Building a Semiconductor Digital Intelligence Laboratory: Several LIMS Projects of Gec Dongzhi Successfully Launched

Recently, Gec Dongzhi successively launched LIMS projects for Jiangsu Xianke Semiconductor New Materials Co., Ltd. and Jiangsu JJJ Microelectronics Co., Ltd., helping customers comprehensively upgrade their semiconductor digital intelligence laboratory management platform. This enables optimized allocation and efficient utilization of laboratory resources, improves laboratory work efficiency and management level, and provides strong support for R&D innovation.

Jiangsu Xianke Semiconductor New Materials Co., Ltd. is a semiconductor materials manufacturer. Limited by issues such as untimely maintenance services from foreign suppliers, low communication efficiency, and outdated product technology, there is an urgent need to upgrade the original LIMS system. Focusing on customer needs, Gec Dongzhi will help customers achieve domestic replacement of the LIMS system, expand the functional scope of physical and chemical laboratories, and strengthen technical capabilities such as automatic data collection, further enhancing the laboratory's digital intelligence level.

Jiangsu JJJ Microelectronics Co., Ltd. is a leading domestic high-quality power semiconductor device IDM and thyristor industry leader. Its laboratory management faces challenges such as diverse types of experimental testing, high complexity in testing processes, and difficulties in unifying quality management systems and processes. Addressing the customer's business characteristics, Gec Dongzhi will introduce advanced laboratory management concepts and information management systems, providing basic functions such as reliability assurance, characteristic testing, failure analysis, ESD, and metrology, as well as comprehensive laboratory management business functions involved in CNAS laboratory accreditation. This will significantly optimize the laboratory testing management system and improve management efficiency.

As semiconductor factories with "zero tolerance" for errors, strict laboratory verification testing is indispensable before product mass production and during the production process, directly impacting product yield and quality. Faced with numerous projects, complex processes, and massive amounts of data... further improving efficiency and reducing error rates make the LIMS laboratory information management system an essential configuration.

Gec Dongzhi's LIMS is based on the CNAS laboratory management system, involving 25 major elements (15 management elements and 10 technical elements). It covers end-to-end business processes and core management requirements, building a semiconductor factory laboratory management platform that effectively enhances the standardization, informatization, intelligence, and automation management level of semiconductor factory laboratories, meeting the high-quality demands of laboratories.

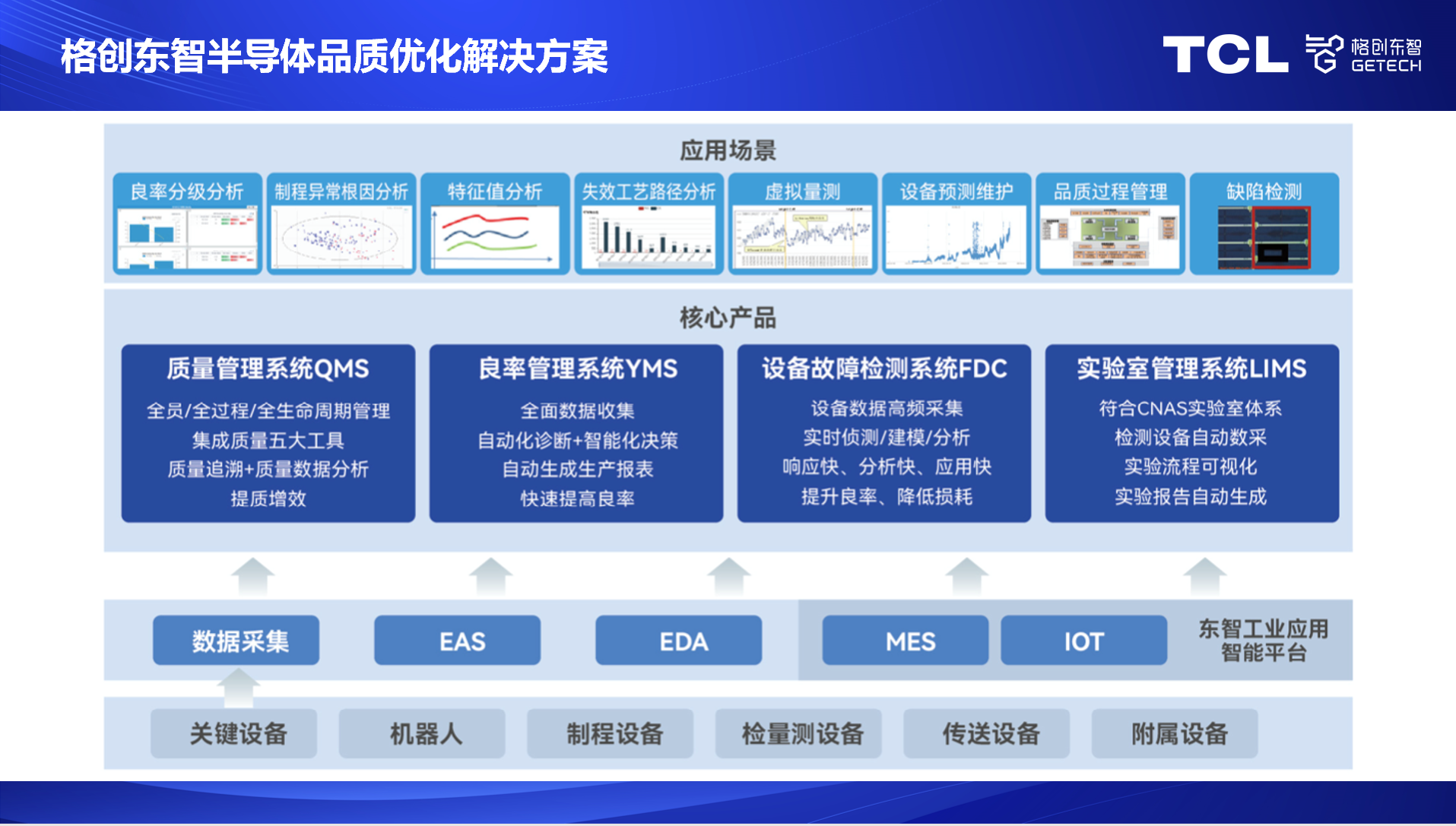

Currently, under China's core economic development strategy of high-quality development, the manufacturing industry increasingly emphasizes quality transformation, adhering to the principle of quality first. Leveraging emerging technologies such as AI and big data to achieve higher quality has become an industry consensus. Gec Dongzhi provides comprehensive quality solutions, including quality management system QMS, yield management system YMS, equipment fault detection system FDC, and laboratory quality management LIMS. Combined with AI algorithms and big data, it empowers quality analysis and optimization, helping semiconductor companies achieve the core goal of极致良率 (ultimate yield).

Using "intelligence" to enhance quality, Gec Dongzhi will continue to leverage its technological advantages, working with customers to transform more emerging industrial intelligent technology achievements into practical productivity, injecting continuous new momentum into high-quality development.