GETECH: Globally Competitive New Energy Integrated Factory Digital Intelligence Expert

With the global low-carbon transition and the new energy revolution, the new energy industry represented by lithium batteries, photovoltaics, and hydrogen energy is undergoing upgrades and changes. Among them, the lithium battery industry has entered a new development cycle with advantages in global capacity, technological innovation, and supply chain management, entering the large-scale manufacturing stage.

This means that competition in the lithium battery industry has entered the second half, where product quality and cost-effectiveness become key points. Extreme cost, efficiency, and yield rates are the common pursuit of the entire industry chain. Digital transformation and smart manufacturing are core ways for enterprises to upgrade production and enhance comprehensive competitiveness.

Currently, digital transformation and smart manufacturing in the industry are transitioning from concepts and goals to specific implementations, gradually penetrating lithium battery factories. Using digital and intelligent technologies as a medium, it helps factories optimize production models, truly achieve 'smart manufacturing,' and achieve extreme cost reduction and efficiency improvement.

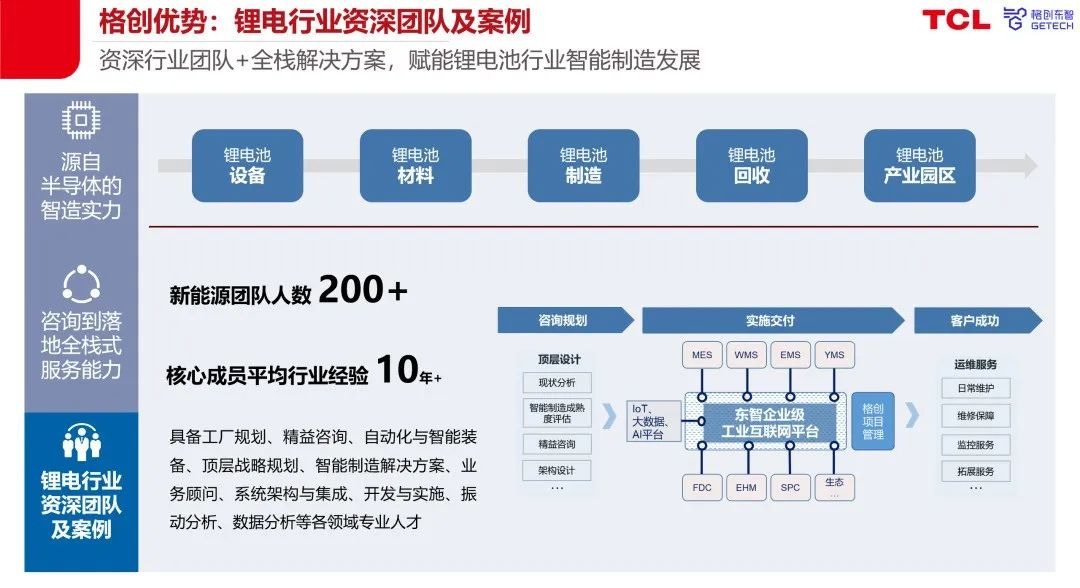

As an industrial internet enterprise strategically incubated by TCL, GETECH strategically deepens its presence in the new energy industry chain, providing new energy enterprises with full-stack smart manufacturing solutions from consulting to delivery. Starting from multiple dimensions such as production, equipment, quality, energy, and logistics, it helps enterprises build benchmark smart factories and is committed to becoming a globally competitive new energy integrated factory digital intelligence expert.

Born from semiconductors

Understands manufacturing better

As a global leading technology industry group, TCL has formed three core industries over 40 years of development: semiconductor display, new energy photovoltaics and semiconductor materials, and smart terminals.

Among them, semiconductor manufacturing processes are complex, highly automated, and fast-paced, with extremely high requirements for efficiency, yield, and cost control. In this context, TCL uses core technologies such as IoT, big data, and AI to nurture advanced smart manufacturing technologies and support capabilities, laying a solid foundation for cross-industry empowerment.

In 2018, GETECH was strategically incubated by TCL with the mission of 'internal support, external output,' forming TCL's internal smart manufacturing achievements into solutions to empower Chinese manufacturing across industries.

In recent years, GETECH has focused on deepening smart manufacturing in the new energy industry chain, targeting lithium batteries and photovoltaics, leveraging the technological and experience advantages accumulated in the semiconductor industry to provide full-chain digital intelligence upgrades for the new energy industry.

The smart manufacturing needs of the lithium battery industry are highly similar to those of the semiconductor industry in terms of extreme quality, equipment stability, and capacity release. 'Our past experience in managing fully automated production systems in semiconductors, the entire CIM system, including底层 automation equipment control and upper-level data applications, can be seamlessly applied to new energy factories with excellent applicability,' said Li Nan, General Manager of GETECH's New Energy Business Group.

The semiconductor background brings not only technology and solutions but also advanced manufacturing concepts and management methods.

