2023 GGII Robotics Annual Conference & 10th Anniversary Celebration | GETECH: AIoT Innovation Technology Empowers Future Manufacturing Digital and Intelligent Upgrade

From December 11th to 13th, the 2023 (10th) GGII Robotics Annual Conference & 10th Anniversary Celebration was held in Shenzhen as scheduled. The conference invited over 500 corporate leaders to gather in Shenzhen to discuss major strategic issues such as policies, capital trends, and industrial leaps in China's robotics and smart manufacturing sectors. At the event, the 2023 GGII Golden Ball Awards were announced. With innovative breakthroughs in emerging information technologies such as artificial intelligence, big data, and the Internet of Things, GETECH won the Annual Technology Award. Li Nan, General Manager of GETECH's New Energy Business Group, was invited to deliver a keynote speech and participate in a roundtable forum, sharing insights on hot topics such as AIoT innovation technology and the evolution of smart factories.

In his speech, Li Nan pointed out that the transformation and upgrading of manufacturing is a continuous process, having gone through the eras of mechanization, electrification, automation, informatization, and digitalization. In the next 10 to 20 years, it will enter the era of intelligent upgrading. At the same time, corporate development models are shifting from "scale expansion" to "high-quality development." In the intelligent era, the ultimate form of manufacturing factories is about to be realized. Examples include scenario-based intelligent decision-making + automated control, AI blockchain empowering dual-carbon operations, and more. The creation of smart factories relies on the synergistic effect of multiple innovative technologies, with AIoT becoming the key driver for digital and intelligent upgrades in factories.

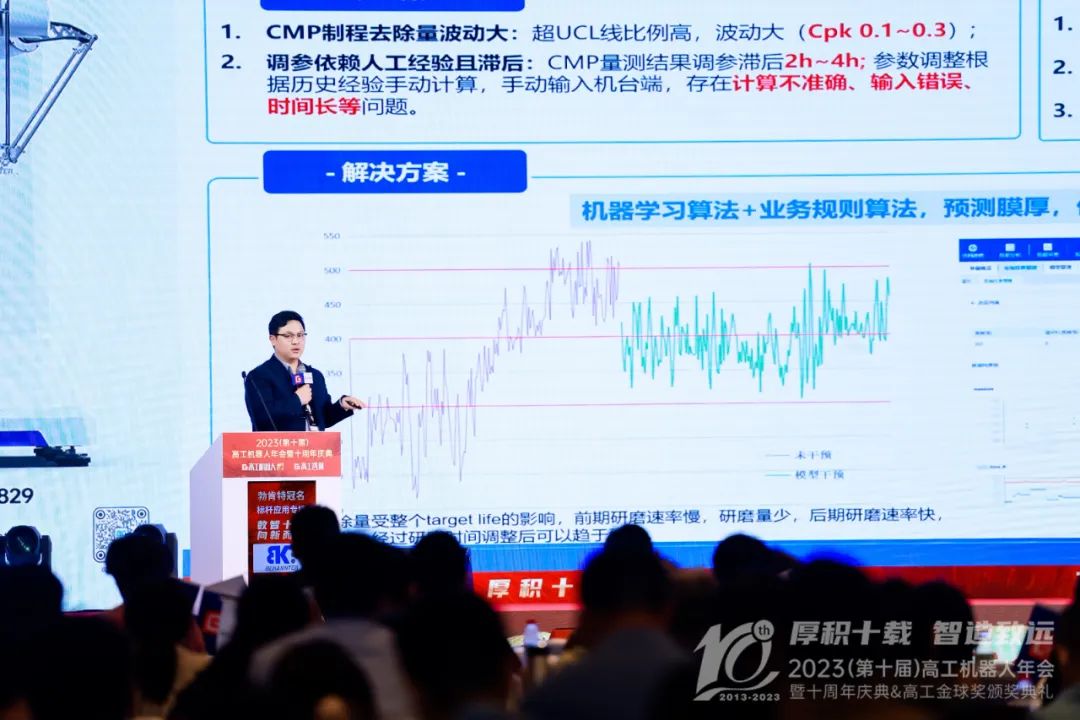

AIoT, combined with technologies like the industrial internet, is redefining industrial collaboration by collecting, processing, and analyzing vast amounts of production and equipment data for manufacturing. The richer and more open the data, the better the efficiency of industrial chain collaboration. Li Nan gave an example: in the quality management of the lithium battery industry, there are pain points such as high safety and consistency requirements, failure to intercept abnormal battery cells in time leading to downstream flow of defective products, and poor data analysis effectiveness. By using formation and capacity data to analyze battery quality, it is possible to provide feedback on battery quality, thereby enabling quality judgment of battery cells, timely interception of abnormal cells, reduction of defective product flow, improvement of yield rates, and guidance for production optimization.

As a national cross-industry platform originating from semiconductor manufacturing, GETECH has strong platform technical capabilities and mature smart factory planning expertise. It has applied AIoT technology to comprehensive data collection, manufacturing system integration, and business closed-loop driving, achieving AI-assisted data decision-making.

In terms of digital quality management, GETECH offers a complete product and service matrix, including QMS quality management, MFA multi-factor analysis, visual inspection solutions ADC, etc. Through integrated one-stop digital solutions, it helps manufacturing industries effectively improve quality management.

In digital energy and carbon management, GETECH's dual-carbon platform integrates equipment IoT, AI algorithms, and edge control, forming a cloud-edge integrated operating system. Through equipment interconnection, big data processing, AI modeling, and the integration of multiple technology stacks such as equipment mechanisms and algorithms, it forms industrial dual-carbon know-how models, fully leveraging the key role of digitalization in achieving "dual-carbon" goals and maximizing corporate energy and carbon benefits.

Li Nan believes that future factory intelligent upgrading requires accelerating IT+OT integration. To this end, GETECH will promote the establishment of two strategic ecological alliances. First, actively establishing strategic cooperative ecological alliances with industrial control and digital transformation manufacturers to conduct in-depth cooperation and jointly serve the digital and intelligent upgrading of manufacturing. Second, building an industry-education integration alliance, combining "government, industry, and academic" resources to inject fresh blood into the future manufacturing ecosystem.