Data Intelligence, Empowering Full-Process Management and Optimization of Lithium Battery Production Quality

2023-11-29

In recent years, with the rapid development of the global new energy market, the lithium battery industry is in a stage of rapid development. Under the background of "carbon neutrality", with high energy and environmental protection, lithium batteries have become the most important energy storage components. Especially benefiting from the strong growth of the new energy vehicle market, the demand for lithium batteries has exploded, driving the development of lithium battery enterprises.But at the same time, with the rapid development of the industry, safety issues such as lithium battery fires, explosions, and leaks have also made terminal businesses increasingly demanding higher quality, safety, and consistency of lithium batteries. From past PPM requirements to current PPB exploration, from 3σ, 7.5σ to 9σ evolution, lithium battery enterprises are committed to continuously seeking better solutions under higher quality pursuits to maintain market competitiveness.

Lithium Battery Production Process is ComplexHow Difficult is Quality ControlLithium battery production process is complex, and fluctuations in the quality control level of each process can have a significant impact on the final product quality. In each link of the core production process, defects are easily caused by factors such as the quality level of key components like conductive agents, positive and negative active materials, environmental temperature and humidity, and operator skill. For example, coating may result in head thick, tail thin, thick edge, exposed foil, unstable surface density, etc.; rolling electrodes may have uneven winding, wrinkled edges, thickness rebound, unstable thickness, etc...How to control the quality of each link, detect abnormalities early and complete handling, achieve PPM to PPB level quality, is the main focus for lithium battery enterprises to improve product quality. When moving towards high quality and high consistency goals, the lithium battery industry generally faces the following difficulties that need to be突破ed: 1. Process quality has not formed an effective monitoring and management closed loop, abnormal handling is not timely, efficiency is low1. Accurate quality inspection is one of the key means of quality control. But currently, many processes of cells still rely on manual visual inspection, for example, V-angle burr detection in cutting and stacking relies on manual periodic sampling, leading to burr abnormalities not being detected and removed in time, ultimately causing up to 1% yield loss. Moreover, it is unable to obtain large sample细分 quality data, making it difficult to support subsequent effective analysis and improvement;2. Process inspection data such as first inspection and patrol inspection rely on manual work order records, for example, changeover first inspection and environmental dust detection are all manually recorded on paper and then consolidated into Excel, data timeliness is low, and it cannot be managed effectively in time;3. Key process parameters lack effective monitoring means, only through simple threshold control by equipment and on-site notification, it is difficult to effectively identify and handle abnormalities, ensuring product consistency;4. Process quality abnormality problems lack systematic management. For example, after quality problems occur, tracing back to previous processes and responsibility attribution rely on communication groups or paper sign-off circulation, from quality problem occurrence, review,定位, improvement, effect tracking to knowledge沉淀, most are offline作业 management, process is missing.2. Quality abnormality定位 relies on manual experience analysis, QCC activities, and cell disassembly experiments, making it difficult to efficiently confirm the root cause of abnormalities1. Quality abnormality定位 often requires跨 multiple processes, involving large amounts of data, and the traceability identifiers of极卷 and极芯 are inconsistent, data matching processing is difficult, relying on manual experience定位, manual analysis efficiency is low;2. Generally, enterprises will sample a certain proportion of abnormalities for cell disassembly experiments to locate problems, which often takes a long time, abnormalities are difficult to intercept and improve in time;3. For major quality problems that are difficult to improve for a long time, enterprises generally use QCC activities to brainstorm列出 core abnormality-related influencing factors and combine experimental verification to eliminate them one by one, the cycle is long, and improvement effects easily encounter bottlenecks.3. Control optimization relies on manual experience, equipment parameter collection, analysis, and adjustment are disconnected, no effective automatic management process is formed, real-time process correction is difficult1. Many processes such as coating and winding have numerous related parameters, which