Practical Guide! The Right Way to Select Equipment Digitalization Platform

How to choose a suitable equipment management system or a digital platform for integrated equipment engineering management is an important decision that enterprises often face. System selection requires comprehensive consideration from multiple dimensions, including the system's business adaptability, maturity and stability, later scalability, as well as the partner's advisory implementation service capabilities and industry cases. Based on years of industry experience, the author has summarized some selection suggestions for many enterprises' system choices for reference.

Choose self-development or mature products?

When selecting an equipment digitalization platform, a primary issue is to decide whether to develop in-house or purchase mature products on the market. This is usually a key consideration for the enterprise's IT head or CIO. To demonstrate the value of their department, CIOs in enterprises with more IT staff often recommend investing in self-development for autonomy and control.

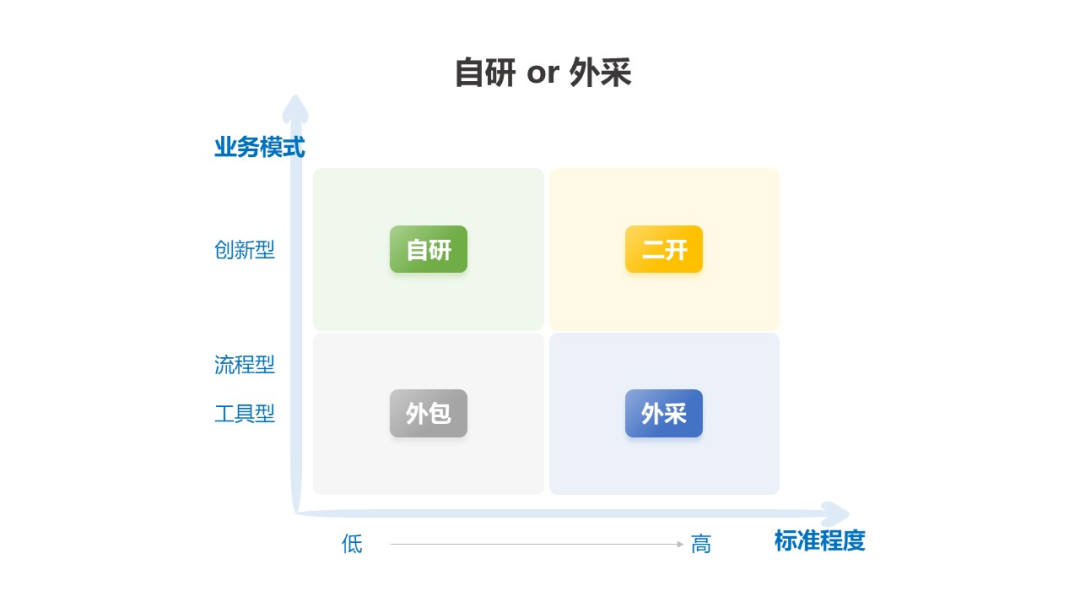

A simple way to judge whether a software system needs self-development is to consider two dimensions: whether it is an innovative business model and the maturity of market standards, as shown in the figure below:

Figure: Dimensions for measuring self-development or external procurement

By applying equipment management software to the above figure, we can see: from a business model perspective, equipment management software is process-oriented and typically does not involve the enterprise's core product processes or key know-how. Additionally, from the perspective of market standardization, equipment management software is relatively universal, and market standards can be relatively high. Therefore, overall, equipment digitalization platform selection is more suitable for choosing mature product applications.

Although self-developed software may have uniqueness and personalization, it may involve reinventing the wheel, with business departments facing risks of pitfalls and high costs.

In the current investment environment, enterprise IT should focus its efforts on core competencies or digitalization of innovative business models, such as process optimization algorithms for specific production scenarios. The equipment management software market is highly standardized; for this area, the author recommends choosing market-mature software systems that have been validated by the market and leading customers, with friendly secondary development and interfaces.

Professional industrial software OR lightweight low-code products?

After deciding to choose mature products for further selection, enterprises may face two major camps in the market: one is professional equipment industrial software, and the other is lightweight systems built by IT technology vendors through technology platforms, low-code platforms, etc.

