Stable and efficient AMHS will become a 'must-have' for semiconductor factories

As semiconductor production line processes become increasingly complex, traditional material handling methods between production line equipment have become a bottleneck constraining production efficiency and quality. Therefore, the AMHS automatic material handling system emerged and is gradually becoming popular in semiconductor wafer manufacturing.

The characteristics and application value of the AMHS system are mainly reflected in: high reliability, high automation and informatization, high efficiency, high flexibility and scalability. GTRONTEC Dongzhi believes that with the continuous evolution of semiconductor technology, the size of wafers is increasing, making semiconductor factories require higher levels of automation and informatization technology. Therefore, in the medium to long term, new semiconductor factories will consider AMHS as a 'must-have', with demand mainly体现在 high automation, intelligence, informatization, high reliability and security, as well as certain flexibility and scalability, to reduce dependence on humans and improve the utilization rate of production equipment and inventory turnover.

The overall cleanroom AMHS solution centered on the OHT system has the greatest advantage in its very high efficiency, and its main layout is in the air, not occupying ground space. Because cleanrooms are 'every inch counts', the application of the OHT system can release more space for layout, used to increase equipment and expand capacity. However, in some process segments, such as those requiring dry and wet processes, or with high flexibility and high precision application needs, overhead cranes may not be suitable, and combination with equipment like AGVs needs to be considered.

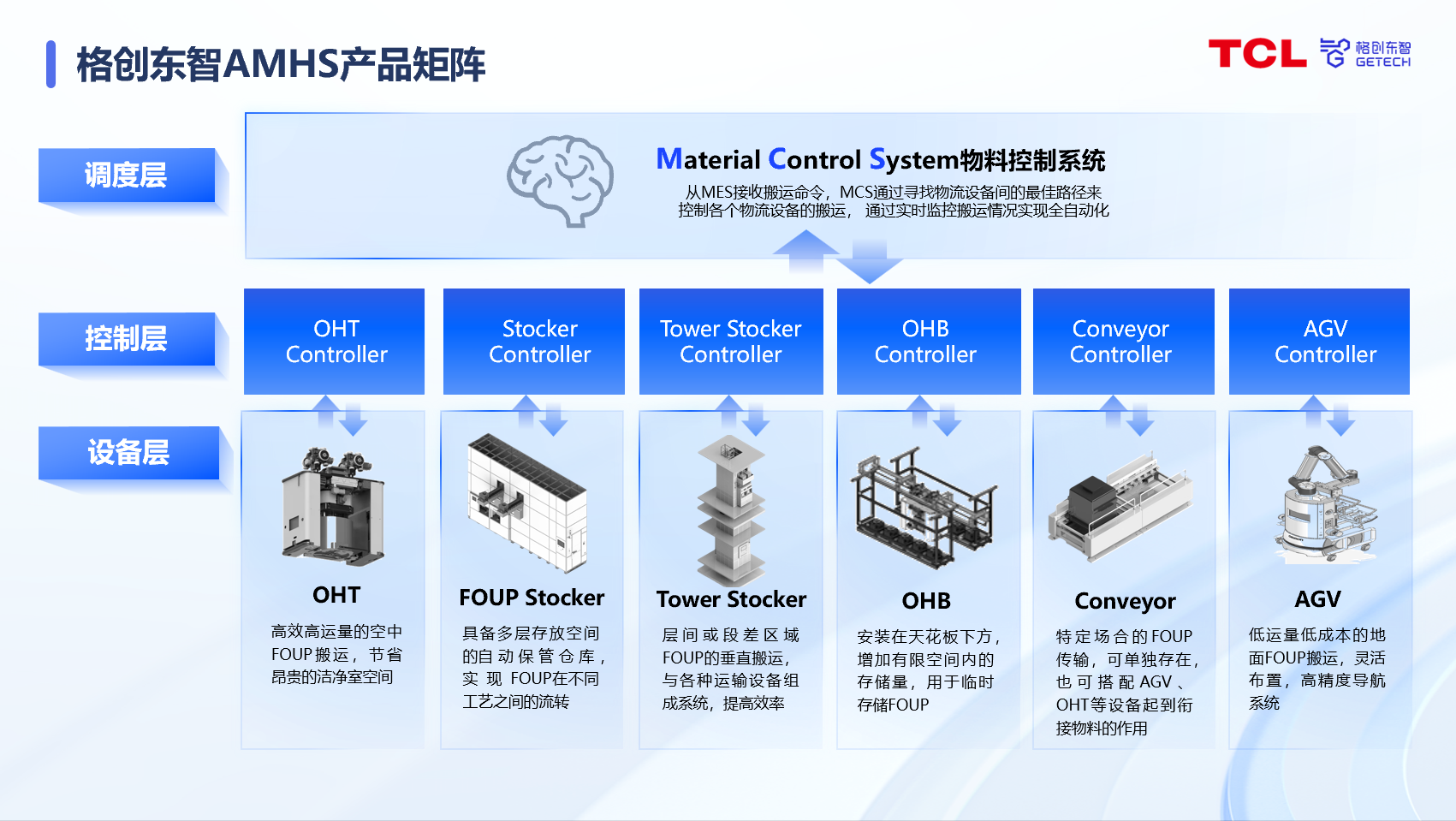

At the same time, the intelligent scheduling system is also noteworthy, which is an area that domestic AMHS manufacturers are focusing on developing. For AMHS, how to achieve rapid response of the scheduling system and MCS (Material Control System) to production peaks and valleys, and adapt to process adjustments, is a key focus for AMHS manufacturers to break through in the future.

Additionally, it can be further extended with dataization and informatization. Currently, more and more owners attach great importance to mining and analyzing production data, aiming to understand every aspect of the production process, discover potential problems, and propose improvements. This work also brings great value to AMHS. For example, by analyzing the rhythm of material handling, turnover情况, and equipment utilization率, process layout, equipment configuration, and scheduling strategies can be optimized.

GTRONTEC Dongzhi AMHS Application Innovation

Stability and efficiency are important indicators of AMHS system performance. To address these indicators, GTRONTEC Dongzhi introduces its existing advantages in preventive maintenance and energy consumption management into the AMHS solution.

1. Equipment Fault Detection and Classification System (FDC)

Real-time collection of equipment status data and process parameters during production, through monitoring models to achieve detection and intelligent analysis of failure modes in the production process. This application can perform preventive and predictive maintenance on AMHS, using IoT technology and AMHS to collect material transfer information for judgment. Through AI model building, it helps users' operation and maintenance teams reduce downtime, enhance the robustness of logistics lines and automated production lines, and help semiconductor factories improve the efficiency and reliability of production equipment, achieving the development goals of extreme yield, extreme efficiency, and extreme cost.

2. Smart Energy Management System (EMS)

Semiconductor factories are one of the high-energy consumption industries, with energy consumption mainly coming from manufacturing equipment and ventilation and air conditioning systems. Based on analysis of historical data, we found that there is some redundancy. For example, cleanrooms in semiconductor factories need to maintain certain humidity and temperature, but the control of turning ventilation and air conditioning equipment on and off has great potential to be explored. The same applies to equipment applications in AMHS. We can integrate the entire material informatization and all equipment informatization systems, combined with AI algorithms to provide customers with optimal energy management for when to turn on/off, helping them reduce energy consumption and carbon emissions, thereby achieving production development effects of energy saving, emission reduction, consumption reduction, and efficiency improvement.