GTRONTEC's Digital Strategy in Dual Tracks of Power and Energy Storage—Replication

Summary

As the power battery competition reaches the mid-stage, the key is no longer production capacity but cost-effectiveness and quality. Extreme cost reduction and efficiency improvement are needed to meet challenges.

Recently, the 16th High-Tech Lithium Battery Industry Summit and the 2023 High-Tech Energy Storage Industry Summit were held in Changzhou. As a digital intelligence provider in the new energy industry, GTRONTEC showcased its new energy smart manufacturing solutions and benchmark smart factory construction experience at both events.

With the global energy transformation advancing rapidly, facing adjustments such as structural overcapacity, scale manufacturing upgrades, energy crises, and zero-carbon transitions, the entire new energy industry chain should actively embrace changes, tackle challenges, and break through uncertainties.

In the lithium battery industry, competition is gradually entering the latter half, with risks of overcapacity in the supply chain. Dr. Li Nan, General Manager of GTRONTEC's New Energy Business Group, pointed out in his speech that in recent years, the core task of lithium battery factories has been to increase production capacity and expand output. Now, in the "mid-stage battle," the focus is no longer on capacity but on cost-effectiveness and quality. Extreme cost reduction and efficiency improvement are essential to address challenges.

Li Nan believes that lessons can be drawn from the泛 semiconductor industry. Under full load, high yield rates, and full production and sales, digitalization and intelligence should be prioritized. Through applications like industrial internet, extreme yield rates, efficiency, and cost reduction can be pursued. Specifically, Li Nan suggested:

Extract quality capacity from old factories: Enhance process and quality stability through data-driven production control, process and quality optimization, and integrated equipment engineering management to achieve quality capacity.

Accelerate ramp-up speed for new factories: Incorporate smart manufacturing concepts early, establish standards for new factory construction, and shorten construction and ramp-up time for domestic and overseas new factories.

Enable rapid iteration in R&D: Use big data to accelerate parameter optimization in R&D, shift from "reverse design" to "forward design," and shorten product development time.

Optimize energy for cost savings: Actively adopt green electricity like rooftop photovoltaics; deeply integrate into energy usage scenarios, combine management with technical upgrades, use AI for energy-saving optimization, manage and reduce carbon emissions, and improve ESG management.

As a globally competitive new energy digital intelligence service provider, amid the "mid-stage battle" in the lithium battery industry, GTRONTEC will leverage its digital technology and practical experience to help more lithium battery companies strengthen their internal capabilities, win the latter half, and achieve sustainable growth.

In the photovoltaic energy storage field, with advancements in technology and cost reductions, photovoltaic energy storage systems are expected to become a major energy form in the future, facing more opportunities and challenges.

Song Hao, Senior Director of GTRONTEC's Photovoltaic and Energy Storage Business, stated in his summit speech that photovoltaic energy storage requires high construction standards and stable operation, necessitating intelligent operation and maintenance management. Solving these issues requires efforts in technological R&D, policy support, and market promotion within the industry.

GTRONTEC always aligns with national development, vigorously promoting the sustainable development of green and clean energy. By modularizing industrial knowledge and experience accumulated over years in high-end manufacturing, and based on IoT, big data, and AI platforms, GTRONTEC has built an operation and maintenance platform for the entire photovoltaic and energy storage sector. This helps the photovoltaic industry further integrate with new-generation information technology, entering the intelligent era smartly, efficiently, safely, and reliably.

Song Hao introduced that GTRONTEC's photovoltaic intelligent operation platform provides secure and reliable communication connectivity for photovoltaic equipment, offering data collection, rule engine, data visualization, and inspection services—a one-stop IoT solution to maximize project benefits. Through AI fault diagnosis, it reduces manual inspection costs, accurately locates anomalies, and enables timely maintenance to achieve cost reduction and efficiency improvement.

