Zero Carbon Era, Lithium Battery Entire Chain Explores Energy-Saving and Carbon Reduction Solutions

Strengthening carbon management and achieving carbon reduction or even zero carbon has become an important dimension for the high-quality development of lithium battery enterprises.

According to relevant calculations, current power battery production carbon emissions account for about 20% of the total lifecycle emissions of pure electric passenger vehicles. Battery production involves high-energy-consuming processes such as mining, smelting, and chemical engineering. With the arrival of new development cycles domestically and internationally and the implementation of related policies, the power battery industry is also facing new carbon reduction responsibilities.

On one hand, facing an increasingly fierce domestic market environment, cost reduction and efficiency improvement have become urgent needs in the industry. This poses great challenges to low energy consumption, low emission management, and the resulting cost control in the battery production process.

On the other hand, international regulations on battery production carbon emissions are becoming stricter. On August 17, 2023, the EU Battery and Waste Battery Regulation officially came into effect and will apply from February 18, 2024. The new regulation requires battery exporters to disclose carbon emission data from upstream minerals, materials to battery production, recycling, and reuse. It mandates that batteries must have a clear and indelible carbon footprint declaration and label, reporting carbon footprint, carbon footprint share at each lifecycle stage, carbon footprint performance level, etc. Existing domestic lithium battery industry enterprises have significant shortcomings and room for improvement in multiple areas, from production to carbon footprint tracing, and even waste battery recycling and utilization. Various types of enterprises in the lithium battery industry chain face unprecedented low-carbon and carbon reduction challenges. With expanding into Europe and America becoming an important development strategy for battery enterprises, establishing a full lifecycle carbon reduction and zero-carbon system is the key to gaining a competitive advantage in the international market.

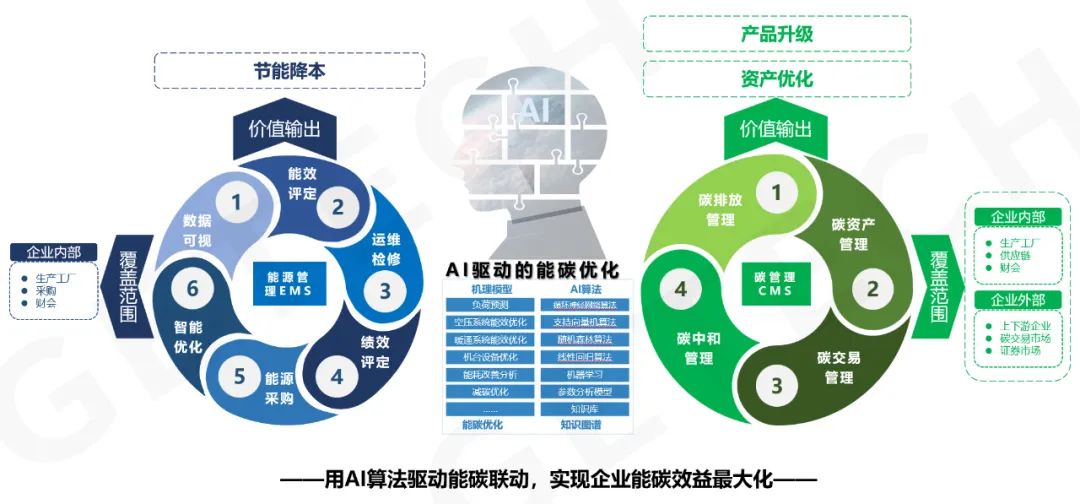

Based on this, as a globally competitive new energy whole-plant digitalization expert, GTRONTEC has launched a multi-scenario integrated smart energy and carbon management solution, building energy and carbon management systems and capabilities for the entire enterprise lifecycle, using digitalization and intelligence to help lithium battery enterprises achieve low-carbon and sustainable production, empowering the transformation and upgrading of the new energy industry.

Energy and carbon management is not just about implementing a system

Currently, the carbon emission crisis faced by lithium battery enterprises is not individual but industry-wide. Lithium battery enterprises are being forced to implement energy and carbon management throughout the entire supply chain. Therefore, doing well in energy and carbon management, product carbon emissions and accounting, origin tracing, etc., and controlling carbon cost is particularly important for enhancing corporate market competitiveness.

