GTRONTEC Expert Shares: Dual Carbon Management and AI Applications for New Energy Vehicle Enterprises and Parts Factories - Replication

Recently, Wang Hui, General Manager of GTRONTEC's Energy Dual Carbon Business Unit, was invited as a guest speaker to attend the 2024 Digital Technology and Automotive Industry Application Conference, the 2024 Digital Innovation Talent Empowerment Equipment Manufacturing High-Quality Development Exchange Event, and the 2024 China Automotive High-Quality Development Intelligent Manufacturing Forum. He shared insights on dual carbon management and AI applications in China's automotive industry, gathering with over 1,000 R&D, production, and engineering technicians from vehicle manufacturers and parts producers to discuss digital transformation and green, high-quality development around scenarios like digital technology and future smart factories in the automotive industry.

Four Major Challenges for High-Quality, Green, Low-Carbon Development of New Energy Vehicles

Wang Hui pointed out that the domestic new energy vehicle and parts industry, aiming to achieve high-quality, green, low-carbon sustainable development, generally faces severe challenges from four aspects: national dual carbon control policies, global trade competition requirements, supply chain pressures, and intensified industry competition:

First, the national level has put forward more explicit and specific policy requirements for the transition from 'dual control of energy' to 'dual control of carbon.' For example, in the document 'Opinions of the National Development and Reform Commission and Other Departments on Accelerating the Establishment of a Product Carbon Footprint Management System,' the fourth of the five key tasks clearly states: Enrich application scenarios for product carbon footprints. Focusing on large consumer goods such as electronic products, home appliances, and automobiles, promote the application of carbon labels in an orderly manner.

Second, requirements from global trade competition. The vast automotive and parts industry chain is highly globalized. Whether it's the EU's new battery regulations, carbon dioxide emission standards for passenger vehicles, or the increasing emphasis on ESG disclosure requirements in global financial markets, higher demands are placed on carbon footprint disclosure and energy-saving and carbon reduction throughout the industry chain.

Third, upstream chain leaders like vehicle manufacturers have set clearer requirements for dual carbon goals. For instance, automakers such as BMW, Audi, BYD, and Volvo have proposed their own carbon peak and carbon neutrality targets, along with a series of energy-saving and carbon reduction measures and clear pathways. Additionally, some vehicle manufacturers like Geely require suppliers to provide self-assessment surveys on sustainable development and complete ESG on-site audits or third-party due diligence.

Fourth, as industry competition intensifies, more companies are demanding extreme cost reduction and efficiency improvement. Manufacturing plants for automobiles and power batteries are typical high-energy-consuming industries, with energy costs for a single production plant often reaching hundreds of millions of RMB. For some power battery factories, energy costs can account for 2%-5% of the cost per Wh of battery packs, and in some cases, even up to 8%. In an era of fierce market price competition, every penny saved in costs can effectively enhance a company's market competitiveness.

One Benchmark and Three Dimensions

To address these significant challenges, companies need to systematically and comprehensively consider green, low-carbon development strategies, setting reasonable, effective, and clear dual carbon goals and pathways. The formulation of dual carbon goals should not only focus on the long term but also be grounded in the present, balancing the achievement of strategic goals with short-term operational objectives.

Currently, mainstream dual carbon goal-setting standards and solutions in the industry are diverse, each with its own advantages and disadvantages. However, regardless of the method or system, companies need to consider their dual carbon strategy from one benchmark and three dimensions:

One benchmark refers to the need for companies to establish a carbon reduction baseline and targets after clarifying their carbon emissions.

Three dimensions refer to the three main pathways for dual carbon goals: energy supply-side adjustment, energy consumption process energy-saving, and post-consumption emission management.

In this process, digitalization is a crucial tool for achieving goals and economic benefits.

For example, on the energy supply side, software systems are needed to manage and control new energy facilities like wind, solar, storage, and charging, enabling energy operation and dispatch control. During energy consumption, digital systems are required for process control and energy consumption analysis of utilities like water, electricity, and gas to identify and improve energy waste points. After energy consumption and carbon emissions occur, digital systems can accurately and quickly verify overall carbon emissions and effectively manage carbon assets for value addition.

