Today's Shenzhen is not only labeled as a window for Chinese technology to the world but also a microcosm of global cutting-edge innovation achievements. From August 27 to 29, the annual benchmark in electronics, embedded, and semiconductor fields—elexcon2024 Shenzhen International Electronics Expo—grandly opened at Shenzhen Convention and Exhibition Center (Futian), creating an innovation display, one-stop procurement, and technology exchange platform for the entire semiconductor industry chain. Over 400 exhibitors and 40,000+ visitors gathered on-site, with 20+ frontier forums and 100+ industry leaders discussing market trends and capturing future technology directions.

During the exhibition, on the morning of August 29, the "Intelligent Driving Future·Industrial AI Digitalization Forum" co-hosted by China Industrial Control Network and elexcon was held in Hall 1. Leaders from top companies such as GTRONTEC, Supcon Technology, Hikrobot, Biwin Storage, OPT, Huntkey, and Inovance Technology gathered to plan for the future. At the forum, Yang Li, Marketing Director of GTRONTEC, was invited to attend and deliver a keynote speech titled "Strengthening AI+Industrial Core Technology to Create New Quality Productivity," discussing the latest R&D achievements and application trends of AI technology in the industrial field. She shared main ways of deep integration between AI technology and business, as well as successful cases of AI empowering industrial digitalization, providing actionable development paths for the audience.

