High-Tech Lithium Battery Interview with Hu Guorong from Central South University: Digital Intelligence Empowers Lithium Battery Cathode Materials for 'Cost Reduction and Consumption Reduction' -- Cop

Abstract

Introducing automation, digitalization, and intelligence to achieve digital intelligent manufacturing production is a key means for lithium battery cathode materials to survive in this round of industry reshuffle.

At the end of 2023, the turning point of the lithium battery market has not yet arrived, and the material end continues to be under pressure. On one hand, affected by the significant expansion in the past two years, the industry has entered a stage of severe structural overcapacity, with high-end capacity and high-quality products becoming the 'hard currency' of the lithium battery market. This poses higher challenges to the manufacturing processing capabilities and large-scale delivery capabilities of material companies.On the other hand, cost reduction remains a necessary condition for material companies to gain operational and supply chain advantages. Under the influence of subsidy phase-outs in the terminal market and oil-electric price parity, the sentiment of extreme cost has spread throughout the entire industry chain, making downstream markets more sensitive to material prices.

Against this background, for lithium battery material companies, especially cathode material companies, they need to improve quality and efficiency while bearing the dual impacts of raw material cost fluctuations and downstream price pressure to survive this round of industry reshuffle. From the industry to enterprises, various solutions are being sought.

In terms of R&D innovation, the mass production and application of new materials such as lithium iron manganese phosphate, high-nickel ternary, and silicon-based anodes are continuously advancing; in supply chain management, integrated layouts and overseas market development are key directions for leading companies; in production management, introducing automation, digitalization, and intelligence to achieve digital intelligent manufacturing production is a critical means.