may be affected by previous processes, requiring continuous parameter adjustment until the process reaches the optimal state. However, parameter adjustment relies on manual experience, parameter adjustment strategies vary from person to person, lack standardization, making it difficult to沉淀 engineering experience and ensure optimal parameter adjustment strategies, quality control lacks guarantee, easily causing waste;2. Parameter adjustment results require a certain waiting time to verify the effect, and parameter adjustment often requires multiple trial adjustments, adjustment efficiency is low, easily causing product waste;3. During production line changeover, parameter adjustment lacks抓手, full production调试 takes 4-6 months, capacity loss is large. Improve Quality with "Intelligence"Solve Production Quality Control ChallengesFor the above common pain points in lithium battery production quality, GETECH Eastwise, based on data intelligence and applications, launches a lithium battery quality full-process management and optimization solution, through 360-degree quality management applications, achieve full-process digital quality management, to achieve ultimate yield:Key Method 1: Based on potential failure mode analysis, identify key control points and perform full data real-time collection, achieve full-chain data integration of quality processesAiming at the high quality and high consistency requirements of lithium battery production, combined with failure modes, analyze key control points of the production process from the 4M1E dimension, and perform data collection, and based on this, form a rich database, laying the foundation for subsequent data analysis, for example:1. Process quality inspection indicators: Based on visual inspection and AI fusion technology, replace the work of relying on manual visual inspection for defect judgment and classification. For example, V-angle burr detection in cutting and stacking, sealing pin welding, vertex welding and other appearance defects, accurately identify and judge defect types, autonomously decide defect handling methods (rework, scrap, release);2. Environmental indicators: Environmental dust, temperature and humidity have a great impact on lithium battery quality, therefore, by installing露点仪 to real-time detect environmental temperature and humidity, dust data, and based on IoT technology to achieve data collection;3. IPQC inspection data: Adopt electronic recording mode, use electronic inspection templates, through PDA and other mobile terminals to achieve electronic data recording, replacing the past paper recording mode, so that key material information such as positive and negative materials, separators, electrolytes can be fully recorded, process first inspection, patrol inspection data can also be recorded in time to reflect problems;4. Equipment parameters - based on IoT or EAP and other technologies to achieve equipment key parameter collection and recording: Based on the comprehensive collection of the above types of data, supported by a big data platform base, associate lithium battery product production履历 data, inspection data, change time, material data, Marking, etc. through cell code, bare cell code,极卷 code, slurry batch, etc., so that full lifecycle data can be queried through product ID, quality personnel can quickly query and locate abnormalities.Key Method 2: Combine big data technology and process control to achieve integrated quality defect control process of real-time monitoring and预警, analysis, and rectificationAbnormal monitoring and预警: For process inspection indicators (such as surface density), equipment parameters, environmental parameters, material data, and process capability indicators, based on SPC control rules and algorithm models, perform real-time monitoring and预警,及时发现 abnormalities or unstable fluctuations, and notify relevant personnel to take corresponding measures to avoid loss expansion or提前减免 loss. For example, stable parameter control of coating filter pressure difference, oven各区域 temperature zones,各区域 slit gaps, etc.;Abnormal analysis: Based on big data analysis models, when abnormal alarms/预警 occur, synchronously send abnormal analysis reports and abnormal status information to relevant personnel, assisting them in taking optimal rectification measures or联动 equipment for automatic optimization adjustment. For example, in a certain case, after a certain winding machine had a certain proportion of short circuit abnormalities, analysis concluded that it was caused by separator quality issues, timely联动 MES to lock the separator batch for verification and re-inspection, reducing loss;Closed-loop management: For the entire process from abnormality occurrence to closure, record and track through digital processes, each key node needs to be further confirmed by management personnel. When the problem is closed, it can confirm自动升级 quality control standards, form corresponding standard document records, and update the quality control database.

