GTRONTEC SMT Intelligent Quality Inspection Tool — Boosting SMT Enterprise Quality and Efficiency

2023-12-08

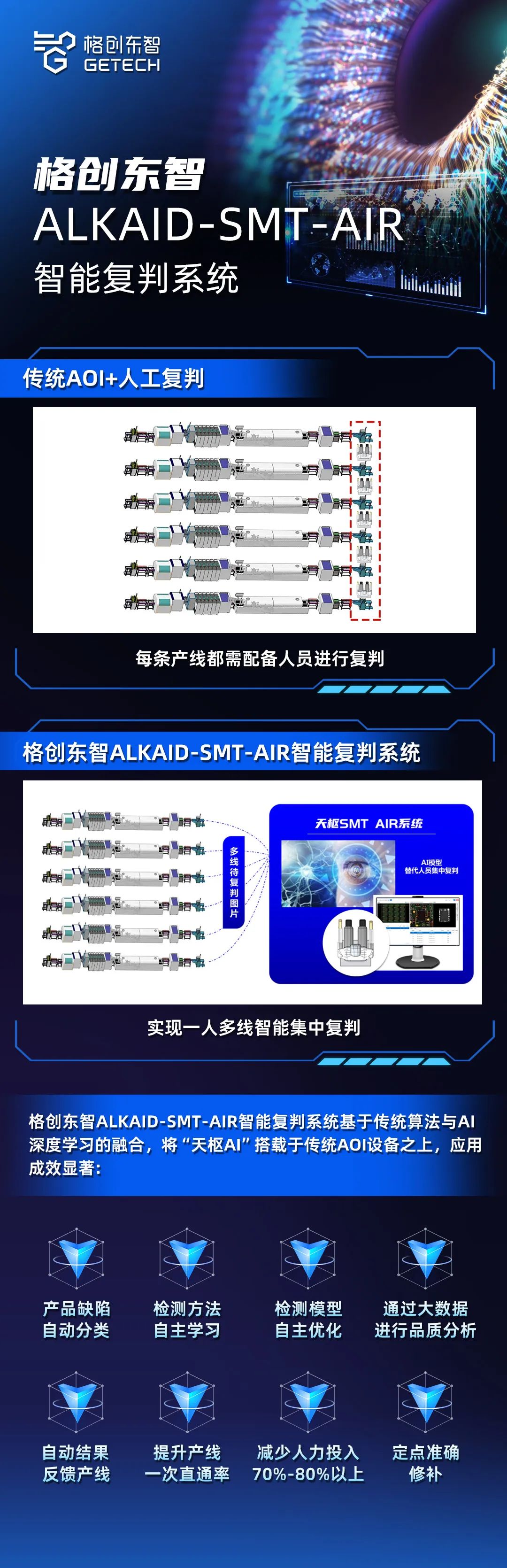

In the SMT manufacturing industry, due to the complexity of actual production scenarios, and most factories have small batches, frequent changeovers, making AOI programs difficult to optimize, some points prone to misjudgment, requiring personnel on each line for online secondary re-judgment. As factories increasingly demand higher first-pass yield and quality rate, the pain points of traditional re-judgment models are obvious:

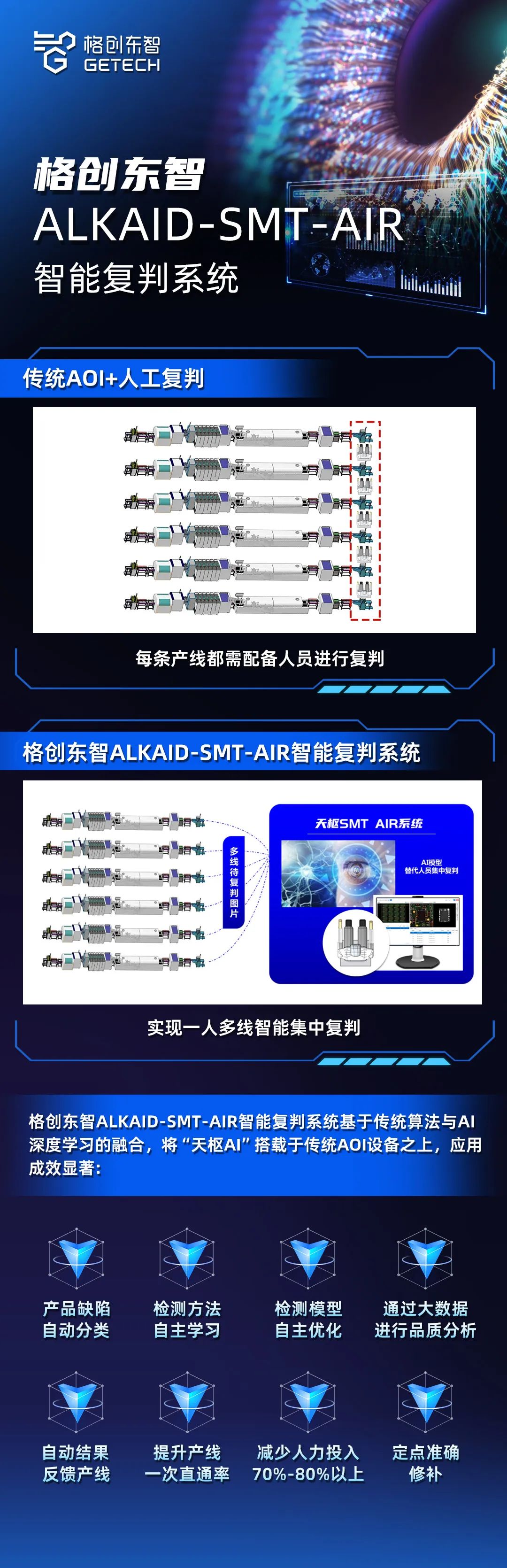

· High investment in re-judgment manpower;· Re-judgment accuracy limited by personnel mobility, proficiency, and subjectivity;GTRONTEC SMT Intelligent Re-judgment System, based on the integration of traditional algorithms and AI deep learning, uses AI servers, one-to-many connection to multiple production lines, replacing manual re-judgment with intelligent re-judgment, achieving:· Centralized multi-line intelligent re-judgment, reducing misdetection, cutting re-judgment manpower by over 80%;· Centralized re-judgment, control signals issued per line, automatic material collection;· Supports cloud connection, defective boards no need for labels, maintenance personnel can remotely query repair information for targeted precise repair;· Intelligent dashboard, overview of production line status, report analysis helps improve first-pass yield and targeted quality rate improvement;· Unified inspection standards, reducing subjective human judgment, decreasing defective outflow.

Currently, GTRONTEC has implemented 'AI replacement solutions' for many

industry leading enterprises,

applying the Tian Shu AI visual inspection system in the SMT field,

inspecting SMT placement and reflow soldering quality,

reducing the false detection rate of post-reflow AOI equipment for SMT products,

cutting SMT AOI quality re-judgment manpower by over 80%,

helping to improve production line first-pass yield.