CIIE Smart 'Chip' Technology Seminar | GTRONTEC Large Model Empowers Semiconductor Smart Factory

On September 20, the sub-forum of the China International Industrial Expo—Smart 'Chip' Technology Seminar was held in Shanghai, bringing together experts, scholars, and corporate representatives from academia, industry, and research institutions to explore the application and prospects of chip technology in smart manufacturing. Ma Wei, Deputy General Manager of GTRONTEC's Semiconductor Division, was invited to attend the seminar and delivered a keynote speech, sharing the development and application of large models in semiconductor smart factories.

With the continuous advancement of technology and the rise of smart manufacturing, chip technology plays a key role in smart manufacturing. As a core component of modern industry, chips drive the digital transformation and intelligent development of manufacturing. The goal of smart manufacturing is to improve production efficiency, flexibility, and quality by integrating advanced technologies and intelligent systems.

Ma Wei pointed out in his speech that in recent years, the development of data models has accelerated innovation in emerging technologies. General large models can be applied to multiple tasks, and their capabilities leap with the increase in model parameters, possessing chain-of-thought reasoning and emergent abilities. At the same time, large models also require high resources such as data and computing power. Many technology pioneers in enterprises are actively working to apply the power of large models + big data in production practices to achieve true 'cost reduction and efficiency improvement, enhanced customer value, and improved user experience.'

For the semiconductor industry, effectively and quickly mining and enhancing the value of massive data is key to the development of smart manufacturing. It requires full utilization of artificial intelligence and big data computing technologies to integrate the entire factory data chain and improve the level of smart manufacturing. The semiconductor industry's pursuit of极致良率 (ultimate yield),极致效率 (ultimate efficiency), and极致成本 (ultimate cost) requires shifting from post-processing to pre-warning and from data/tool-assisted decision-making to automated decision-making actions.

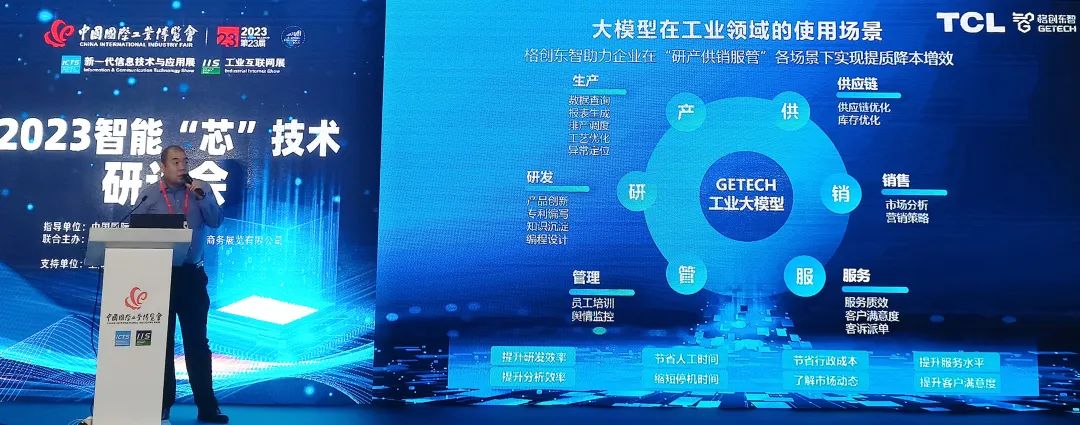

With in-depth exploration of large model technology, GTRONTEC has launched its independently developed industrial intelligent large model engine base—OctopusGPT. Ma Wei introduced that OctopusGPT learns and simulates various rules and processes in industrial production to achieve comprehensive optimization and intelligent control of industrial production processes, helping industrial enterprises improve quality, reduce costs, and increase efficiency in scenarios such as 'R&D, production, supply, sales, service, and management,' accelerating the realization of intelligent production and operations.

Currently, based on the research and innovation of large data models, GTRONTEC has achieved a high level of intelligence in its semiconductor business. GTRONTEC's data intelligence solutions can utilize equipment and business data to drive root cause analysis for quality, pre-warning, reverse control optimization, and automated decision-making, achieving closed-loop management and providing semiconductor factories with one-stop, one-click, collaborative, and shareable data science solutions and tool platforms. At the same time, GTRONTEC also offers a full range of solutions for semiconductor factory construction, including production automation software, full-process quality control systems, logistics automation-related systems, and facility management systems, helping customers build benchmark smart factories.