Some lightweight low-code products are built on low-code platforms, with advantages such as low cost, relatively easy development, deployment, and maintenance, but disadvantages like poor interactive experience, making them suitable for small and medium-sized enterprises (SMEs) with relatively simple needs, clear goals, and only requiring electronic management of paper processes. The advantage of these products is that they can quickly meet basic paperless needs, providing low-cost solutions for SMEs.

However, for medium and large enterprises, more careful weighing is needed. Although lightweight low-code products have controlled costs, they have certain limitations in key areas such as deep user experience, professional functions like equipment data monitoring and real-time analysis, and implementation services. This may hinder medium and large enterprises from fully realizing their potential, especially in later high-level application stages when equipment management tasks require complex monitoring and control optimization scenarios based on equipment status and machine parameters.

Therefore, it is recommended that medium and large enterprises choose more professional equipment management software. On one hand, these software offer a richer set of functions to meet complex needs, including equipment status monitoring, health analysis, predictive maintenance, performance process analysis, etc. On the other hand, they usually provide more professional implementation services and support to ensure the success of digital transformation. For medium and large enterprises, this is undoubtedly a wise investment. It can improve equipment operational efficiency, reduce maintenance costs, enhance process capability and yield levels, and strengthen manufacturing competitiveness.

Choose a system with low-code secondary development and configuration capabilities

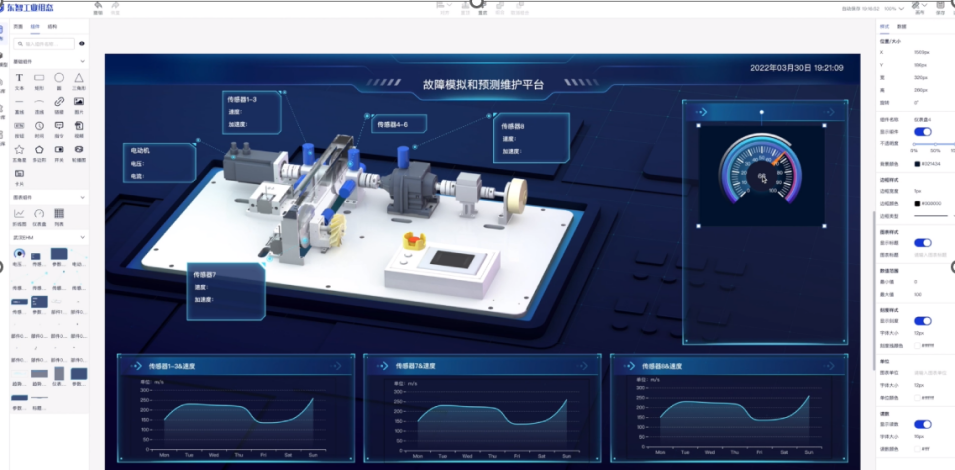

As business continuously evolves, elements such as management processes, visual dashboards, and analytical reports often need adjustments and improvements based on new requirements. At this time, systems with low-code secondary configuration capabilities become very valuable.

Low-code development environments allow users to perform visual development without deep programming knowledge, enabling custom configuration of the system. This allows enterprises to flexibly modify and extend system functions according to actual needs, without long development cycles and high development costs. Professional software systems combined with low-code secondary development capabilities allow enterprises to independently adjust the system to adapt to rapidly changing needs.

This feature is particularly important for enterprises that need to continuously optimize and expand their digital systems.

Figure: Low-code configuration monitoring screen

Choose a platform product with integrated equipment engineering management capabilities, especially equipment data analysis capabilities

