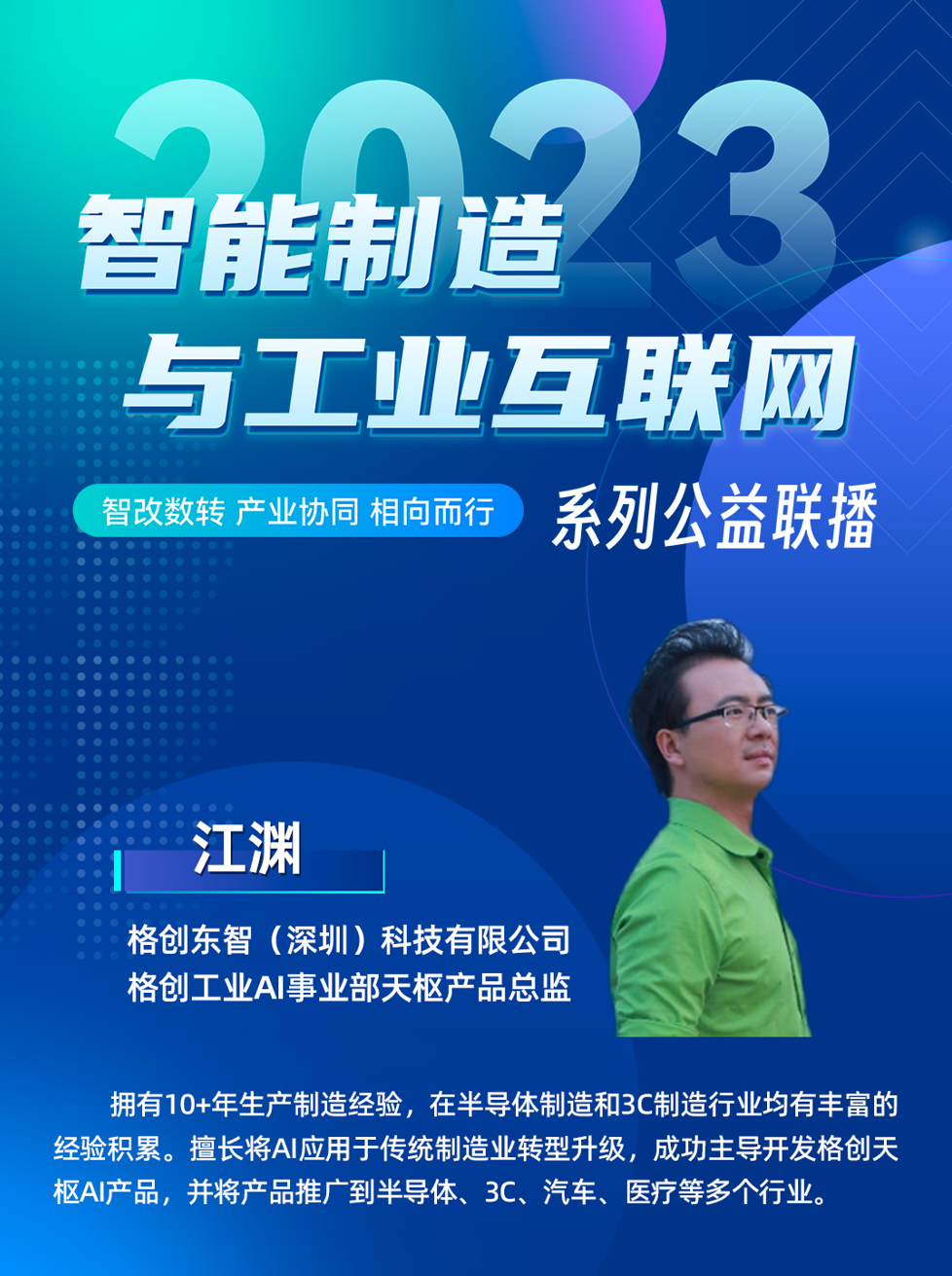

Smart Manufacturing and Industrial Internet Public Welfare Broadcast | GTRONTEC Dongzhi Lecture: AI Vision Boosts High-Quality Development of Manufacturing Industry

Currently, AI plays an increasingly important role in industrial manufacturing, becoming a powerful engine for digital transformation. Especially in quality inspection and data analysis, AI has mature applications.

Jiang Yuan introduced that industrial AI technology can be applied to various areas of production manufacturing, such as quality inspection, material traceability, behavior recognition, and visual-guided assembly, enhancing production line intelligence, reducing manual work, improving safety, ensuring quality stability, and speeding up production.

For example, quality inspection has always been a critical link in manufacturing. A minor defect can affect overall production yield, and if it enters the market, it may cause unimaginable safety risks. Traditional inspection relies heavily on manual labor, with issues like long training cycles, high costs, inconsistent standards, and low accuracy. With the digital era, technologies like AI and IoT are being applied to traditional inspection, helping to upgrade it, free up productivity, and achieve cost reduction and efficiency improvement.

GTRONTEC Dongzhi Tianshu AI Vision Inspection System specializes in industrial AI inspection for semiconductor display, new energy photovoltaic, and 3C manufacturing, featuring an integrated industrial vision deep learning engine with sensing, storage, computation, and cognition, creating a unified data collection solution with image, video, and optics, and establishing a 360-degree data information database. It includes a millions-level industry feature database to improve inspection accuracy and has a multi-task, composite toolkit covering various industrial inspection scenarios.

Currently, GTRONTEC Dongzhi Tianshu AI Vision Inspection System has been applied in multiple industrial scenarios. Based on this, the ADC (Artificial Intelligence Automatic Defect Classification) system implemented in TCL CSOT production lines is the first truly deployed AI application in China's semiconductor display industry. Compared to traditional manual inspection, the ADC system greatly improves inspection efficiency, replacing over 50% of manual labor; AI recognition speed increases 5-10 times, accuracy rises from 85% to over 90%, and it is expected to bring TCL CSOT an annual benefit of 15 million yuan.

In recent years, GTRONTEC Dongzhi has established partnerships with several leading companies for AI vision inspection projects. For example, the 'AI Replacement Solution'—Online Intelligent Quality Analysis System—developed for Gree Electric, a leader in the 3C electronics industry, applies the Tianshu AI Vision Inspection System to Gree's SMT production lines to inspect SMT placement and reflow soldering quality, reduce misinspection rates of post-reflow AOI equipment, cut manual re-inspection labor, enable device interaction for real-time monitoring, and accurately analyze product quality to output quality information for分流 control and quality analysis reports for improvement.