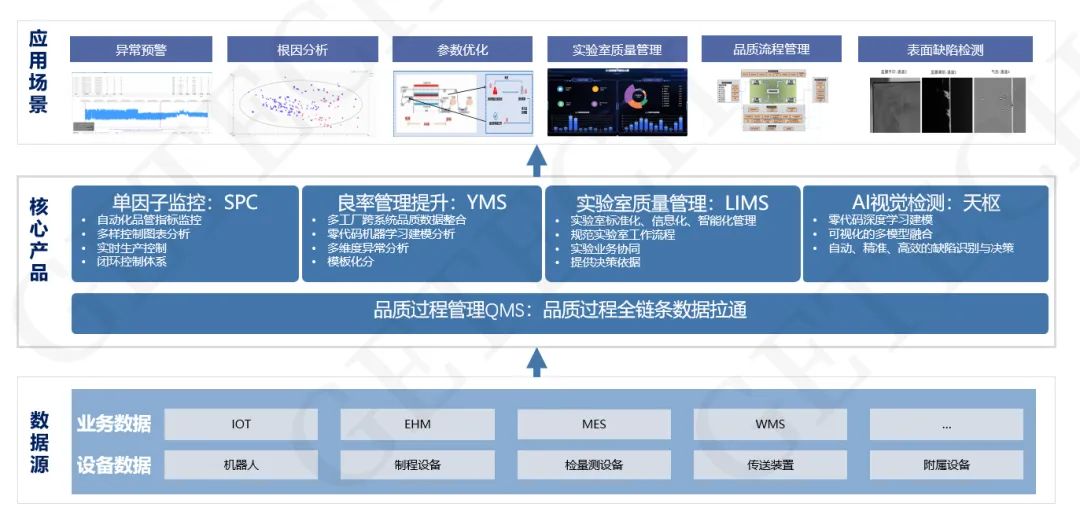

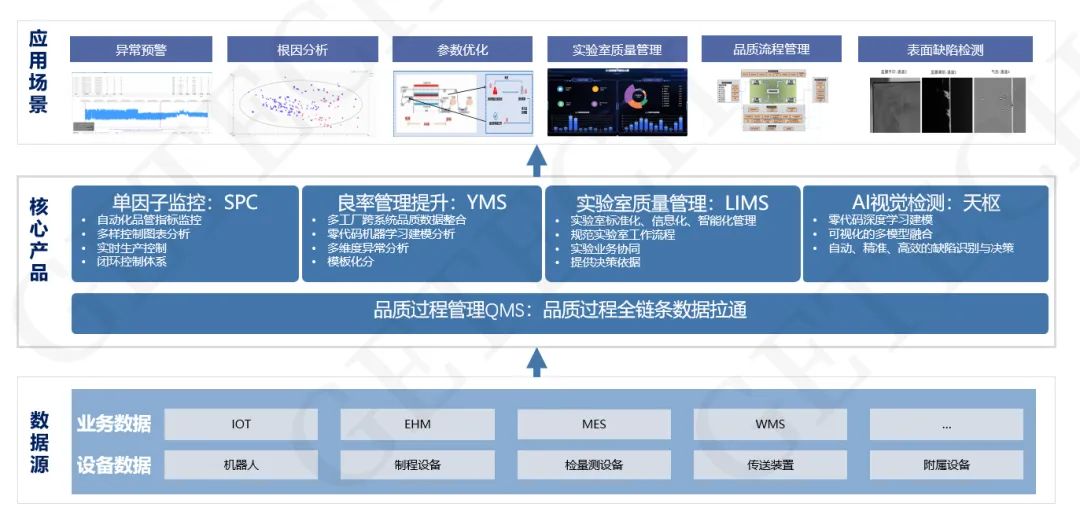

Improve Quality with "Intelligence"Solve Production Quality Control ChallengesFor the above common pain points in lithium battery production quality, GETECH Eastwise, based on data intelligence and applications, launches a lithium battery quality full-process management and optimization solution, through 360-degree quality management applications, achieve full-process digital quality management, to achieve ultimate yield:Key Method 1: Based on potential failure mode analysis, identify key control points and perform full data real-time collection, achieve full-chain data integration of quality processesAiming at the high quality and high consistency requirements of lithium battery production, combined with failure modes, analyze key control points of the production process from the 4M1E dimension, and perform data collection, and based on this, form a rich database, laying the foundation for subsequent data analysis, for example:1. Process quality inspection indicators: Based on visual inspection and AI fusion technology, replace the work of relying on manual visual inspection for defect judgment and classification. For example, V-angle burr detection in cutting and stacking, sealing pin welding, vertex welding and other appearance defects, accurately identify and judge defect types, autonomously decide defect handling methods (rework, scrap, release);2. Environmental indicators: Environmental dust, temperature and humidity have a great impact on lithium battery quality, therefore, by installing露点仪 to real-time detect environmental temperature and humidity, dust data, and based on IoT technology to achieve data collection;3. IPQC inspection data: Adopt electronic recording mode, use electronic inspection templates, through PDA and other mobile terminals to achieve electronic data recording, replacing the past paper recording mode, so that key material information such as positive and negative materials, separators, electrolytes can be fully recorded, process first inspection, patrol inspection data can also be recorded in time to reflect problems;4. Equipment parameters - based on IoT or EAP and other technologies to achieve equipment key parameter collection and recording: Based on the comprehensive collection of the above types of data, supported by a big data platform base, associate lithium battery product production履历 data, inspection