Dongzhi Platform New Upgrade: GTRONTEC and TCL Global Ecosystem Partners for Smart Manufacturing High-Quality Development

On July 6, 2023, the TCL Global Ecosystem Partners Conference was grandly held in Wuhan. The conference gathered over 500 representatives and partners from global industries such as smart terminals, semiconductor displays, and new energy photovoltaics to discuss technological innovation and building a sustainable high-tech manufacturing ecosystem. At the conference, TCL announced the upgrade of Hubei's first national-level cross-industry platform, and GTRONTEC officially settled in Wuhan.

As an industrial internet platform strategically incubated by TCL, GTRONTEC brought together global ecosystem partners and industry experts to explore technological innovations and build an open, win-win ecosystem focused on smart manufacturing.

Cross-industry Upgrade

Collaborating with Wuhan to Build a New Smart Manufacturing Ecosystem

The conference featured the upgrade ceremony of Hubei's first national-level cross-industry platform and the settlement of GTRONTEC. GTRONTEC, with its newly upgraded Dongzhi Industrial Application Intelligent Platform (referred to as Dongzhi Platform), officially settled in Wuhan.

In May 2022, the Dongzhi Platform was selected as a national-level cross-industry industrial internet platform by the Ministry of Industry and Information Technology (MIIT), becoming Hubei's first such platform. In June 2023, MIIT conducted research, evaluation, and dynamic assessments of cross-industry platforms, focusing on five dimensions: resource management, core technology, empowerment effectiveness, social contribution, and sustainable development capabilities, including 21 detailed indicators. Under high standards and strict rules, the Dongzhi Platform advanced 6 places in MIIT's dynamic evaluation ranking, entering the TOP 10 and solidifying its position in the national team.

Over the past year, the Dongzhi Platform has grown rapidly, enhancing its technical support and industrial ecosystem cultivation, breaking through core technologies, and promoting the localization of industrial software. It has achieved major upgrades in resource management, application services, and basic technical capabilities.

In resource management, the platform added 105,967 industrial devices, 4,218 industrial models, 2,204 industrial apps, and 9,481 developers in the past year.

In application services, addressing the transformation needs of key industries, GTRONTEC expanded into new sectors like new energy and automotive, adding 8,378 enterprise users through scenarios such as production optimization, management decision-making, resource allocation, and product lifecycle management.

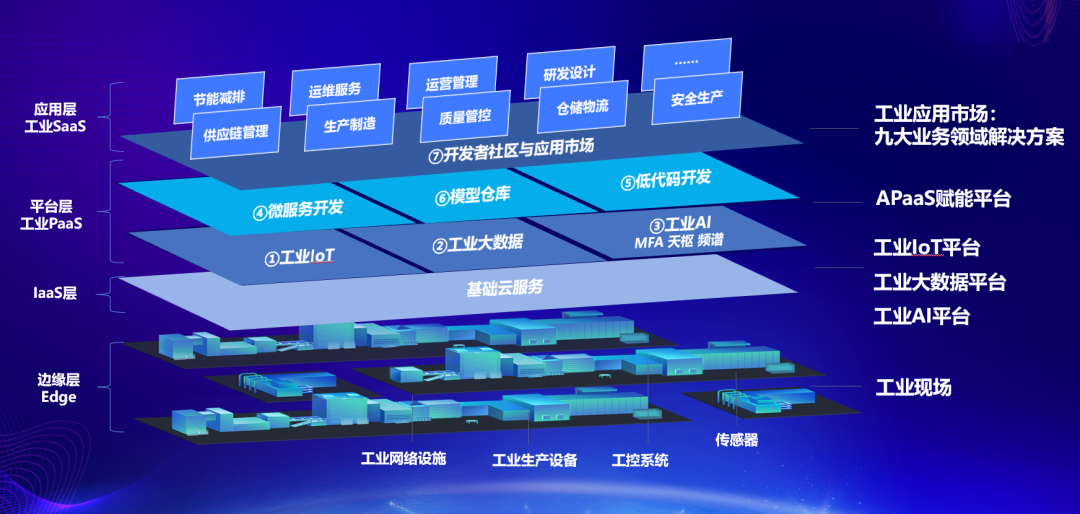

In basic technical capabilities, the platform integrated key technologies like 5G, IoT, industrial AI, big data, blockchain, digital twins, industrial AR/VR, and machine vision, deeply combining them with industrial know-how. It has formed four core technology systems: data integration and edge processing, industrial data modeling and analysis, data management, and platform enablement with microservices.

In providing digital transformation services to industrial enterprises, the Dongzhi Platform uses low-code/no-code development platforms and microservice components to accelerate industrial app deployment, strengthening its empowerment in industrial scenarios.

