GTRONTEC Case | GQMS Helps Enterprises Achieve High-Quality Digital Transformation and Quality Operation Management Platform Upgrade

In manufacturing, quality management has always been an eternal theme in enterprise management. To improve quality management, enterprises must master sufficient, useful, and product-quality-close data and information, using digital means to enhance quality management.

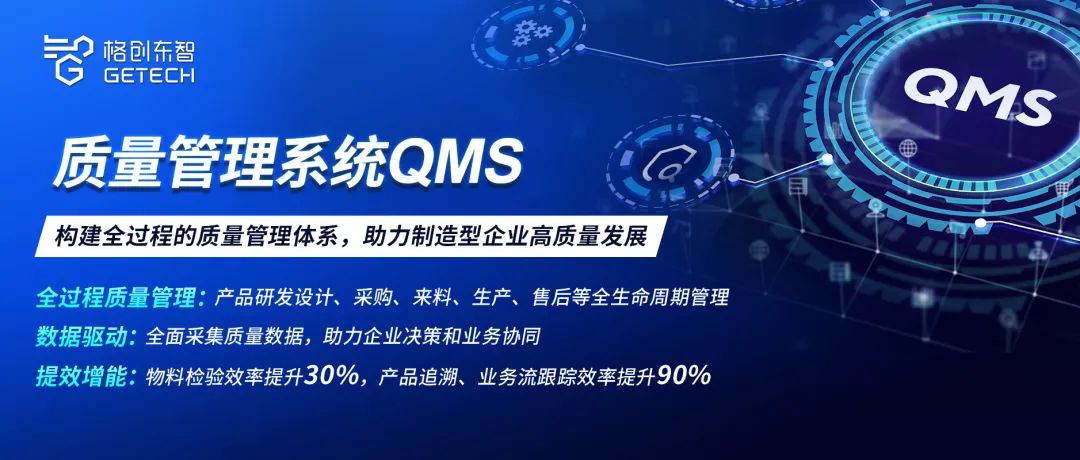

QMS (Quality Management System) is one of the most representative digital applications in the field of quality management. Its core advantage lies in enabling full lifecycle quality management for groups and products. Through data collection and entry, it deeply mines and summarizes originally discrete and implicit quality data, providing effective data support for quality control throughout the product lifecycle.

Taking GTRONTEC GQMS as an example:

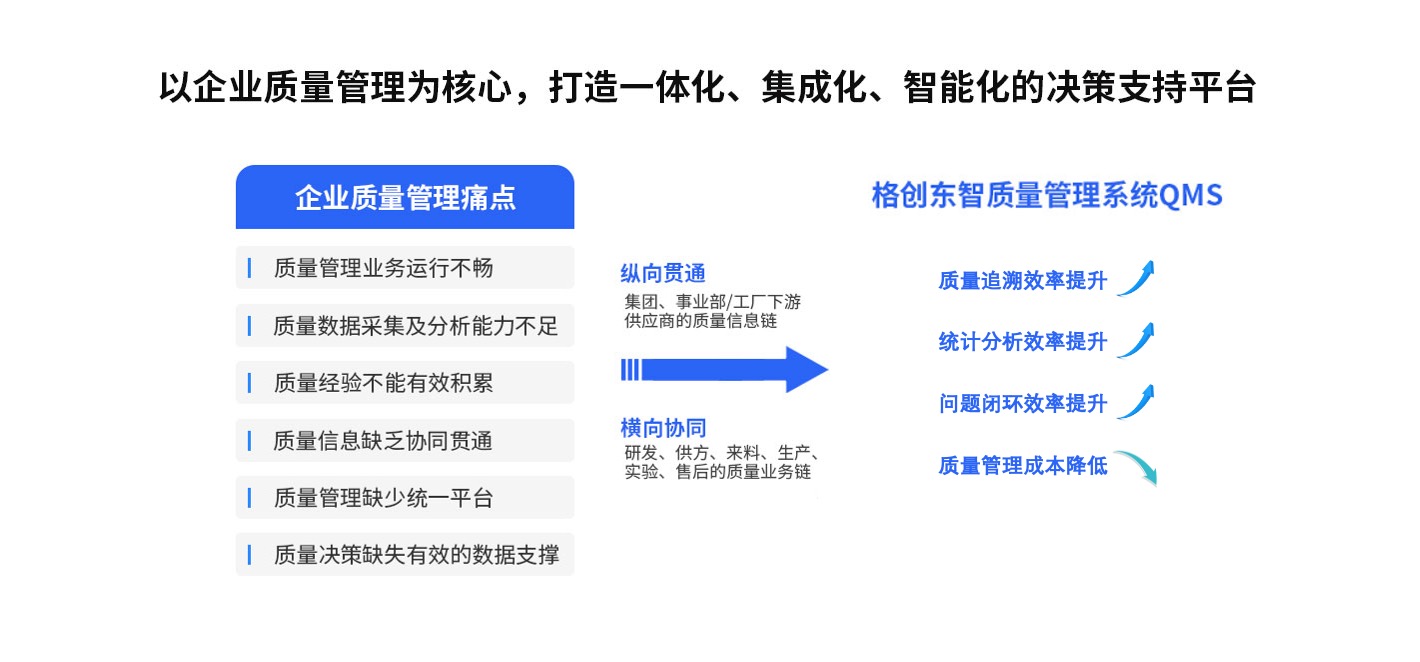

Vertically, it integrates the quality information chain across groups, subsidiaries, institutes, and factories; horizontally, it coordinates the quality business chain involving R&D design, procurement, incoming materials, production, testing, and after-sales.

Thus, it builds a quality management-centric, integrated, intelligent planning, control, and decision support platform, achieving networked quality work, effective closure of collaborative quality events, intelligent application of quality information, full sharing of quality experience, and全面提升 quality control capabilities.

Case Analysis

A company engaged in the R&D, production, and sales of polymer vibration-damping and noise-reduction products, as well as polymer composite modified materials, has established quality document and audit management systems, quality monthly report data submission platforms, and developed quality modules in SAP and MES since 2011, basically achieving informatization and paperless operations for core quality businesses.

However, the limitation is that these quality business information systems only partially achieve informatization or semi-informatization, failing to achieve full value chain integration of quality data, with low levels of analysis and application, making it difficult to provide effective support for business decisions. The main issues are:

>Quality data is frequently relocated, hard to find, difficult to understand, challenging to access, and unreliable;

>Existing quality-related information platforms are scattered, with insufficient data mining and limited value creation;

>Inadequate rigor in quality traceability, lack of integration in quality异常 information, delayed quality information transmission and processing, and low efficiency in quality data statistics;

>Data silos exist,难以 supporting digital transformation, on-demand data sharing, agile self-service, and secure compliance requirements for timely quality data management.

The above issues constrain the efficiency and effectiveness of the company's quality management. With the trend of enterprise digital transformation and higher pursuits of quality, cost, and efficiency, establishing a digital quality management platform that achieves concentration, integration, and transparency of quality data is urgent.

GTRONTEC identified the quality elements throughout the product lifecycle of the enterprise, assisted the customer in updating quality strategy, business, talent, culture systems, constructed an L1-L4 quality operation management process architecture, improved the multi-level quality indicator performance operation system of "Group-BU-Factory," and developed a quality digital transformation solution:

First, design the quality-related IT application architecture and peripheral business systems, then select pilot product lines to standardize, structure, informatize, and integrate quality business processes, product quality criteria, quality control gates/valves, and product quality data, gradually extending to other product lines and business domains:

Focusing on product lines and based on the full product realization lifecycle, achieve online data collection, analysis, and application of quality data through the "four modernizations" of quality management planning and implementation, enabling forward transmission and reverse traceability of quality data, and accumulating experience and knowledge;

Using typical product lines as pilots, achieve integration of quality data across the entire business chain, and推广 pilot product line quality digitalization experience to other product lines;

Build quality business informatization functions step by step by module,最终 forming an integrated QMS control platform;

Establish a quality management data cockpit and achieve data integration with other related business systems such as PLM, SAP, MES, SRM, making QMS the integrated control platform for the company's quality strategies, methods, measures, results, improvements, and knowledge accumulation.

With the help of GTRONTEC's GQMS Quality Management System, the enterprise's quality management digitalization achieved a leap forward improvement:

Through integration of GQMS with ERP, MES, WMS, achieve reverse control of product defect handling, preventing perfunctory and失控 situations in the defect handling process;

Through SPC control at key quality nodes, shift from合格 control to process capability preventive management;

Through IQC supplier pre-inspection, reduce the frequency of IQC incoming inspection, cut inspection resource input by over 50%, and shorten the storage cycle by more than 0.5 days;

Through systematic collection and integration of product quality information, achieve over 90% improvement in traceability and tracking efficiency;

Through automatic summarization and statistics of core quality management data by the system, reduce monthly management meeting data statistics time by 5-10 days;

Based on a flexible custom data statistical analysis system, achieve comprehensive application of QC analysis methods such as Pareto charts, histograms, control charts, creating a penetrating data system with over 90% improvement in data statistical verification efficiency.