Success Case | Semiconductor Factory MES Construction, Helping Build Smart Digital Workshop

A certain semiconductor display technology company is an innovative technology enterprise focused on the R&D and manufacturing of semiconductor display technology. One of its factories has built a 3000-square-meter clean room, mainly producing silicon-based OLED micro-displays, flexible OLED mobile screens, automotive display modules, and other products.

The factory's workshop production management was done manually, without using digital systems for control; production equipment operated independently, without networked control, unable to achieve real-time online management or real-time response to production business. The factory urgently needed to upgrade the production management system to achieve refined and flexible management of the entire workshop production, real-time monitoring of production equipment, and build a smart digital workshop.

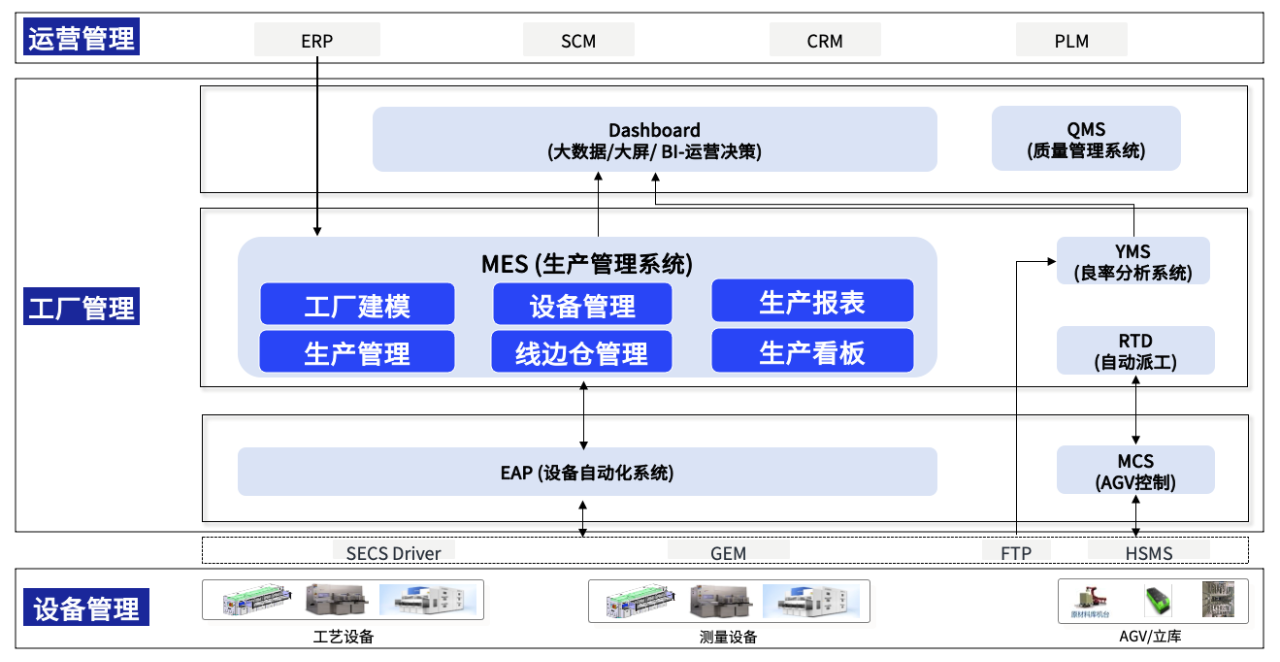

Based on customer needs,GTRONTEC conducted digital transformation for the factory, implementing systems like MES/SPC/kanban/reports to achieve real-time monitoring of production process data, real-time scheduling of production tasks, online control of material usage, and full-process traceability of product information, thereby optimizing the entire production management model, making workshop production more refined and flexible, and building a smart digital workshop that meets enterprise production business control.

GTRONTECMESsystemAfter going live, by improving product quality traceability, production collaboration efficiency, and material management accuracy, the enterprise achieved refined and transparent management of the entire workshop production.

Workshop refined management achieved a 35% reduction in manufacturing cycle and a 22% reduction in delivery cycle.

Introducing the SPC system strengthened quality management, increasing the factory's yield rate by 22%.

Systematic operation management reduced manual input time by 36%, paper document conversion work by 67%, and daily paper operations by 55%.