data, change time, material data, Marking, etc. through cell code, bare cell code,极卷 code, slurry batch, etc., so that full lifecycle data can be queried through product ID, quality personnel can quickly query and locate abnormalities.Key Method 2: Combine big data technology and process control to achieve integrated quality defect control process of real-time monitoring and预警, analysis, and rectificationAbnormal monitoring and预警: For process inspection indicators (such as surface density), equipment parameters, environmental parameters, material data, and process capability indicators, based on SPC control rules and algorithm models, perform real-time monitoring and预警,及时发现 abnormalities or unstable fluctuations, and notify relevant personnel to take corresponding measures to avoid loss expansion or提前减免 loss. For example, stable parameter control of coating filter pressure difference, oven各区域 temperature zones,各区域 slit gaps, etc.;Abnormal analysis: Based on big data analysis models, when abnormal alarms/预警 occur, synchronously send abnormal analysis reports and abnormal status information to relevant personnel, assisting them in taking optimal rectification measures or联动 equipment for automatic optimization adjustment. For example, in a certain case, after a certain winding machine had a certain proportion of short circuit abnormalities, analysis concluded that it was caused by separator quality issues, timely联动 MES to lock the separator batch for verification and re-inspection, reducing loss;Closed-loop management: For the entire process from abnormality occurrence to closure, record and track through digital processes, each key node needs to be further confirmed by management personnel. When the problem is closed, it can confirm自动升级 quality control standards, form corresponding standard document records, and update the quality control database. Key Method 3: Based on big data analysis technology, build a quality analysis and optimization system to support efficient yield management throughout the production processAbnormal root cause analysis: Based on the daily analysis content of engineering personnel, summarize from overall to equipment yield monitoring analysis, surface density and thickness characteristic values/Defect analysis to 4M1E change analysis to form analysis templates, assist engineering personnel in efficient analysis, quickly grasp the current quality status and take corresponding management measures to improve;