GTRONTEC believes that energy and carbon management is not just about building fragmented systems and promoting them in phases. More importantly, it requires overall planning, advancing management and technological changes from internal production to external supply chains. At the same time, gathering forces from the entire industry chain to maximize the value of dual-carbon business and improve the international competitiveness of the domestic lithium battery industry. Only by enhancing the overall low-carbon manufacturing capability of the industry can we break the stereotype of resource waste in Chinese manufacturing and overcome overseas carbon封锁 (carbon blockade).

Energy and carbon management should be a systematic construction. For example, energy management should cover scenarios such as energy visualization, energy efficiency assessment, maintenance, performance management, energy procurement, and intelligent optimization, forming a complete and sustainable PDCA energy management system value closed loop. Carbon management should cover four types of scenarios: emission management, asset management, transaction management, and reduction management. Enterprises should use energy management and carbon management as two key levers to form an innovative carbon-neutral digital management closed-loop model from energy saving and carbon reduction to low carbon, zero carbon, and sustainable development.

Specifically, the enterprise digital energy and carbon management system can be built in three steps:

First, lay the foundation to ensure source data quality. Currently, the lithium battery industry is in a state of large-scale expansion, with common issues in energy and carbon management such as insufficient management awareness, lack of senior attention, unreasonable personnel allocation, incomplete basic measurement systems, and不规范 (non-standard) management system construction.

GTRONTEC believes that improving infrastructure and data foundation is a basic condition for energy and carbon management. If the measurement system is uneven and the measurement granularity is coarse, data integration and business relevance are weak, it will cause difficulties in monitoring key indicators and make it hard to analyze data such as energy consumption per watt-hour combined with production processes and output.

To address these issues, enterprises should build efficient measurement systems and collection standards based on the characteristics and processes of the lithium battery industry, construct multi-dimensional models, and form standardized rule libraries and response measures. At the same time, build IoT, data connectivity, and intelligence capabilities to achieve integrated management of energy and carbon data access, storage, calculation, modeling, visualization, analysis, and archiving, laying a data foundation for data and business integration.

Second, identify problems and implement energy saving and consumption reduction. In lithium battery production, there are multiple key energy consumption points, including public auxiliary side large power facilities such as air conditioning and chiller systems, air compression systems, and production side positive and negative electrode material production, electrode coating drying, and drying unit operation in production干燥间 (drying rooms), which pose great challenges to enterprise energy and cost control.

Taking the negative electrode material graphitization process as an example, electricity costs account for 60% of its cost. The process energy consumption of mainstream坩埚炉 (crucible furnaces) is as high as 11,000 to 15,000 kWh per ton. Most enterprises with 10,000 tons of graphitization capacity have electricity consumption of over 120 million kWh. A 10% increase in electricity costs leads to a 6% increase in graphitization costs.

High energy consumption not only brings huge cost pressure to lithium battery enterprises but also directly affects production stability. Research data shows that in some regions strictly controlling high-energy-consuming industries, graphitization capacity has decreased by 40%, with头部 (leading) negative electrode enterprises affected by 10% to 20%, and small and medium enterprises even shutting down due to power restrictions.

In the past, in energy consumption management, enterprises typically implemented business applications through self-control systems, power SCADA systems, DCS systems, etc., at the software level, which had high costs and poor flexibility, unable to meet diverse dynamic management needs, and artificially created silos between various applications. At the hardware level, there was a tendency to simply do energy-saving technical renovations by introducing new hardware or technologies to improve energy efficiency but ignoring actual usage scenarios, such as大马拉小车 (using a big horse to pull a small cart). The root cause of these phenomena is focusing only on equipment while neglecting on-site usage methods, demand matching, and system operation chain reactions.

To address these issues, GTRONTEC believes that on one hand, an intelligent management application covering the entire enterprise lifecycle and all energy and carbon emission scenarios should be built, including energy management, carbon management, AI analysis and control, and other scenarios, integrating dozens of functional modules to打通 (connect) the enterprise's energy flow, information flow, and value flow.

