How can AI+Machine Vision Assist High-Quality Development?

In December 2023, the Ministry of Industry and Information Technology issued the "Implementation Opinions on the Manufacturing Excellence Quality Project," emphasizing that quality is the lifeline of manufacturing and promoting the shift from quantity expansion to quality improvement is a practical need for high-quality development in the new era. In this process, the level of intelligence in manufacturing plants continues to increase. For example, in the field of industrial product inspection, engineers have turned AI into "new workers" to help factories solve challenging problems.

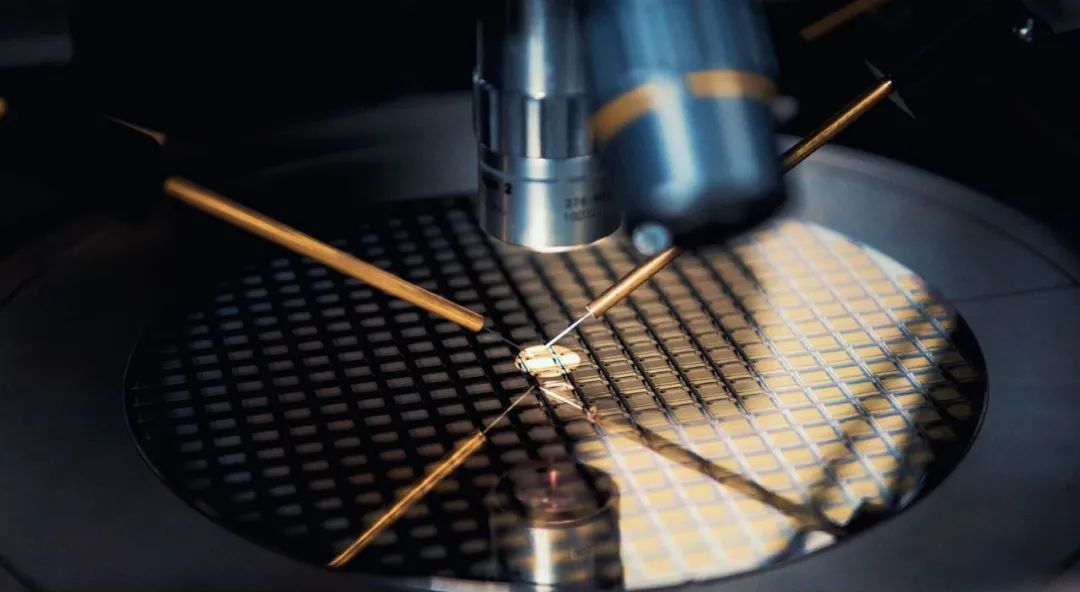

AI Visual Inspection Originating from Semiconductor Manufacturing ScenariosIn 2018, GTRONTEC was incubated by TCL, bringing with it the digital capabilities TCL accumulated in solving specific problems, and based on this, developed a series of related products and solutions. Deep industry know-how became GTRONTEC's natural advantage. Unlike some AI companies that seek scenarios and customers with technology, GTRONTEC was born from specific scenarios, giving it a strong innate understanding of scenarios and customer needs. GTRONTEC's machine vision inspection solution—Tianshu AI Visual Inspection System—is a small branch of its industrial intelligence solutions, originating from TCL Huaxing's semiconductor panel production inspection. Each key process in panel production requires AOI (Automatic Optical Inspection) equipment to capture images and identify related defects. Initially, defect classification was done manually; only after classification could the next steps be determined. The entire process involves over a hundred steps, requiring extensive manual labor for each key process. With the rise of machine vision technology, GTRONTEC collaborated with TCL Huaxing to develop an AI visual inspection system, using artificial intelligence technology for image recognition and classification. After implementation, the system significantly improved inspection efficiency, replacing 80-90% of inspection personnel and processing nearly three million images per day. It also enhanced inspection accuracy by effectively avoiding issues like human fatigue and cognitive differences between individuals. Subsequently, as technology matured, GTRONTEC's machine vision solutions gradually expanded beyond the semiconductor industry and have now successfully empowered 22细分 industries, including photovoltaics, 3C electronics, home appliances, petrochemicals, and aerospace.

