GTRONTEC's Third-Generation EAP Product Launches, G-EAS Creates a New Generation of Equipment Intelligence Solutions

Recently, GTRONTEC independently developed and launched the third-generation EAP product—G-EAS. Leveraging deep semiconductor industry know-how and software R&D capabilities, and drawing from the world-leading EAP products, technologies, and experience of Fastsems, GTRONTEC’s G-EAS offers advantages in architectural innovation, system stability, operational efficiency, and user experience. In the future, it will also integrate edge computing and AI technologies to create equipment-centric intelligent solutions, improve equipment OEE, and help semiconductor mass production factories enhance production efficiency and product yield.

Innovative Technical Architecture

Strong stability, high performance, high reliability, easy scalability

GTRONTEC’s G-EAS is designed for automation control and management, combining industry needs to develop a new-generation architecture to achieve:

Strong stability: Sustainable operational framework

High performance: Emphasizes business separation and functional decoupling, performance improved multiple times

High reliability: Supports automated service clustering and master-backup solutions, achieving 99.9999% high availability

Easy scalability: User-configurable functions, improving user experience and scalability

New user interface design, visual equipment dashboard, user-friendly experience

GTRONTEC’s G-EAS provides a simple, easy-to-use, and friendly UI interface, creating a unified work platform for users and improving work efficiency.

Equipment dashboard visualization & equipment operation visualization

Four major tools to support efficient implementation and maintenance

Traditional EAP systems often face challenges such as difficult implementation, maintenance, and secondary development. To address this, GTRONTEC’s G-EAS offers four major tools that greatly simplify deployment and configuration processes, reduce maintenance costs, and improve IT operational efficiency.

Implementation and maintenance tool one: Standardized equipment testing templates

Provides typical testing templates for 90% of equipment types (covering semiconductor materials, front-end processes, back-end testing, etc.), improving testing efficiency.

Implementation and maintenance tool two: Visual process editor

Supports secondary development through drag-and-drop operations, lowering technical barriers and enhancing development quality and efficiency.

Implementation and maintenance tool three: One-click service setup and management

Installation, startup, shutdown, uninstallation, batch upgrades, and other services can be performed with one click, reducing system maintenance difficulty and cost while improving operational efficiency.

Implementation and maintenance tool four: Real-time monitoring and fault tracking

Enables real-time status monitoring, alerts, and keep-alive for background running programs; when business logic errors occur, the system provides a user-friendly log tracking and reproduction method, achieving 'early detection, fast localization, quick repair, and early resumption'.

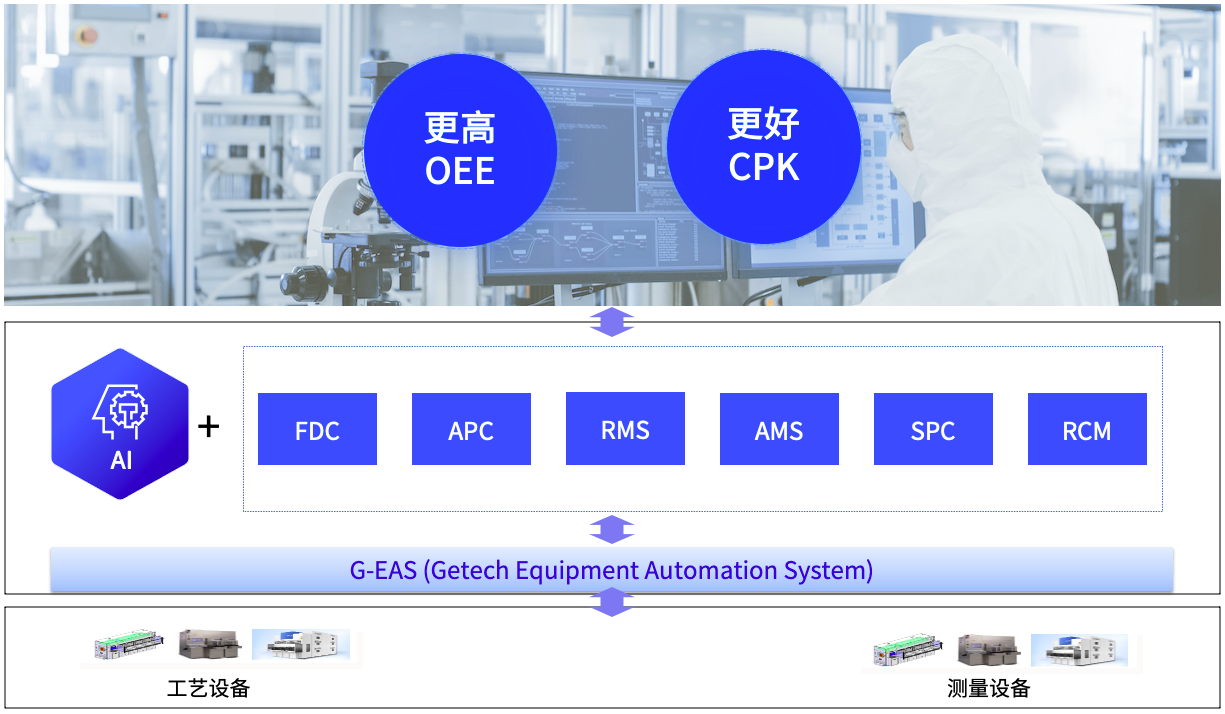

Integrating AI technology

Creating equipment-centric intelligent solutions

The core members of GTRONTEC’s G-EAS product team are seasoned professionals in the semiconductor industry. They are familiar with equipment and industry trends, enabling them to provide semiconductor factories with a complete set of equipment automation solutions.

In addition to the architectural innovation, system stability, operational efficiency, and user experience mentioned above, G-EAS also offers the following values to semiconductor factories:

Supports SECS/GEM standards and non-standard equipment

Supports rapid equipment testing, deployment, and launch

Ensures system stability and sustainable operation in mass production lines

Improves overall equipment system security, implementing new SEMI E187/E188 standards

Future functional expansion, equipment combination, and new data collection

In the future, based on the released G-EAS system, GTRONTEC will integrate edge computing and AI technologies with existing products like FDC/SPC/APC/AMS to form equipment-centric intelligence, achieving higher OEE, better CPK, making equipment smarter and industry wiser.