Success Case | EMS Energy Management System Construction for Power Battery Unicorn, Building Full Lifecycle Energy and Carbon Management

1. Domestic and international policy requirements: For the new energy battery industry where the client operates, policies and regulations on energy saving, carbon reduction, and green development are being accelerated both domestically and internationally, imposing new and higher requirements on the industry's development. Examples include the "Lithium-ion Battery Industry Standard Conditions (2021 Edition)" and the EU's "New Battery Law".

2. Lack of digital means: The client requires high real-time data, with massive and complex datasets. How to analyze, measure, bill, and account for vast and complex data during real-time collection and transmission is a critical challenge to overcome.

3. Missing monitoring system: There is no comprehensive online energy monitoring and management system on-site, data collection coverage is incomplete, a sound measurement system has not been established, and key energy-consuming equipment is not fully monitored. Smart metering devices need to be installed based on the site conditions.

4. Lack of guidance for continuous energy reduction: Energy use analysis for high-energy-consuming equipment and production lines is incomplete, lacking comprehensive historical data support. Energy-saving measures and optimization improvements cannot be effectively implemented, and continuous optimization cannot be guaranteed during the technology development process.

1. Establish a 5-level measurement standard from factory to equipment level, supplement the installation of power meters according to the existing energy measurement instruments and standards, and integrate data from existing and newly installed energy measurement instruments and the status of major energy supply equipment into the EMS system;

2. Clarify the base's factory-level energy consumption per unit output, achieving automation and transparency in the energy measurement process;

3. Evaluate the energy efficiency of key energy-consuming equipment in public auxiliary energy stations;

4. Identify energy waste points at both the supply and consumption ends, establishing preliminary closed-loop management;

5. Establish an energy consumption indicator system down to the workshop level.

1. Energy management system coverage: Covers the entire base, enabling one-stop management from factory/workshop/production line/equipment, including air conditioning and lighting, with future expansion capabilities.

2. Energy management media scope: Electricity, water (tap water, primary pure water, secondary pure water), gas, steam, cooling/heating energy, nitrogen, compressed air, etc.

3. Energy management system integration scope: Production systems, photovoltaic systems, energy storage systems, financial systems, etc.

4. Data collection scope: Over 40,000 energy-related data points, including the installation of nearly 400 smart electricity meters, water meters, flow meters, cooling/heating meters, and data acquisition gateways.

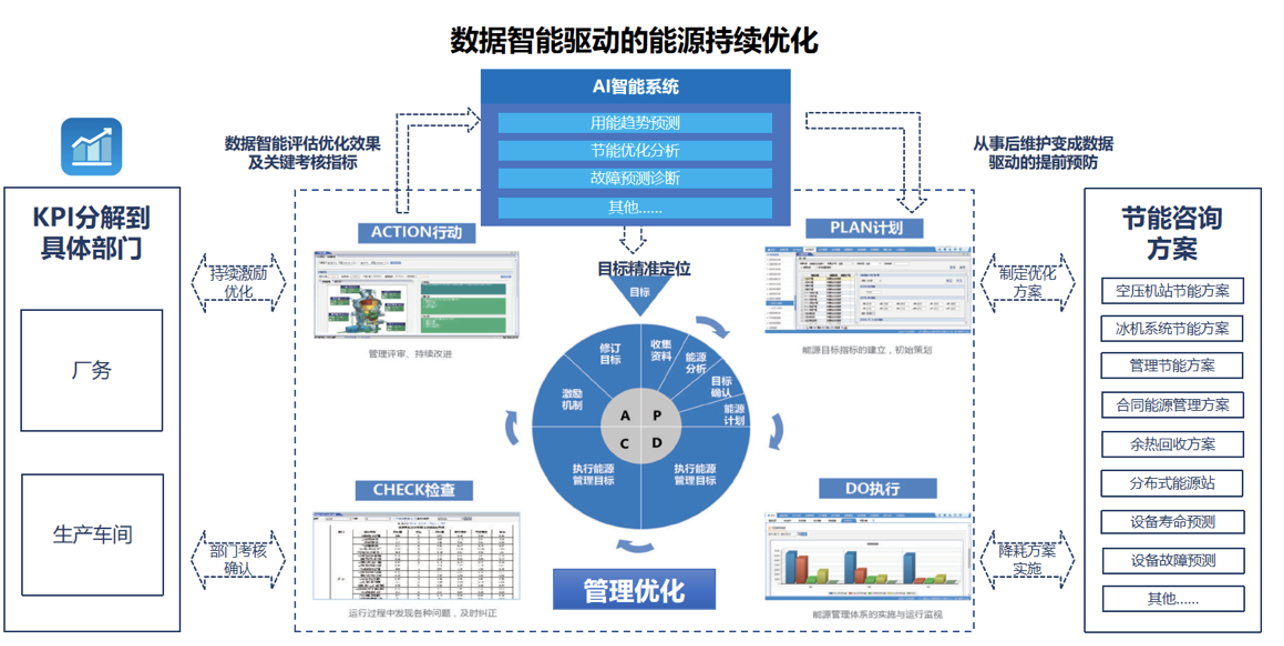

1. Unified platform, massive data application; tens of thousands of data points managed and accessed, providing a scientific basis for energy management decisions. Global visibility, efficient management; flexible multi-perspective data presentation configured as needed, empowering energy management requirements of different business units. System construction, energy-saving potential挖掘; supports enterprises in establishing measurement standards and other systems; outputs customized energy-saving solutions, helping enterprises挖掘 energy-saving potential.

2. Deployment and construction of the dual-carbon energy management system support the achievement of five key conditions for the factory; significant improvements in business operation indicators such as production efficiency, energy cost, and ecological sustainability. While enhancing the enterprise's energy digitization level, it generates millions of yuan in direct energy-saving economic benefits for the client.

3. Models for carbon emissions, emission reduction, energy consumption, and energy saving enable refined and visual management; collect carbon emission and energy consumption data, analyze data and indicators through the system, and form energy-saving and carbon reduction plans.

4. Establish a carbon inventory and accounting system, clarify carbon emissions and energy consumption of each factory, propose targeted energy-saving and carbon reduction measures, reduce costs and increase efficiency, use data-driven approaches to predict carbon emissions and energy usage trends, achieve digital green transformation for the enterprise, from low-carbon and zero-carbon to sustainable development, help build a green concept of "energy saving, low carbon, and reduced pollution," and accelerate the promotion of green manufacturing system construction. It becomes a powerful tool for optimizing energy consumption and maximizing the value of carbon assets.