GTRONTEC, which has long pondered how to make machine vision systems better and easier to implement, actively responded to the large model trend, training and developing its own large models based on extensive existing data and small models. However, directly deploying large models on the client side posed new challenges, such as high resource consumption for推理 needs in real-time industrial scenarios and cost pressures难以 meeting the requirements for continuous rapid inspection and seamless integration with production processes. GTRONTEC's solution was to first train large models internally and then perform "model slimming" for specific scenarios. This approach leverages large models for learning and feature extraction, enabling more efficient training of small models with significantly reduced data requirements, making model implementation more convenient and feasible. Additionally, to improve product deliverability, the Tianshu AI Visual Inspection System developed visualization features, simplifying the model development process into intuitive drag-and-drop operations, allowing even non-AI expert IT personnel to easily develop and optimize AI models. Customers can choose from a series of preset sub-models and algorithms, combining them through simple operations to build models that meet specific needs without delving into complex algorithmic details. This way, many customer companies can benefit from the latest machine vision technology without additional huge human resource costs. How much impact does AI have on the industrial intelligence process? Beyond machine vision, industrial intelligence applications can effectively improve product quality through precise control, intelligent analysis, automated production, quality traceability, and other means, leading the digital transformation and upgrading of manufacturing. Enhancing quality with "intelligence," leading the new era of industrial intelligence. On the journey to achieving new industrialization, GTRONTEC will continue to leverage its technological advantages, committed to transforming more integrated software-hardware digital application成果 into practical productivity, injecting continuous new momentum into high-quality development, and exploring the infinite possibilities of industrial intelligence.

AI Visual Inspection Originating from Semiconductor Manufacturing ScenariosIn 2018, GTRONTEC was incubated by TCL, bringing with it the digital capabilities TCL accumulated in solving specific problems, and based on this, developed a series of related products and solutions. Deep industry know-how became GTRONTEC's natural advantage. Unlike some AI companies that seek scenarios and customers with technology, GTRONTEC was born from specific scenarios, giving it a strong innate understanding of scenarios and customer needs. GTRONTEC's machine vision inspection solution—Tianshu AI Visual Inspection System—is a small branch of its industrial intelligence solutions, originating from TCL Huaxing's semiconductor panel production inspection. Each key process in panel production requires AOI (Automatic Optical Inspection) equipment to capture images and identify related defects. Initially, defect classification was done manually; only after classification could the next steps be determined. The entire process involves over a hundred steps, requiring extensive manual labor for each key process. With the rise of machine vision technology, GTRONTEC collaborated with TCL Huaxing to develop an AI visual inspection system, using artificial intelligence technology for image recognition and classification. After implementation, the system significantly improved inspection efficiency, replacing 80-90% of inspection personnel and processing nearly three million images per day. It also enhanced inspection accuracy by effectively avoiding issues like human fatigue and cognitive differences between individuals. Subsequently, as technology matured, GTRONTEC's machine vision solutions gradually expanded beyond the semiconductor industry and have now successfully empowered 22细分 industries, including photovoltaics, 3C electronics, home appliances, petrochemicals, and aerospace.

GTRONTEC, which has long pondered how to make machine vision systems better and easier to implement, actively responded to the large model trend, training and developing its own large models based on extensive existing data and small models. However, directly deploying large models on the client side posed new challenges, such as high resource consumption for推理 needs in real-time industrial scenarios and cost pressures难以 meeting the requirements for continuous rapid inspection and seamless integration with production processes. GTRONTEC's solution was to first train large models internally and then perform "model slimming" for specific scenarios. This approach leverages large models for learning and feature extraction, enabling more efficient training of small models with significantly reduced data requirements, making model implementation more convenient and feasible. Additionally, to improve product deliverability, the Tianshu AI Visual Inspection System developed visualization features, simplifying the model development process into intuitive drag-and-drop operations, allowing even non-AI expert IT personnel to easily develop and optimize AI models. Customers can choose from a series of preset sub-models and algorithms, combining them through simple operations to build models that meet specific needs without delving into complex algorithmic details. This way, many customer companies can benefit from the latest machine vision technology without additional huge human resource costs. How much impact does AI have on the industrial intelligence process? Beyond machine vision, industrial intelligence applications can effectively improve product quality through precise control, intelligent analysis, automated production, quality traceability, and other means, leading the digital transformation and upgrading of manufacturing. Enhancing quality with "intelligence," leading the new era of industrial intelligence. On the journey to achieving new industrialization, GTRONTEC will continue to leverage its technological advantages, committed to transforming more integrated software-hardware digital application成果 into practical productivity, injecting continuous new momentum into high-quality development, and exploring the infinite possibilities of industrial intelligence.