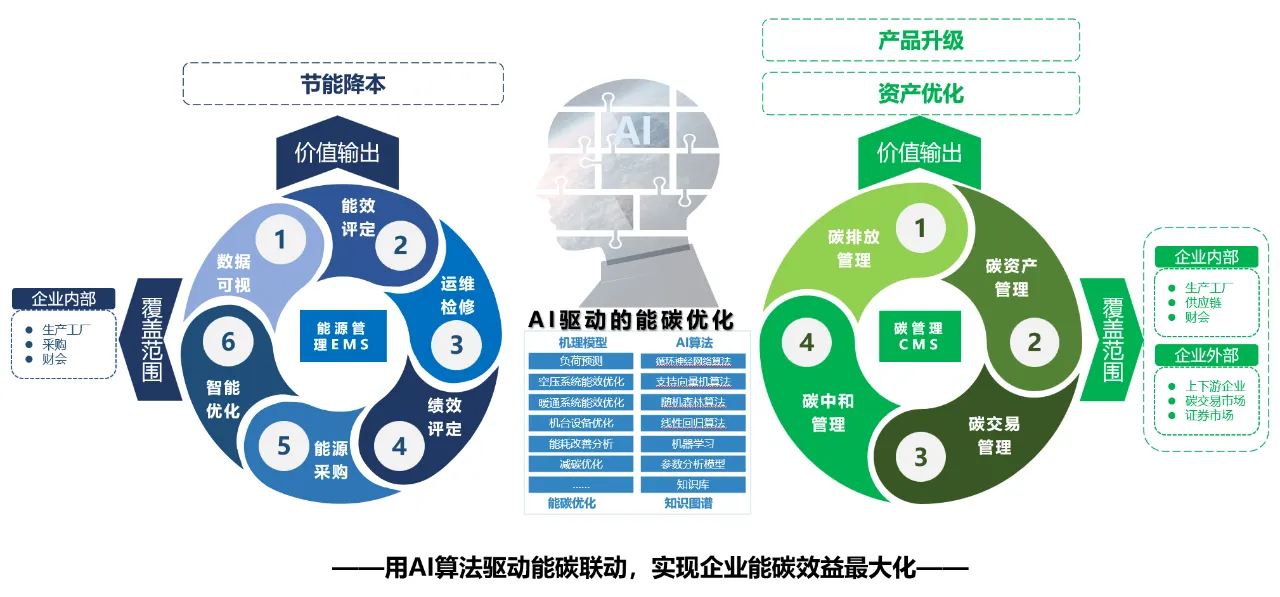

The market now offers an increasing variety of dual carbon digital tools, giving companies more options to select suitable digital tools for dual carbon management. However, overall, due to the lengthy chain from energy supply to consumption and emissions in the dual carbon industry, and the varying complexity across different sectors, these tools show a divergent trend in energy optimization and carbon management. Tools for energy management often lack effective means for carbon management, while carbon management tools struggle to provide practical energy-saving products, failing to offer end-to-end integrated energy-carbon solutions for users.

Especially with the growing prevalence of AI tools, there is still a lack of effective AI tools to assist companies in dual carbon digitalization. To maximize energy-carbon value, companies must integrate and holistically manage the entire chain from energy supply to consumption and emissions, achieving optimal energy-saving benefits, carbon asset gains, and ultimately, core competitiveness in green, low-carbon products.

GTRONTEC Energy Carbon Brain

An Effective Tool for Companies to Achieve Dual Carbon Goals

As an industrial intelligent solutions provider incubated by TCL, GTRONTEC has accumulated extensive dual carbon practices in both discrete and continuous manufacturing over the years, forming the industry-leading Energy Carbon Brain platform that addresses companies' needs for energy adjustment, energy-saving, and carbon management. This platform is now widely used in the automotive industry chain.

Taking TCL CSOT as an example, as a key supplier in the automotive industry chain and one of the world's leading manufacturers of automotive displays, it set clear dual carbon goals and implementation pathways in 2023. GTRONTEC, as the digital provider for TCL's dual carbon practices, has delivered comprehensive dual carbon digital solutions to dozens of factories within the group. While serving TCL, GTRONTEC also externalizes its achievements. Over 70 manufacturing factories across 22 industries now use GTRONTEC's Energy Carbon Brain system, cumulatively saving over 250,000 tons of carbon dioxide, including some global leading vehicle factories. Additionally, more than half of the top ten new energy battery companies in China use GTRONTEC's Energy Carbon Brain products.

For instance, an automotive manufacturer, driven by dual carbon strategy development and energy-saving efficiency needs, sought to improve the energy efficiency of energy stations across multiple vehicle manufacturing plants and initiated HVAC room improvement projects. After in-depth analysis and research of the company's existing room operation data and system issues, GTRONTEC aimed to build high-efficiency rooms. Using AI algorithms, mechanistic models, data cloud computing, and other technologies, GTRONTEC improved room energy efficiency, optimized control, and automated data reporting and推送. This ultimately achieved a 20% increase in management efficiency, a 10% improvement in comprehensive room efficiency, and a comprehensive COP above 5.3, reaching internationally advanced levels of high-efficiency rooms.

After years of continuous R&D investment and iteration, GTRONTEC's Energy Carbon Brain system has formed a '1+3+N' product service system: one platform, three applications, and N AI algorithm application scenarios. It provides a unified platform base including general energy-carbon modules like energy-carbon IoT, energy-carbon big data, and energy-carbon algorithms. Based on this platform, three core applications have been developed: GTRONTEC Microgrid System for the energy supply side, Energy Management System for the energy consumption side, and Carbon Management System for the carbon emission side. N AI algorithm applications, such as intelligent algorithm scheduling for microgrid systems, optimized control of HVAC and air compression systems in energy management systems, full-site energy load forecasting, and carbon asset optimization recommendation algorithms in carbon management systems, run through various business scenarios.

As an end-to-end intelligent system helping companies manage from energy supply to consumption to emissions, GTRONTEC Energy Carbon Brain is an effective tool for achieving dual carbon goals. In the future, it will serve more automotive and parts enterprises, supporting China's new energy vehicle and related industries in achieving dual carbon strategic goals.