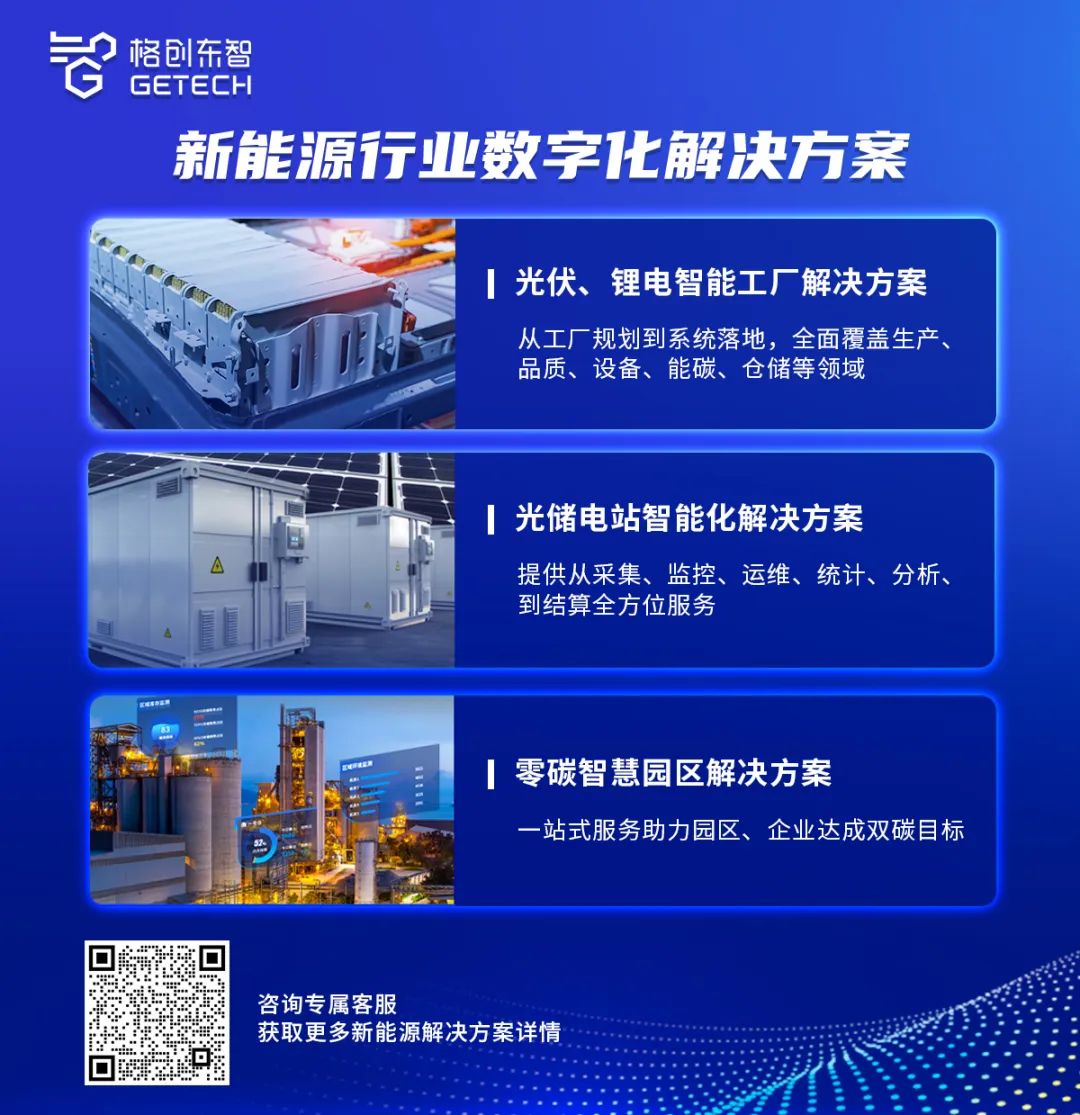

As a globally competitive new energy whole-plant digital intelligence expert, GTRONTEC has been deeply involved in the new energy industry chain for many years, providing new energy companies with full-stack smart manufacturing solutions from consulting to delivery, covering production, equipment, quality, energy, logistics, and other dimensions to offer full-chain digital intelligence upgrades for the new energy industry.

Recently, GTRONTEC signed a strategic cooperation agreement with Professor Hu Guorong's team from Central South University. According to the agreement, both parties will deeply integrate and collaborate closely around the smart manufacturing upgrade of the new energy industry, jointly promoting the intelligent upgrade of lithium battery cathode materials. Additionally, to further strengthen R&D innovation in new energy lithium battery smart manufacturing, GTRONTEC specially appointed Professor Hu Guorong as its new energy expert advisor.

Professor Hu Guorong accepted an interview with High-Tech Lithium Battery. In the interview, Professor Hu provided in-depth insights into the current challenges and risks of the cathode materials industry, future development trends, and how digital intelligence can empower cost reduction and efficiency improvement.

As power batteries enter the TWh era, the production of core lithium battery materials is also leaping to larger-scale capacity. What new challenges are material companies facing? Professor Hu Guorong: Currently, the lithium battery materials industry faces two main challenges. First, lithium battery materials are undergoing a conceptual shift from new materials to bulk materials, leading to 'bottleneck' scenarios where single equipment capacity is limited. Additionally, if production lines use multiple equipment from different suppliers, it can affect product consistency. Second, in the era of large-scale manufacturing, requirements for production factors will increase. In the cathode materials field, industry profits are gradually decreasing, making cost requirements for production factors more sensitive. Companies need to choose locations with cost advantages for production factors and continuously贯彻 the 'extreme cost' concept in the manufacturing process.

With huge cost reduction pressure on power batteries, how can digital intelligence achieve cost reduction and efficiency improvement in the materials segment? How can it help upgrade the cathode materials industry and bring substantial changes to companies? Professor Hu Guorong: Digital intelligence will助力 material industry升级 through improved R&D efficiency, data-driven process and quality optimization, intelligent material production control, and full lifecycle management of material equipment. In terms of product quality, digital intelligence will help enhance product quality and consistency. Due to the many processes in material production and numerous factors and indicators affecting quality, digital intelligence can more precisely把握 and control these indicators; digital models and platform management can achieve human-machine collaboration after capacity increase, thus improving consistency. In terms of cost reduction, full digitalization from R&D to production will significantly reduce costs. In R&D, under the background of material genomics, digital computing can simulate through mathematical models, reducing new material R&D costs and trial-and-error costs; in production, with many equipment and processes in material production, implementing full intelligence and digitalization in process control, quality management, and social management can increase yield rates while reducing energy consumption; in equipment, with the trend of larger manufacturing equipment and scaled production lines, digital intelligence can improve equipment utilization, rationally regulate resource use, reduce production energy consumption, and thus increase processing profits. Additionally, digital intelligence will also assist material companies in going global. Overseas labor costs due to legal regulations and cultural differences have been a困境 for lithium battery companies expanding abroad. Digital intelligence can help companies achieve remote control, reducing labor costs.