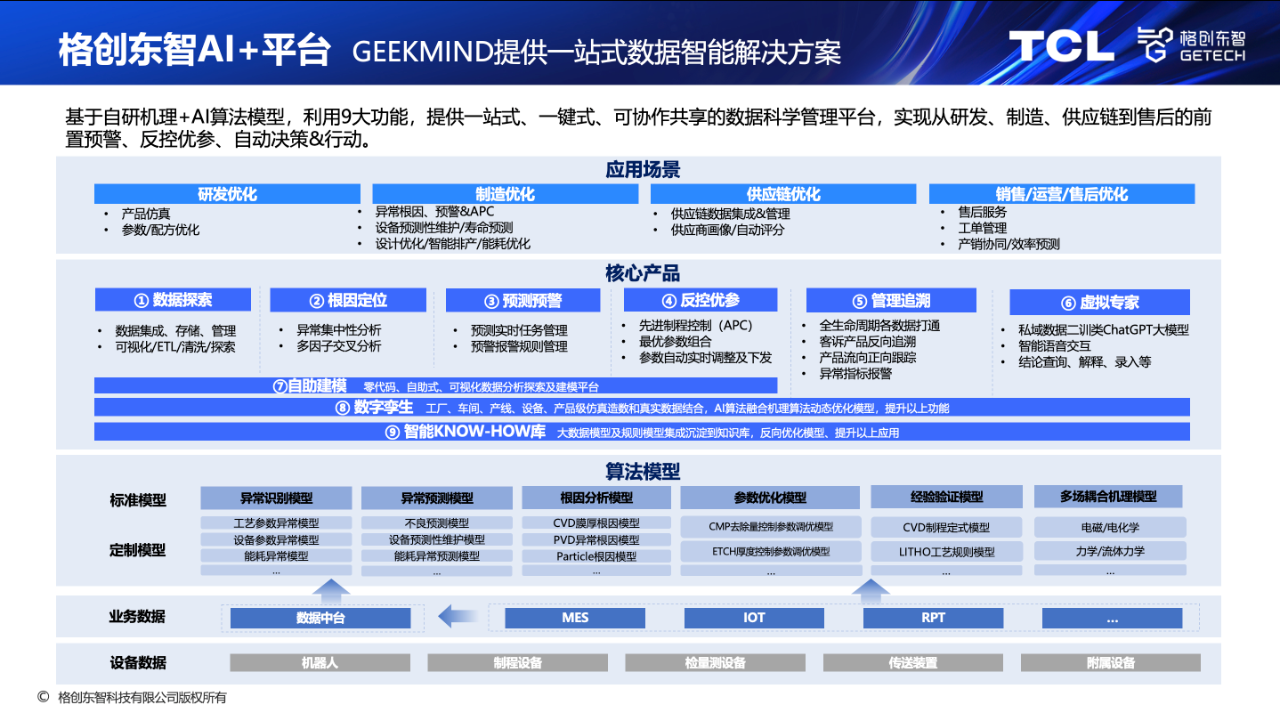

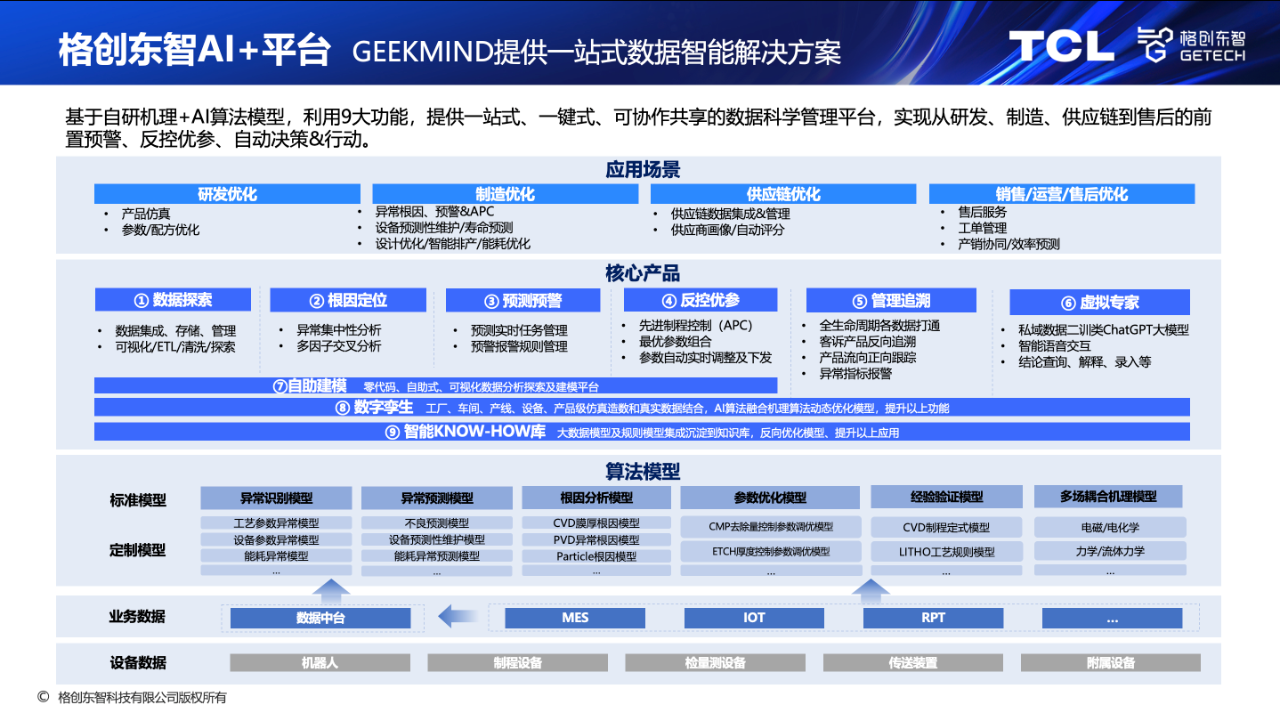

Yang Li believes that the integration of AI technology and industrial applications has gone through three stages: from a strong technology-oriented point empowerment phase, to a demand-driven phase of complex and diverse scenario empowerment, and then to a comprehensive intelligent application phase that enables overall optimization of equipment and factories, as well as decision-driven applications across entire enterprises and industry chains. AI application scenarios have deepened from exploratory points to practical implementations, driving factories toward unmanned, self-deciding management models and enabling deep empowerment across R&D, production, supply, sales, service, and management in manufacturing. The "Industrial Intelligence White Paper" (2022) led by the China Academy of Information and Communications Technology points out that production management has become a key area for industrial AI applications, accounting for over 57%, due to significant scenario demands, strong data availability, and high technology maturity. This includes quality recognition and analysis, equipment fault diagnosis and prediction, and process parameter optimization.In fact, facing the golden opportunity of AI technology普及, GTRONTEC has already positioned itself accurately, choosing to integrate into soft and hard product matrices for precise strikes. "Aiming to achieve extreme efficiency, yield, and cost for customers, and with solid AI talent reserves, GTRONTEC has rooted the 'AI in Manufacturing' development concept in rich manufacturing soil. In complex scenarios such as R&D optimization, manufacturing optimization, supply chain optimization, and sales operation after-sales optimization, we collect multi-source heterogeneous data, build AI algorithm models, and develop flagship AI products for functions like data exploration, root cause定位, prediction and warning, reverse control and parameter optimization, and management tracing. Named products include Tianshu AI Defect Detection System, Octopus Brain Industrial AI Large Model, and Data Intelligence Large Model Assistant, helping highly automated manufacturing improve production efficiency and product quality, reduce energy consumption and carbon emissions, achieve predictive system risk management, drive intelligent decision-making, and optimize supply chains," Yang Li added.

In terms of specific customer service practices, Yang Li stated, "GTRONTEC's AI applications have covered TCL Group's engineering efficiency improvement, internal efficiency, manufacturing, and smart terminal areas. Taking TCL CSOT as an example, over 10 types of AI applications have been built on its five digital platforms: smart R&D platform, integrated supply chain platform, smart manufacturing platform, integrated finance platform, and ERP information platform. In 2024, AI helped its LCD simulation project generate收益 of over 28 million yuan. The core factors include sufficient AI talent and R&D reserves, deep industry know-how, complete product layout, and a business ecosystem for win-win value across the industry chain."

The change brought by AI to the future is not only innovative emerging technology but also providing more reliable agile event response guarantees for autonomous decision-making and flexible digitalization in smart manufacturing fields. Yang Li pointed out that besides serving TCL Group internally, GTRONTEC's AI product matrix has empowered industries such as chips, display,光伏, lithium battery, electronics, and automotive. In a semiconductor chip customer service practice, GTRONTEC provided AI services like root cause analysis and virtual measurement in product quality inspection, reducing loss costs by 12%. Behind this, the AI technology revolution has broken service boundaries, offering manufacturing enterprises more accurate, intelligent, and proactive capabilities to solve visible and invisible problems, injecting new vitality into smart manufacturing development.Seizing opportunities and opening new局面. In recent years, the deep integration of AI technology and the industrial field is leading an unprecedented smart manufacturing revolution. The application of artificial intelligence technology not only improves production efficiency but also greatly promotes the intelligent and personalized development of industrial products. Under the new competitive landscape where AI technology continuously breaks through manufacturing development boundaries, GTRONTEC will innovate in the core capabilities, resources, and implementation practices required for 'AI-driven decision-making,' continuously diving into the deep waters of smart manufacturing to助力 high-quality development of manufacturing.