GTRONTEC AMHS Business Officially Launched, Using AI to Accelerate Semiconductor Software-Hardware Integration

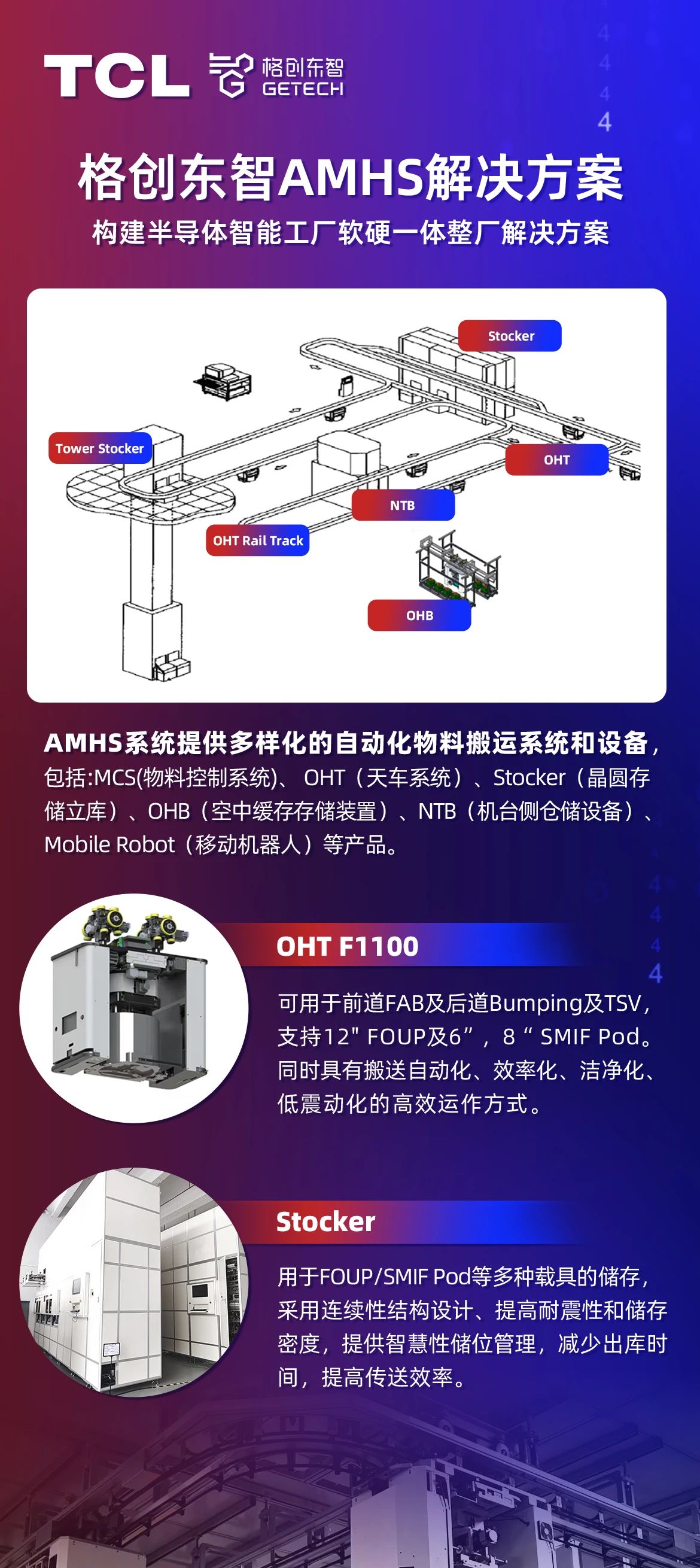

On March 20, GTRONTEC completed the strategic acquisition signing of Yunde Co., Ltd. and Jiangsu Ruixinku Intelligent Technology Co., Ltd., officially launching the AMHS (Automatic Material Handling System) business layout.Thus, based on existing CIM solutions, GTRONTEC further builds a semiconductor smart factory integrated software-hardware whole-plant solution by adding hardware layout, helping semiconductor customers improve production line scheduling efficiency and achieve automation, digitalization, and intelligent upgrade.

AMHS is a very important production auxiliary system in semiconductor factories, covering core hardware equipment such as OHT, Stocker, and operated collaboratively by software such as MCS, RTD, applied in semiconductor materials, wafer manufacturing, and packaging testing links,utilization rate, crucial for improving core production indicators such as capacity, utilization rate, and yield rate.

In recent years, with the vigorous development of China's semiconductor industry, there is an increasing demand for automation transformation in more and more wafer fabs, silicon wafer factories, and packaging and testing factories, posing higher requirements for the AMHS system.AMHS is the automation hardware most closely integrated with semiconductor CIM software,GTRONTECwill rely on its existing advantages to continuously enhance its core competitiveness in the AMHS field, create integrated software-hardware whole-plant solutions, and build closed-loop capabilities for production and logistics in semiconductor factories.

As an industrial intelligent solutions provider originating from semiconductor manufacturing, GTRONTEC always firmly implements the software-hardware integration strategy, deepens IT and OT integration, sinks into the industrial site,fully utilizes the advantages of emerging technologies such as AI, cloud computing, big data, drives the intelligent upgrade of equipment and edge control hardware with software and algorithms, accelerates industrial intelligent innovation and change, helps semiconductor factories build group control and centralized control capabilities, and achieves full-factor connection, transparent production execution, and automated equipment management.Currently, GTRONTEC has built multiple smart factories for semiconductor customers and accumulated extensive project implementation experience in semiconductor CIM systems and automation fields.