On the other hand, through consulting and diagnosis, analyze the current status of energy use and management in lithium battery enterprises, efficiently plan energy-saving schemes, and select energy-saving measures. Systematic optimal energy consumption indicators should be established, such as for overall energy consumption, chillers and air compressors, coating machines, etc., and optimized based on actual operating scenarios, production models, and energy consumption models. At the same time, build intelligent AI + energy-saving renovation linkage schemes, use edge computing, big data, and other technologies to构建 (build) a cloud-edge-end integrated prediction, optimization, and control closed loop, establish multi-parameter multi-objective optimization models and control strategy execution, covering power distribution, HVAC, air compression, key energy-consuming equipment, and build the optimal energy consumption model for enterprise equipment objects to achieve intelligent management of energy visibility, knowability, and controllability.

Third, empower low carbon and zero carbon. Currently, some domestic lithium battery manufacturers such as CATL, Envision AESC, and SVOLT have started carbon reduction strategies and are actively exploring carbon-neutral paths for power battery production.

The concept of carbon management in the lithium battery industry can be broad or narrow. Macroscopically, it is a systematic project; microscopically, from raw material procurement to production and shipment, it involves层层嵌套 (layered nesting) and interconnection of several related scenario units. In the current process of promoting low-carbon production management, supply chain carbon emission data network collaboration, carbon consulting service extension, and other new digital models of carbon management, there are often one-sided understandings, easily interpreting overall carbon management system construction with isolated carbon data collection and carbon inventory report application scenarios, lacking consistent understanding and goals.

Similar to energy management, digitalization is also an important means for lithium battery enterprises to reduce carbon costs.

GTRONTEC believes that based on the industry characteristics of lithium batteries, starting from the energy use structure, through expert consulting and digital application combination, help lithium battery enterprises achieve product carbon footprint construction. Based on multiple industrial digital practices in the new energy industry, GTRONTEC proposes that the multi-dimensional construction of carbon management application scenarios for lithium battery enterprises is the skeleton of systematic carbon management, but赋予其灵魂 (giving it soul) requires the closed-loop贯通 (integration) of overall data.

Traditional Chinese medicine says通则不痛,痛则不通 (free flow prevents pain, pain indicates blockage). The organic operation of the carbon management digital intelligence body in lithium battery factories similarly requires building capillaries and nerve endings, main arteries and neural networks that support efficient data flow, achieving the循环流动 (circulatory flow) of data in carbon management digital scenarios. Therefore, establishing systematic carbon management for lithium battery enterprises and building a digital system is only setting up a输血平台 (blood transfusion platform); the real complexity is how to低感知 (low-perception) embed this blood transfusion platform into the constantly operating enterprise body and connect all links.

Through the linkage of energy management and carbon management, energy saving and carbon reduction based on data is also a key思路 (idea) for GTRONTEC to implement the dual-drive strategy of carbon management and energy management. One of GTRONTEC's key products, the CMS enterprise carbon management system, can help enterprises establish a full-process carbon measurement system, implement carbon footprint tracking, achieve carbon emission calculation, carbon inventory reporting, product carbon footprint, carbon reduction management, carbon asset management, and other functions. It connects with certification bodies like SGS to achieve carbon certification, and the output audit reports can support direct certification applications, reducing user verification costs by 30%-50%. Combined with AI algorithms, it can effectively achieve carbon emission quantification, analysis, management, and reporting, targeting碳成本 (carbon cost) related challenges.

GTRONTEC's CMS carbon management system has accumulated relatively rich solutions and customer experience in the lithium battery industry. Based on the process characteristics of the lithium battery industry, it customizes and standardizes databases, builds efficient measurement systems, and lays the foundation for data and business integration. It also builds industry industrial dual-carbon management models, integrates multiple technology stacks such as mechanisms and algorithms, with high data model mechanism and industrial know-how content, empowering lithium battery enterprises to achieve dual-carbon goals and helping them build green and intelligent benchmark factories.

As one of the few domestic digital providers offering one-stop solutions from carbon tracking, carbon measurement, carbon management to carbon neutrality, GTRONTEC has a rich product matrix and manufacturing dual-carbon digital implementation experience in the dual-carbon field, continuously refining and launching core products such as energy management EMS, carbon management CMS, and environmental health management EHS, which can help lithium battery enterprises achieve energy saving and carbon reduction, low carbon, zero carbon, and sustainable development.