GeChuang DongZhi He Jun: Before the Next Expansion Wave, Battery Manufacturers Should 'Repair the Umbrella on a Sunny Day'

After more than a decade of development, China's new energy battery industry has entered a fierce battle stage of 'two superpowers and many strong players', especially this year, market competition has reached a white-hot level, which can be described as entering the 'midfield battle'. In terms of technology and material cost reduction, manufacturers are becoming increasingly similar, making manufacturing cost reduction more important, and digitalization and intelligence are being elevated to a higher status. In the midst of intense competition, how can manufacturers further develop through competition and cooperation?

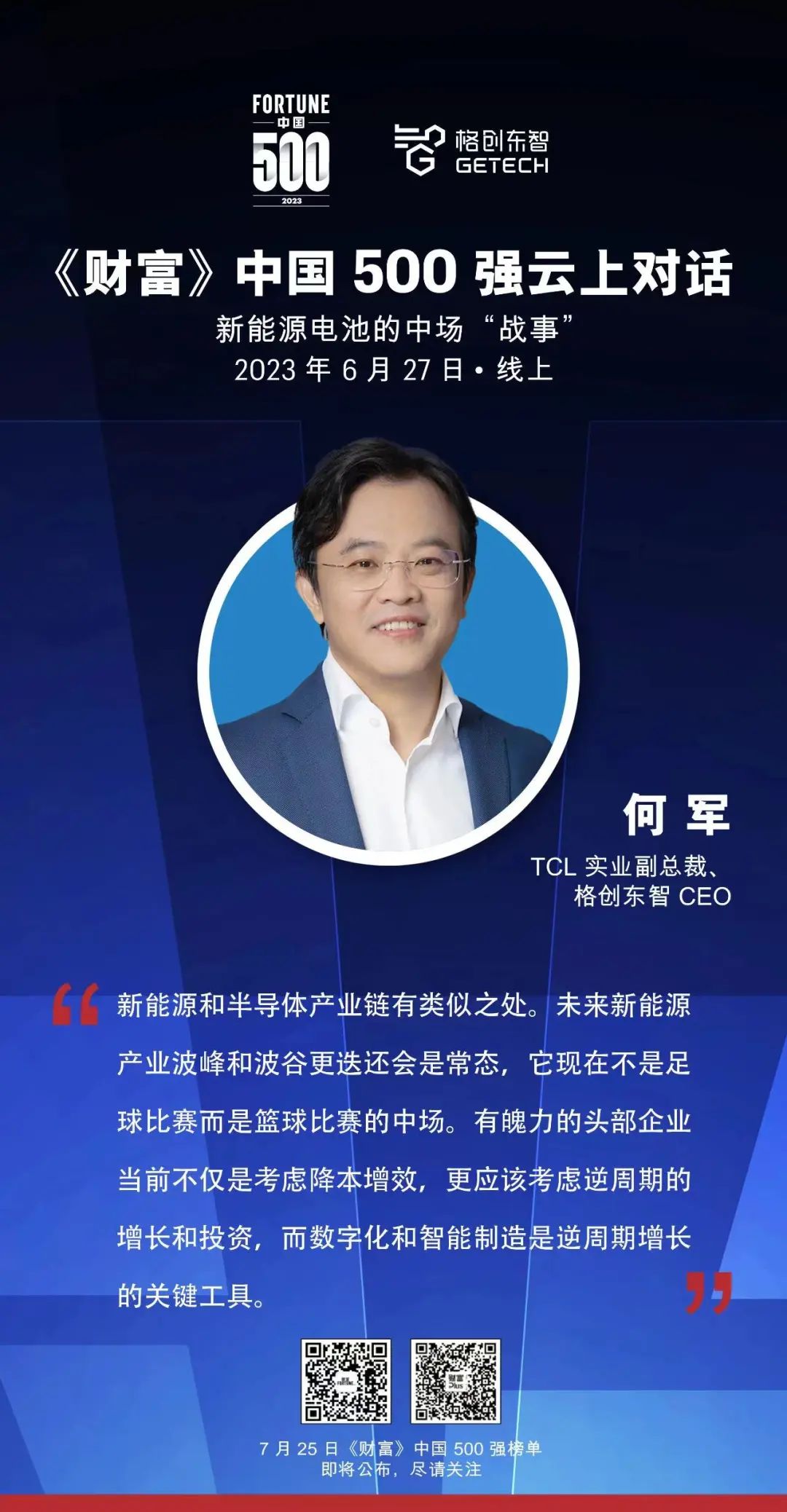

Recently,TCL Industries Vice President and GeChuang DongZhiCEO He Jun was invited to attend the Fortune China500 Cloud Dialogue, exchanging views with Xiamen Tungsten New Energy Director and General Manager Jiang Long, Honeycomb Energy Vice President Yin Dongxing, and Ruipu Lanjun Energy Vice President Yu Zhaoyu. They discussed industry cycles, technological innovation, manufacturing cost reduction, and global expansion, sharing latest trends and insights.

He Jun stated that under the normalization of industry peaks and troughs, the battery industry should consider the following points:

First, truly visionary leading companies should not only focus on cost reduction and efficiency improvement, but also consider counter-cyclical growth and investment, mainly targeting key customers for strategic investments.

Second, companies should focus on relative competitiveness, meaning compared to peers, when a trough comes, they lose less, and when a peak comes, they profit more and capture new opportunities faster.

Third, companies should consider changes in the entire model, transforming from cost-driven to efficiency-driven, from investment-driven to technology or innovation-driven, and digitalization and smart manufacturing can be key tools for achieving counter-cyclical growth.

He also pointed out that companies should 'repair the umbrella on a sunny day', because when facing cost pressure to reduce costs and improve efficiency, many measures are short-term and may not be effective. Truly effective cost reduction requires long-term innovation, such as process innovation and equipment upgrades, which take time. Promoting intelligence also requires a long cycle. The core is lean thinking and concepts to enhance smart manufacturing effects, driven by business needs like quality management, equipment management, production control, energy and carbon management, and supply chain, using new technologies to improve various areas.

At the same time, lean requires top-level planning, not a complete blueprint, but end-to-end supply chain planning and quality traceability matching. Top-level planning should be goal-oriented: define the ultimate goal first, then plan technology. He Jun believes that people who only understand technology cannot lead digitalization in manufacturing due to 'technology worship'; those with production experience should be responsible.

Furthermore, digitalization should not overemphasize manufacturing and neglect operations. Today, digitalization within factories and operational models should advance together for centralized control of cross-regional plants.

Third, do not overemphasize systems and neglect people. The core of digitalization is people; front-line engineers key in highly automated companies. Digitalization should empower them from their perspective for continuous implementation and innovation.