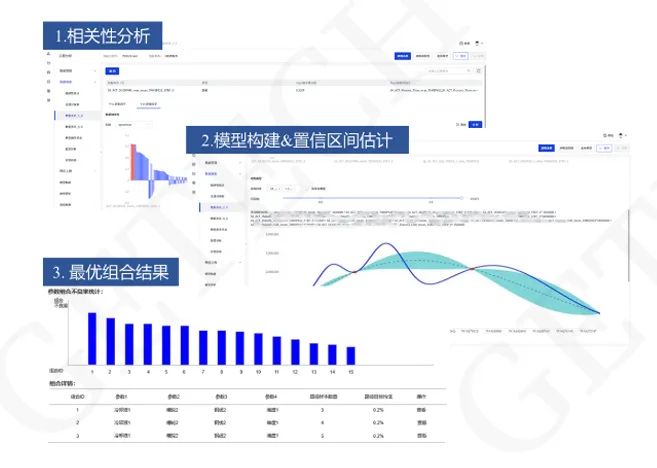

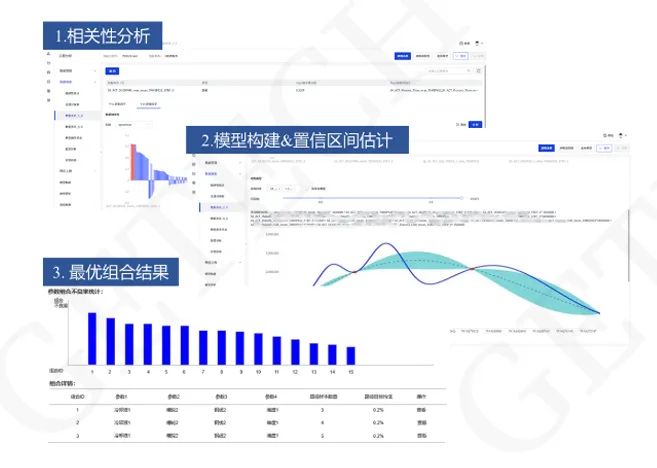

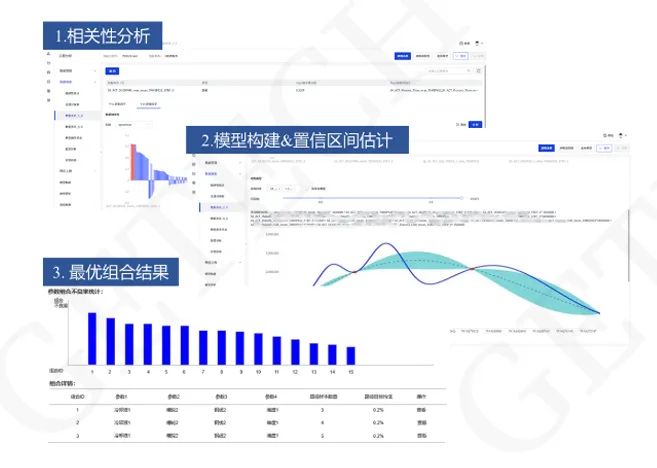

Key Method 3: Based on big data analysis technology, build a quality analysis and optimization system to support efficient yield management throughout the production processAbnormal root cause analysis: Based on the daily analysis content of engineering personnel, summarize from overall to equipment yield monitoring analysis, surface density and thickness characteristic values/Defect analysis to 4M1E change analysis to form analysis templates, assist engineering personnel in efficient analysis, quickly grasp the current quality status and take corresponding management measures to improve;

Usage example: Coating surface density abnormal analysis

Quality abnormality interception: Based on big data algorithm analysis, comprehensively analyze factors from the 4M1E dimension, whether for single process or跨 process quality problem investigation and root cause定位, it can be accurate and efficient. All analysis processes can form knowledge沉淀 and be shared with other personnel. Based on post-defect root cause analysis, process parameter control strategies can be optimized, thus establishing a long-term effective interception mechanism;

Usage example: Coating process parameter optimization

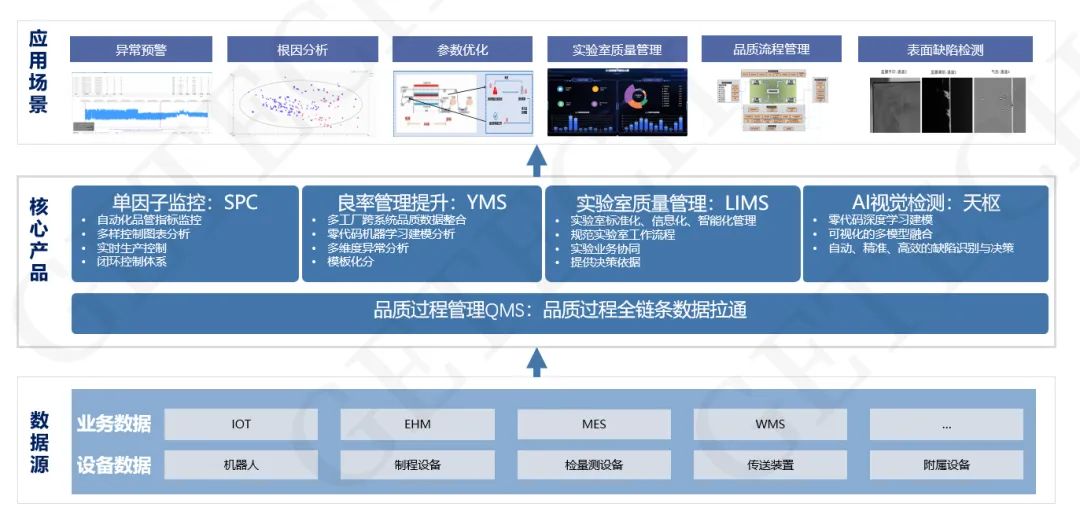

Quality closed-loop control: Use real-time collected process equipment operating parameters and actual measurement result data, use feedback mechanism (Feed back) to establish a clear mathematical relationship between production system data and quality indicator data, correct and optimize equipment parameters without interrupting the production process, when the process deviates from the optimal operating condition, can timely online update production process and process set values, thus ensuring minimal variability in batch product quality, achieving quality stability.As a national cross-industry cross-domain industrial internet platform, GETECH Eastwise uses standardized platforms, industrial applications, and industry solutions to meet the needs of enterprises of different sizes in various industries for intelligent manufacturing.

For lithium battery production quality control, GETECH Eastwise builds a 360° quality control system, combining statistical and AI capabilities to empower quality analysis and optimization, including based on QMS for quality management to achieve full-chain data integration and digital management of quality processes, LIMS for laboratory quality management to achieve intelligent collaboration in laboratory work, with SPC for statistical process control, YMS for yield management improvement, and AI visual inspection as the core to achieve closed-loop control from monitoring and early warning of key quality control points, abnormal root cause analysis, quality prediction to adaptive parameter adjustment in the production process, thus helping lithium battery enterprises achieve the core goals of ultimate yield, ultimate efficiency, and ultimate cost.