GTRONTEC Lithium Battery Material Solution Heavily Featured at Chongqing International Battery Technology Exchange Exhibition

Recently, the 16th Chongqing International Battery Technology Exchange Conference/Exhibition was held at the Chongqing International Expo Center. As one of the most influential new energy exhibitions globally, it attracted over 2000 industry leaders, gathering government, industry, academic, and research resources from the battery industry's upstream and downstream, focusing on industry hotspots,洞察 future trends, providing new perspectives and practical paths for industry升级, and strong support for high-quality development.

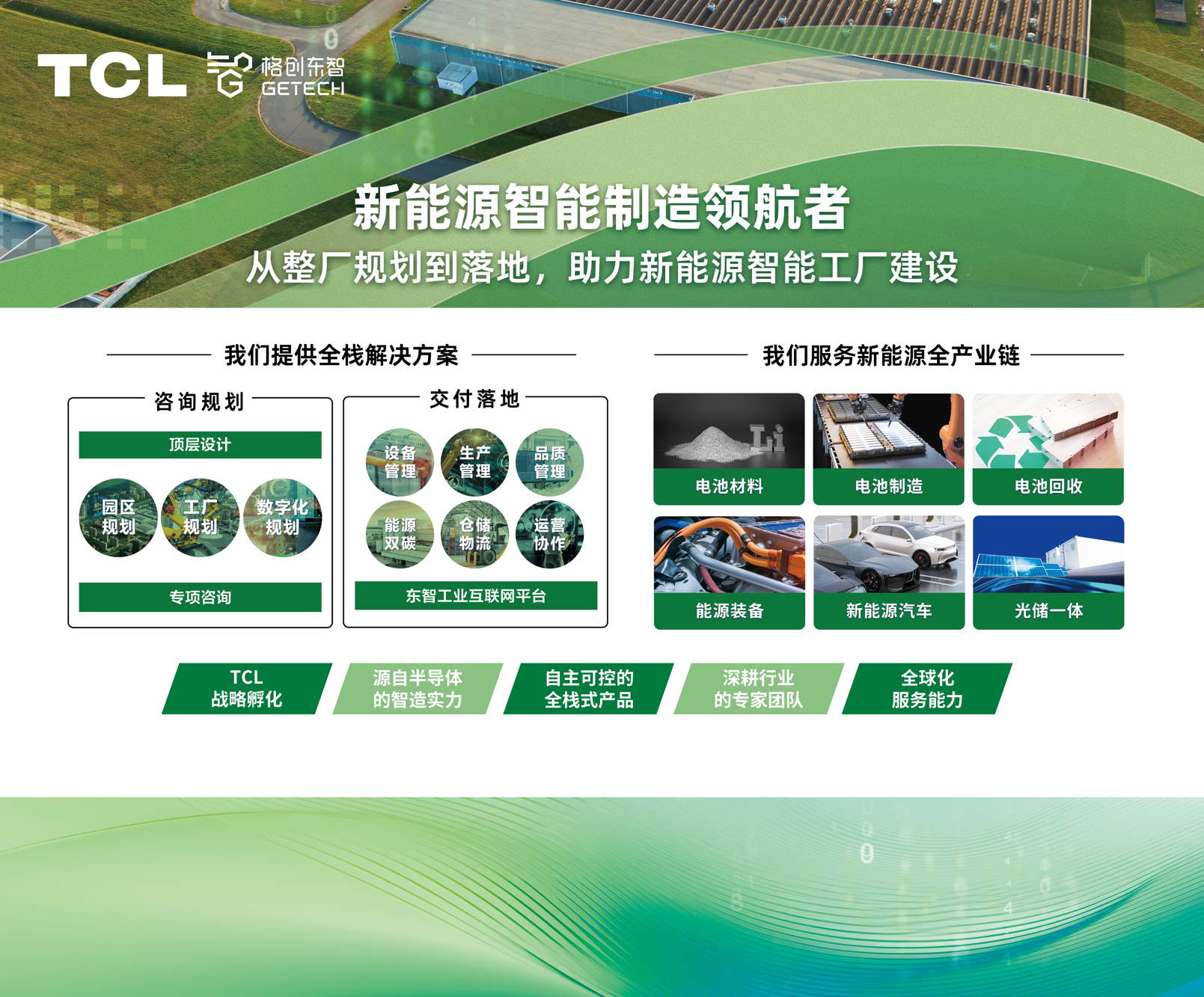

GTRONTEC deeply showcased its full-stack new energy digital intelligence solution from consulting and planning to delivery at this exhibition, targeting lithium battery materials, manufacturing, recycling, energy equipment, new energy vehicles, integrated photovoltaics and storage, and other fields, assisting the entire new energy industry chain in building smart factories. Among them, the lithium battery material industry solution received significant attention.

In the lithium battery material industry, issues such as difficult batch management, poor consistency in manual control, challenging material control, slow capacity improvement, and high detection difficulty have always been pain points for enterprises. Especially under the current industry situation of structural overcapacity, lithium battery material companies urgently need to introduce digital and intelligent solutions to achieve extreme efficiency, extreme cost, and extreme yield through smart manufacturing, enhance core competitiveness, and navigate industry cycles.

Addressing the above needs and pain points, GTRONTEC's lithium battery material solution focuses on data-driven process quality management and optimization, intelligent material production control, comprehensive equipment and energy-carbon management, etc., to help lithium battery materials reduce costs and increase efficiency, achieving digital intelligence upgrade for the industry.

For example, GTRONTEC's intelligent production control solution will help improve product quality and consistency. Through digital process driving and control based on Batch and APC, it achieves automatic production scheduling calculation and release control, greatly enhancing consistency and obtaining stable production rhythm; and it can solidify the experience of 'master craftsmen' into data models to improve product quality.

On the other hand, with the help of quality digital solutions, it can assist material enterprises in establishing a quality system for materials at various stages, controlling quality data throughout the entire process. The combination of the two can also achieve digital quality management across the entire supply chain, enabling mesh traceability of the entire process's people, machines, materials, methods, and environment.

At the same time, the material industry involves a large number of processes such as crushing and mixing, with many high-speed rotating equipment and high mechanical maintenance requirements. GTRONTEC can help customers achieve real-time monitoring and predictive maintenance of key dynamic equipment, detect degradation trends in advance, and ensure stable production.

Furthermore, as carbon reduction or even zero carbon becomes an important consideration dimension in the lithium battery industry, lithium battery materials, as a segment with high energy consumption in the industry chain, can also better promote energy-carbon management and carbon footprint tracking through GTRONTEC's solutions.