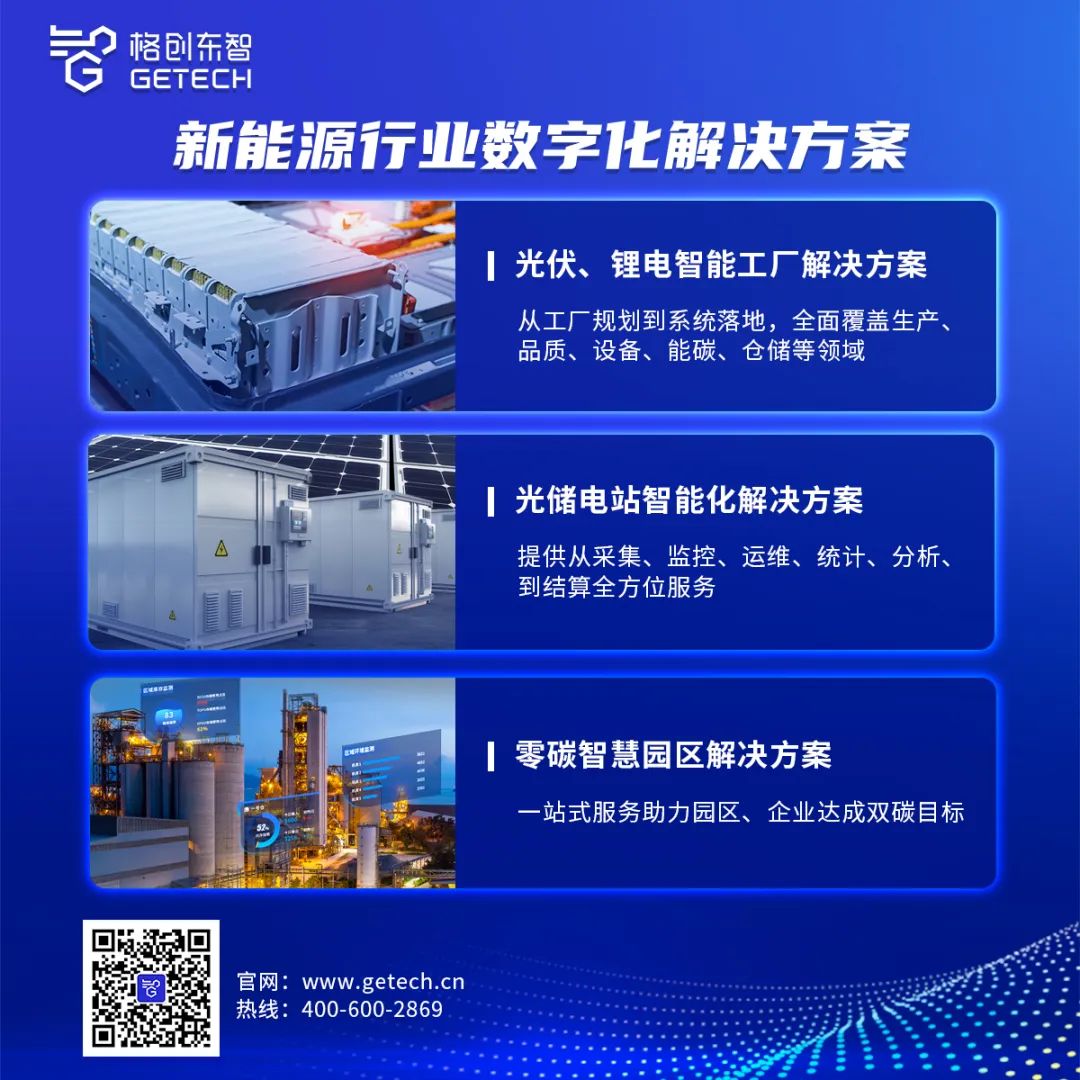

Relying on standardized platforms, industrial applications, and industry solutions, GTRONTEC addresses multiple scenarios such as production, equipment, quality, energy, and logistics, providing smart factory solutions for new energy companies. This includes full-chain services from consulting and planning to system software implementation, helping new energy companies build benchmark smart factories.

Currently, GTRONTEC's services cover the entire new energy industry chain, providing tailored smart manufacturing solutions for lithium battery materials, equipment, battery manufacturing and recycling, as well as photovoltaic cells, components, and power stations. It has created multiple industry benchmark cases, aiding the new energy industry in achieving intelligent and green sustainable development.