How is semiconductor AMHS composed?

AMHS, short for Automated Material Handling System, refers to an automated material handling system. It specifically refers to a system that operates in a cleanroom environment, controlled and scheduled by software systems, to automatically transport and buffer materials between production line processes according to production system instructions.

AMHS offers many advantages, such as reducing material idle time, improving cleanroom utilization, increasing product yield, reducing human errors, and lowering labor costs. It is now widely used in semiconductor wafer factories, semiconductor wafer fabrication plants, and semiconductor packaging and testing plants.

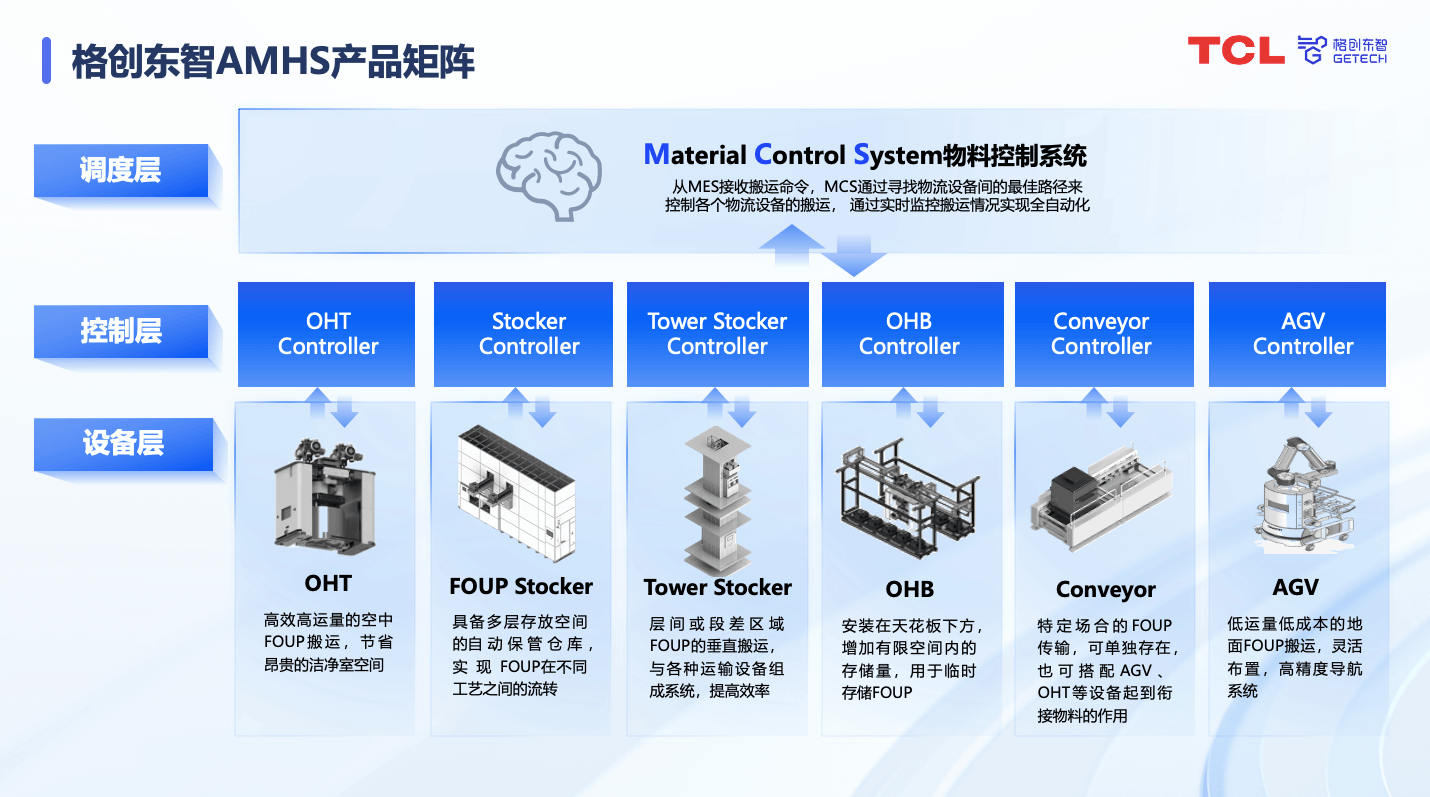

AMHS mainly consists of transport hardware equipment, storage equipment, software systems, etc.