Currently, Wuhan is actively creating a national high-quality manufacturing development pilot zone, being a key base for China's manufacturing industry and emphasizing digital transformation. This makes it an ideal location for GTRONTEC to deepen the integration of industrial internet platforms with local manufacturers.

Since entering Wuhan in 2019, GTRONTEC has provided digital transformation consulting and technical renovation services to over 500 manufacturing companies, helping them achieve deep intelligent upgrades and win titles like Wuhan's benchmark smart factory and intelligent transformation demonstration projects.

GTRONTEC Exhibition Area: Industrial Applications Based on the Dongzhi Platform

Leveraging the Dongzhi Platform, GTRONTEC built a Central China smart transformation platform based on hybrid cloud deployment, offering integrated services from consulting to system implementation. In the semiconductor field, it launched Hubei's first pan-semiconductor industry platform, serving over 300 upstream and downstream companies and enhancing production management, quality control, and process optimization across the产业链.

After the Dongzhi Platform upgrade, GTRONTEC officially settled in Wuhan and will build its national operations headquarters in two phases. It will continue to leverage Wuhan's policy support, digital transformation environment, and talent to promote digital transformation and high-quality development in Wuhan and Hubei's manufacturing industry.

The upgrade and settlement will accelerate the ecosystem construction of GTRONTEC's industrial internet platform. It will deeply participate in Wuhan's smart manufacturing upgrades, using a 'platform + applications' approach to strengthen advanced manufacturing, empower industrial internet scaling, and drive high-quality development and new industrialization in Wuhan and Hubei.

Building the Foundation of Industrial Interconnection

Ascending to the Heights of Industrial Innovation

He Jun, Vice President of TCL Industries and CEO of GTRONTEC, delivered a keynote report titled 'Building the Foundation of Industrial Interconnection, Ascending to the Heights of Industrial Innovation.' He pointed out that China's manufacturing is transitioning from rapid scale expansion to high-quality development, with digitalization and smart manufacturing being key. Over the past five years, TCL has achieved leapfrog digital transformation to become a global leader, thanks to correct concepts, innovative organization, talent cultivation, sustained investment, and an open culture.

"GTRONTEC has witnessed TCL's transformative digital journey, honed in TCL's rich manufacturing scenes, and built a national cross-industry industrial internet platform, contributing smart manufacturing products and solutions to the industry chain. As a foundational partner in industrial internet, GTRONTEC is eager to share experiences and expand cooperation with TCL's上下游产业链 to help ecosystem partners succeed."

He Jun introduced that as a cross-industry industrial internet platform originating from semiconductors, GTRONTEC supports smart manufacturing across multiple industries. It connects industrial production elements southbound and provides a rapid development foundation for industrial data intelligence applications northbound, while collaborating with partners to build an industrial internet operating system. Technically, it productizes core capabilities like IoT, big data, AI, and low-code with TCL Research Institute and external partners.

He Jun stated that in the future, Gechuang will focus on promoting the smart factory operating system, developing full-stack pan-semiconductor industrial intelligence solutions, creating digital zero-carbon enterprises and smart parks with AI energy-carbon solutions, and cultivating industrial geeks with academia, industry, and government to build a multi-level innovation ecosystem and reach new heights in digital transformation. It will also actively participate in TCL's Green carbon neutrality initiative, contributing digital力量 to carbon neutrality goals.

Widespread Media Attention

Hot Topics in the Industry

During the conference, He Jun was interviewed by media outlets such as Xinhua News Agency, Hubei Daily, Daily Economic News, Southern Metropolis Daily湾财社, First财经, and 21st Century Business Herald, sharing insights on China's industrial software development and semiconductor industry cycles.

In recent years, domestic industrial software and operating systems have advanced rapidly. He Jun believes that software has entered an intelligent stage, defining factories to achieve智能化. "With national promotion, more Chinese players are emerging in industrial software, showing increased awareness. Future smart factory construction should focus on three levels: application intelligence, IT-OT integration via industrial internet platforms, and equipment intelligence. In these areas, especially R&D software, CIM software, and equipment software, the proportion of domestic products needs further improvement."

When discussing whether the semiconductor downturn challenges industrial internet companies, He Jun said the cycle is longer than expected but presents opportunities for companies like GTRONTEC. "During growth phases, the focus is on rapid factory building and capacity expansion, often using foreign equipment without giving domestic companies a chance. In downturns, companies innovate in existing factories for cost reduction and efficiency, emphasizing strategic supply chain management. This downturn offers Chinese software companies opportunities to collaborate on independent innovation with semiconductor firms."