Strengthening carbon management and achieving carbon reduction or even zero carbon has become an important consideration for the lithium battery industry. As a segment with high energy consumption in the industry chain, how can material companies promote zero-carbon transformation? Can digital management better promote carbon footprint tracing and carbon reduction? Professor Hu Guorong: The lithium battery materials industry itself is a high-energy-consumption manufacturing sector. For example, producing one ton of lithium iron phosphate requires nearly 4,000 kWh of electricity. Additionally, with the advent of large-scale manufacturing, small single equipment capacity in material production leads to low production line capacity levels, resulting in high energy consumption. Digital intelligence will promote zero-carbon production in materials from two aspects. On one hand, using digital intelligence手段 can greatly increase production line capacity, thereby reducing energy consumption. Ten years ago, producing 1 ton of lithium iron phosphate required over 10,000 kWh of electricity; now, with increased production line capacity, electricity consumption has reduced to around 3,000-4,000 kWh. In the future, with the help of digital intelligence, production line capacity could increase 2-3 times, and energy consumption might drop by half or more. On the other hand, in production management and operation, intelligent and digital手段 will optimize production processes and resource utilization, such as adjusting production processing times for different equipment based on peak and off-peak electricity usage, further reducing energy consumption.

What is the current progress of digitalization in domestic lithium battery material companies? What main issues are faced in promoting digitalization? Professor Hu Guorong: Promoting digitalization, intelligence, and automation is a gradual process. Currently, the digital and intelligent transformation in the lithium battery materials industry is transitioning from concepts, goals, and slogans to specific方案落地, gradually penetrating全域 lithium battery factories. In the process of promoting digital intelligence, there are issues in both hardware and software. In hardware, as most production lines in the industry consist of individual digital equipment with uneven levels, achieving overall full intelligence still has many problems to solve; in software, the digital level of production line operation management in material companies is relatively low, especially in quality control, such as anomaly alerts and product tracing, where defects still exist.

GTRONTEC and Professor Hu Guorong's team have joined forces to promote the intelligent upgrade of lithium battery cathode materials. What is the specific progress? How will it empower the digital intelligence construction of the cathode materials industry? Professor Hu Guorong: The lithium battery industry is a野蛮生长 industry that has achieved从无到有, and is now in the从有到好 development stage, requiring companies with experience and technical advantages in various细分 fields to lead and empower. Among them, GTRONTEC, as a TCL strategically incubated company, will fully leverage the technological and experience advantages accumulated in the semiconductor industry to provide full-chain digital intelligence upgrades for the new energy industry. I have been engaged in the R&D of lithium battery cathode materials since 1998, and for GTRONTEC, I will fully发挥 my expertise, working with GTRONTEC to focus on long-term and strategic major challenges in new energy smart manufacturing that need breakthrough and development, researching and implementing new technologies and models, and promoting innovation and upgrade in new energy industry smart manufacturing. This cooperation will involve sharing technology, talent, and market resources in the lithium battery cathode materials industry,致力于 application system development and project successful implementation, promoting the intelligent upgrade of lithium battery cathode materials.同时, both parties will jointly research big data to empower R&D efficiency improvement, data-driven process and quality optimization, intelligent material production control, full lifecycle management of cathode material equipment, and energy and dual-carbon management solutions.

Postscript: Professor Hu Guorong is a professor and doctoral supervisor at Central South University, a State Council special allowance expert, and currently the deputy director of the Technical Committee of the Advanced Battery Materials Engineering Research Center of the Ministry of Education. His research team on lithium battery materials is one of the earliest in China engaged in the R&D and industrialization of lithium battery cathode materials, with科研成果孵化 multiple lithium battery cathode material companies. Central South University, where he is employed, is a leading university in the new energy field,被誉为 the 'Whampoa Military Academy' of China's new energy industry, cultivating 75% of the industry's entrepreneurial talent in the domestic new energy battery industry. Core technical personnel from companies like BYD, CATL, Sany Lithium, GEM, etc., also have close ties with Central South University. This cooperation will promote continuous innovation and breakthrough in China's new energy industry digital intelligence field, contributing to new energy digital intelligence upgrade.