(I) Transport Hardware Equipment

Depending on the needs of different wafer fabs, AMHS systems are mainly divided into semi-automated and fully automated solutions. Among them, 8-inch wafer fabrication plants typically adopt semi-automated solutions, involving transport hardware equipment such as AGVs (Automated Guided Vehicles), RGVs (Rail Guided Vehicles), and AMRs (Autonomous Mobile Robots) as ground transport devices. These are responsible for Intrabay line transportation, helping to improve production line automation, thereby enhancing process reliability and replacing error-prone manual handling and transportation activities.

12-inch wafer fabrication plants now mostly adopt fully automated solutions, involving transport hardware equipment such as OHT (Overhead Hoist Transport) systems. OHT can travel on overhead tracks and directly access the loading/unloading ports of storage or process equipment via belt-driven hoists. It is used within process areas as well as for inter-process or inter-factory transportation. Currently, in 12-inch wafer fabrication plants, OHT systems are widely recognized as the main transport system in FAB plants.

OHT

An automated transport device that can travel on overhead tracks and directly access the loading/unloading ports of storage or process equipment via belt-driven hoisting equipment. OHT supports global (inter-process, intra-process, inter-factory) logistics scheduling and is partially used in 8-inch wafer fabs, but widely used in 12-inch wafer fabs.

AGV/AMR/RGV

AGV refers to vehicles equipped with electromagnetic or optical automatic navigation devices that can travel along a specified navigation path;

AMR has powerful computing capabilities and can be divided into laser and visual semantic navigation, making deployment simpler;

RGV refers to rail-guided vehicles;

Ground solutions like AGV/RGV/AMR can work together; for smaller transport volumes, AGV/RGV/AMR systems are less expensive than overhead systems, but for larger volumes, they become more expensive. Additionally, AGV/RGV/AMR systems have upper limits on transport capacity, occupy cleanroom space, and are less commonly used in 12-inch wafer fabs.

Tower Lifter

Works in conjunction with the semiconductor FAB process OHT system to perform inter-floor FOUP transportation and loading functions. Some are integrated with Tower Stockers, also providing wafer storage functionality.

Conveyor

Transports wafer carriers continuously via conveyor belts, usually installed overhead and laid out according to application requirements.

(II) Storage Equipment

Storage equipment serves as temporary storage in cleanrooms, reducing the time gap between the end of one process and the start of the next. Storage equipment mainly includes storage cabinets (Stocker) for storing carriers (such as FOUP wafer carriers, Reticle boxes, etc.) and temporary storage devices (NTB) before the start of a process.

Foup Stocker Intelligent Wafer Storage Equipment

Used for storing wafer carriers during and between semiconductor production processes in cleanrooms. It can communicate with upper-level systems for automatic inventory management. Customizable to maximize space utilization based on available cleanroom space. Also supports Purge functionality.

Reticle Stocker Reticle Box Storage Equipment

Used for storing reticle boxes in semiconductor wafer fabs. It can communicate with upper-level systems for automatic inventory management and ensures reticle quality by purging with clean gas, thereby improving overall product yield in wafer fabs.

Tower Stocker Tower Storage Cabinet

Enables cross-floor transportation of wafer boxes, increases wafer box storage space, and effectively utilizes available irregular spaces around equipment.

OHB Overhead Buffer Unit

Reduces equipment idle time caused by waiting for processing or transfer by temporarily storing wafer carriers overhead.

NTB Intelligent Buffer Equipment

To match the production speed of equipment and reduce waiting time, buffer storage cabinets can be installed above equipment loading/unloading ports, adding multiple buffer layers to improve the utilization of equipment with short process times (high throughput), potentially up to nearly 100%.

(III) Software System

The software system is the core of AMHS. Through algorithm optimization, it can reduce idle transport vehicles, plan optimal routes, prevent traffic congestion, simulate and verify large-scale automated control, and achieve optimal overall efficiency.

The MCS system is the central control system of AMHS. It needs to interface with upper-level manufacturing CIM (Computer Integrated Manufacturing) semiconductor industrial software systems, including MES (Manufacturing Execution System), RTD (Real-Time Dispatching System), and EAP (Equipment Automation Programming System), to issue transport commands and upload actual transport status data. By uniformly controlling and scheduling multiple categories of material handling equipment control systems, MCS enables the overall operation of the AMHS system. Additionally, MCS can design efficient path management and automation mechanisms to resolve AMHS abnormalities.

To learn more about GTRONTEC's AMHS automated material handling system products/solutions, please call 400-600-2869 (same as WeChat number). GTRONTEC's professional team will tailor a customized solution for you.