Li Nan stated that GETECH's entire set of smart factory construction, operation, and management logic methodology comes from the industrial site, which is one of its core advantages. 'We clearly understand how to help enterprises reduce costs and increase efficiency through business梳理, management optimization, and system construction from a business perspective, truly挖掘 the digital value of industrial sites.'

Additionally, GETECH always adheres to and practices a business-driven, value-focused mindset. According to reports, most business team members in GETECH's New Energy Division come from the lithium battery and photovoltaic industries, with nearly half having backgrounds in process and production. To better understand and match customer business needs, the team is specially equipped with lean consultants and factory planning experts.

GETECH believes that factory smart manufacturing transformation and upgrading have entered a deep stage. Simply approaching from a digital perspective can no longer meet the higher standards of intelligence and integration. Instead, it is necessary to fully挖掘 data value, empower production and operations, and achieve IT and OT integration.

Whole factory empowerment advantage

Driving industry breakthrough

With the continuous improvement of new energy production processes and quality requirements, more manufacturers realize the importance of digital transformation. Lithium battery enterprises' needs have shifted from单一的 MES systems to end-to-end smart factory systems, requiring a complete and stable integrated factory smart manufacturing solution to achieve business goals.

In the exploration of new energy industry intelligent upgrades, due to a lack of overall layout concepts and implementation experience, many enterprises' system constructions suffer from scattered, chaotic, and poor issues. Digitalization is mainly单点-based, lacking overall planning and optimization order, leading to reduced smart manufacturing effectiveness.

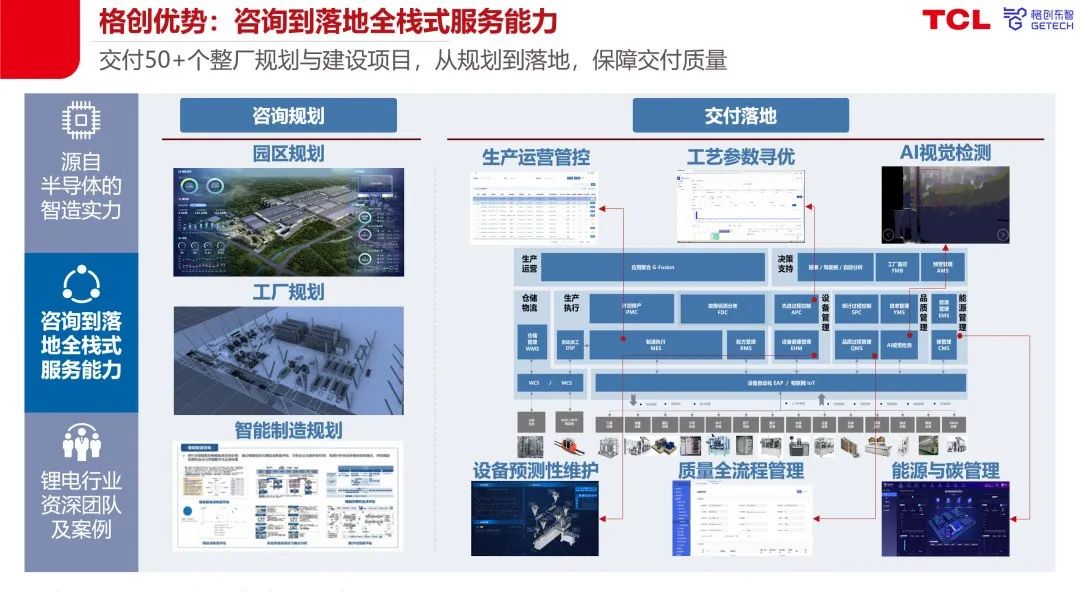

'Rather than simply providing a software system, enterprises need overall solutions, including factory construction consulting and planning, system development and implementation, operation and maintenance, and other services,' Li Nan pointed out. Gechuang has gathered a significant proportion of industry资深 talents from front-line factories with years of whole factory service experience. It excels in providing new energy enterprises with full-cycle, full-chain solutions and services from whole factory consulting and planning to system software implementation, starting from multiple scenarios such as production, equipment, quality, energy, and logistics.

Based on deep industrial know-how and standardized platforms, GETECH proposes a package of smart manufacturing solutions to meet the smart manufacturing needs of the new energy industry. Taking lithium battery factories as an example:

For new factory construction, GETECH proposes a native smart factory solution, 'demanding ramp-up speed from new factories.' GETECH believes that lithium battery smart factory design requires organic integration of factory design, factory planning, and smart manufacturing planning. Factory planning and smart manufacturing planning should be前置 and integrated during the design stage, fully considering comprehensive digital application, and accelerating smart factory落地 based on standardized architecture, so that new factories' operation levels reach a higher standard from the start.

In terms of factory planning前置 and integration, through value stream simulation evaluation and system simulation, build a digital twin system to achieve verification and continuous optimization of factory layout planning.

In terms of smart manufacturing planning前置 and integration,前置 the standards involved in planning, such as equipment interconnection, energy, and business application specifications, provide前瞻 guidance for equipment procurement and factory construction, ensuring rapid smart factory落地.