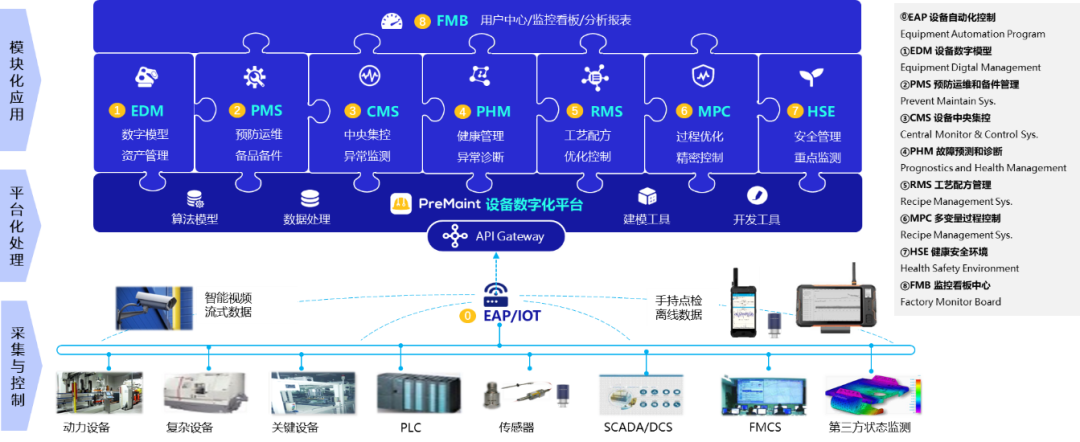

The field of equipment management is moving towards integrated equipment engineering management. This integration includes combining all stages of the equipment lifecycle, such as planning, procurement, deployment, monitoring, maintenance, and disposal, as well as essential full-element assets for intelligent equipment, including hardware, software, data, models, etc. Particularly, soft assets like equipment data and models are core asset elements for enterprises. This integrated management approach enables enterprises to manage their equipment assets more comprehensively, coordinated, and efficiently.

Figure: Management objects for full elements and full cycle of new industrial equipment

Choosing a platform product with integrated equipment engineering management capabilities can integrate information from all links into a unified system, making equipment management more seamless. Starting from equipment procurement and planning, equipment data and maintenance needs can be considered in advance, allowing for early planning of maintenance strategies and reducing future maintenance costs.

Especially in equipment data analysis, an integrated platform can provide broader data collection, analysis, and visualization tools to support predictive maintenance and performance optimization. This means enterprises can better utilize equipment data, identify issues timely, and take measures to reduce downtime and improve equipment availability.

Figure: Integrated equipment engineering platform

Choose a service team with business advisory capabilities

When selecting an equipment digitalization platform, we are not just choosing a system platform but more importantly, a partner team that can provide professional guidance and assist enterprises in upgrading processes, management, and data. The value and industry experience of team advisors far exceed the value of mere system functions.

Business advisory services play a crucial role in digital transformation. They can deeply collaborate with enterprises, understand their unique needs and challenges, and provide tailored solutions. This includes work in key areas such as process optimization, management practice improvements, and data upgrades.

Business advisory services not only provide valuable professional experience but also offer strategic insights. Their goal is to help enterprises better respond to market changes, improve operational efficiency, reduce costs, and ensure maximum utilization of digital systems.

Additionally, business advisory services can provide training and guidance to ensure that the enterprise's team can fully utilize the system's functions. This support helps enterprises better cope with the challenges of digital transformation, ensuring successful project implementation and long-term success.

Recommended equipment digital management platforms

Based on years of industry experience, we recommend two platform products with secondary configuration capabilities:

◉ Maximo: Maximo is a product from IBM, focused on asset management, widely used globally with 30 years of practical experience. Maximo primarily centers on asset management and work order management, including equipment management, work order management, preventive maintenance, resource management, etc., as well as optional workflow management and decision analysis functions, supporting integrated condition monitoring and predictive maintenance. Maximo's strength lies in its workflow and business process configuration functions, enabling users to easily perform system authorization management and custom improvements, widely applicable to various large group enterprises. It has多次入围Gartner's EAM leader quadrant.

◉ PreMaint: PreMaint is an integrated equipment engineering management platform based on industrial internet launched by GTRONTEC, successfully applied in over a hundred customers across more than ten different industries domestically. As the name suggests, besides basic equipment information management and process management, it focuses more on predictive maintenance and advanced analysis. PreMaint's advantage is that it can meet enterprises' needs to build integrated equipment data application systems, real-time perceive equipment operating conditions and process health status, and achieve functional closed loops from monitoring to预警, fault diagnosis, maintenance handling, and process automatic optimization. It can meet complete equipment engineering management needs. For SMEs, a lightweight SaaS version product has been launched for quick deployment.

When selecting an equipment digitalization platform, enterprises should base it on their own needs, industry characteristics, and scale to ensure correct selection, smooth implementation, and ultimately achieve improved production efficiency and cost control. This is not only a technical and investment decision but also a key decision affecting the enterprise's future competitiveness.