Zero code: zero-code modeling, enabling analysis without IT technical background;

Traceable: visual modeling, traceable analysis modeling process;

Predictive: real-time prediction monitoring, anomaly pre-warning and alerting, serving actual production;

Self-learning: autonomous model updates, self-learning iteration;

ADC Intelligent Visual Inspection:

Based on deep learning algorithms, deployed on traditional AOI/CCD equipment, helping traditional AOI/CCD equipment automatically classify product defects. It can achieve autonomous optimization of inspection methods, completely replacing manual re-judgment in traditional machine vision, providing industry with never-tiring eyes and a brain;

QMS Quality Management System:

Comprehensive, whole-process, full-lifecycle quality management: integrates comprehensive quality management with product full-lifecycle quality management, and vertically connects quality data chains from group companies to subsidiaries, departments, teams, and shifts;

Fully integrates with other information systems, eliminating information silos: seamless integration with PLM, SAP, MES, SRM, CRM, and other systems, achieving business continuity and eliminating information silos;

Microservices architecture, flexible deployment: built on a microservices architecture, cross-platform support for operating systems and databases, BS + mobile client approach; supports local deployment and SaaS cloud deployment;

Currently, semiconductor factories have an increasingly urgent demand for intelligent manufacturing upgrades. GTRONTEC is not only proficient in industrial software and system R&D for cutting-edge manufacturing such as semiconductors but is also one of the few leading domestic manufacturers providing full-stack factory integration services.

Based on the new perspective of 'production-analysis-prediction,' GTRONTEC has built a fully localized full-stack CIM overall solution for semiconductor intelligent factories, achieving transparent production execution, automated equipment management, efficient plan coordination, precise quality traceability, and logistics management. This helps semiconductor companies increase capacity, reduce losses, improve yield, and optimize production and process design. Currently, GTRONTEC has successfully served semiconductor industry clients such as SMIC, SAIC Infineon, Wuhan Xinxin, Zhuzhou CRRC, Yangjie Technology, and Li Auto-Sico Semiconductor.