For old factory intelligent upgrade and transformation, GETECH starts from multiple dimensions such as production, equipment, quality, energy and carbon, and storage, 'demanding high-quality capacity from old factories.'

In production, based on MES, GETECH deeply integrates multiple systems such as equipment automation control, plan management, recipe management, process parameter monitoring, and warning management, ensuring compliant production execution while real-time monitoring and精细化管理 of production processes, truly achieving organic integration of manufacturing systems and production line equipment, and realizing production and process automation.

In equipment, build an integrated equipment management solution, with machines as the core, construct a central-level monitoring, alarm, and control center to achieve工况 process monitoring and machine condition analysis; use work orders as an index to achieve multi-mode equipment intelligent maintenance and operation such as TPM (total productive maintenance), TBM (time-based maintenance), CBM (condition-based maintenance), PHM (predictive health management), ensuring efficient and stable equipment operation.

In quality, create a 360° quality management system, standardize whole-process control, integrate yield management; based on data-driven quality analysis and optimization, use multi-factor analysis for abnormal root cause定位, quality prediction, and parameter tuning; based on AI vision for automatic defect detection and classification; achieve closed-loop control from异常 occurrence, analysis to resolution, helping process and quality optimization.

In energy and carbon, from three dimensions: energy management, carbon management, and AI-driven energy saving and carbon reduction, help lithium battery enterprises achieve global energy monitoring and management, enterprise carbon management, energy-saving optimization control, and energy-carbon linkage; Gechuang's products are certified by SGS, an international first-line certification机构, and can directly provide lithium battery enterprises with carbon emission accounting reports that meet international standards, helping enterprises, especially those going global, reasonably plan future lithium battery carbon footprints and supply chain green emission reduction optimization.

In storage and logistics, besides helping lithium battery enterprises with digital storage management through warehouse management systems, also provide intelligent logistics planning, combined with intelligent equipment and automation transformation to achieve intelligent management of lithium battery立体库/flat库 and automated logistics.

Diversified solutions

Covering the entire industry chain

In the second half of new energy, many enterprises focus on R&D innovation, cost reduction and efficiency improvement, supply chain expansion, and ESG to strengthen internal capabilities, cope with changes, and elevate digitalization and intelligence to a higher position.

Currently, GETECH's service scope covers the entire new energy industry chain upstream and downstream, providing different smart manufacturing solutions for lithium battery materials, equipment, battery manufacturing and recycling, as well as photovoltaic cells, components, and power plants. It has created industry benchmark cases including弗迪电池,蜂巢能源,金羽新能,格林美,瑞翔新材, helping the new energy industry achieve intelligent and green sustainable development.

At弗迪电池 and蜂巢能源, GETECH built smart energy and carbon management brains for the enterprises, achieving unified, complete, and compliant management of energy and carbon data, implementing multi-plant digital energy management and carbon management applications, helping enhance ESG management capabilities.

At金羽新能, GETECH created a lithium metal battery mass production line production operation management system, with manufacturing as the core, connecting计划, storage, process, quality, equipment, and other links, achieving精细化管理 of production management, real-time production control, and transparent production processes, driving lean production operation管控 with data.

Accelerating global layout

Winning in the new era of going global

In supporting global enterprise manufacturing布局, GETECH has developed technical service capabilities for international clients.

For example, GETECH provided one-stop smart operation and maintenance services for a North Macedonian factory, achieving comprehensive monitoring, analysis, and management of operation data; using a Zhejiang factory as a pilot, it built an equipment health management system that significantly improved equipment operation efficiency and reduced failure losses, and推广 to overseas factories in France and Germany; at an Indian factory, GETECH significantly improved production管控 efficiency through the construction and deployment of production manufacturing systems.

Currently, in the global new energy smart manufacturing service field, apart from foreign giants like Siemens, Dassault, and SAP, there are no large-scale, comprehensive manufacturers with integrated capabilities, and the industry格局 is not yet settled. Relying on the升维 advantages from its semiconductor background, GETECH has grown into a globally competitive new energy integrated factory digital intelligence expert, driving industry digital empowerment breakthroughs.

On one hand, GETECH has沉淀 standards for new energy industry smart factory construction, including lean manufacturing and process standardization, automation and equipment architecture standardization, and IT architecture standardization, enabling rapid replication and推广 of overseas factories.

On the other hand, GETECH has a global talent and expert顾问 team with rich experience in overseas project development and implementation, familiar with overseas market policies, deeply understanding factory digital transformation needs, able to maintain close and effective communication with regulatory agencies and partners, providing tailored localized solutions for enterprises.同时, GETECH provides overseas驻点 localized services, bringing localized and精细化的 operation support to overseas factories.

In the future, facing the broad development space of new energy industry digitalization, GETECH will continue to deepen and further penetrate, contributing digital intelligence力量 in the journey of new energy industry upgrade and transformation.