Semiconductor AMHS Technology Development Trends

The origin of AMHS can be traced back to the 1980s. To improve production efficiency and reduce wafer transfer time between different equipment, semiconductor manufacturers began developing automated material handling systems. This system can automatically transport wafers from storage locations to processing equipment and then return the processed wafers back to storage.

As is well known, semiconductor manufacturing involves numerous and complex processes, expensive equipment, high requirements for the operating environment and material handling, and high sensitivity to equipment efficiency and product yield. The emergence of automated material handling systems has significantly improved the production efficiency and yield of semiconductor manufacturing while reducing labor costs and human errors. With the development of the semiconductor industry, AMHS has gradually been widely adopted in semiconductor fabs worldwide. With the help of AMHS, semiconductor manufacturers can better achieve automated production and quality control, improving production efficiency and product yield.

At the same time, with the development of emerging technologies, AMHS also exhibits the following trends.

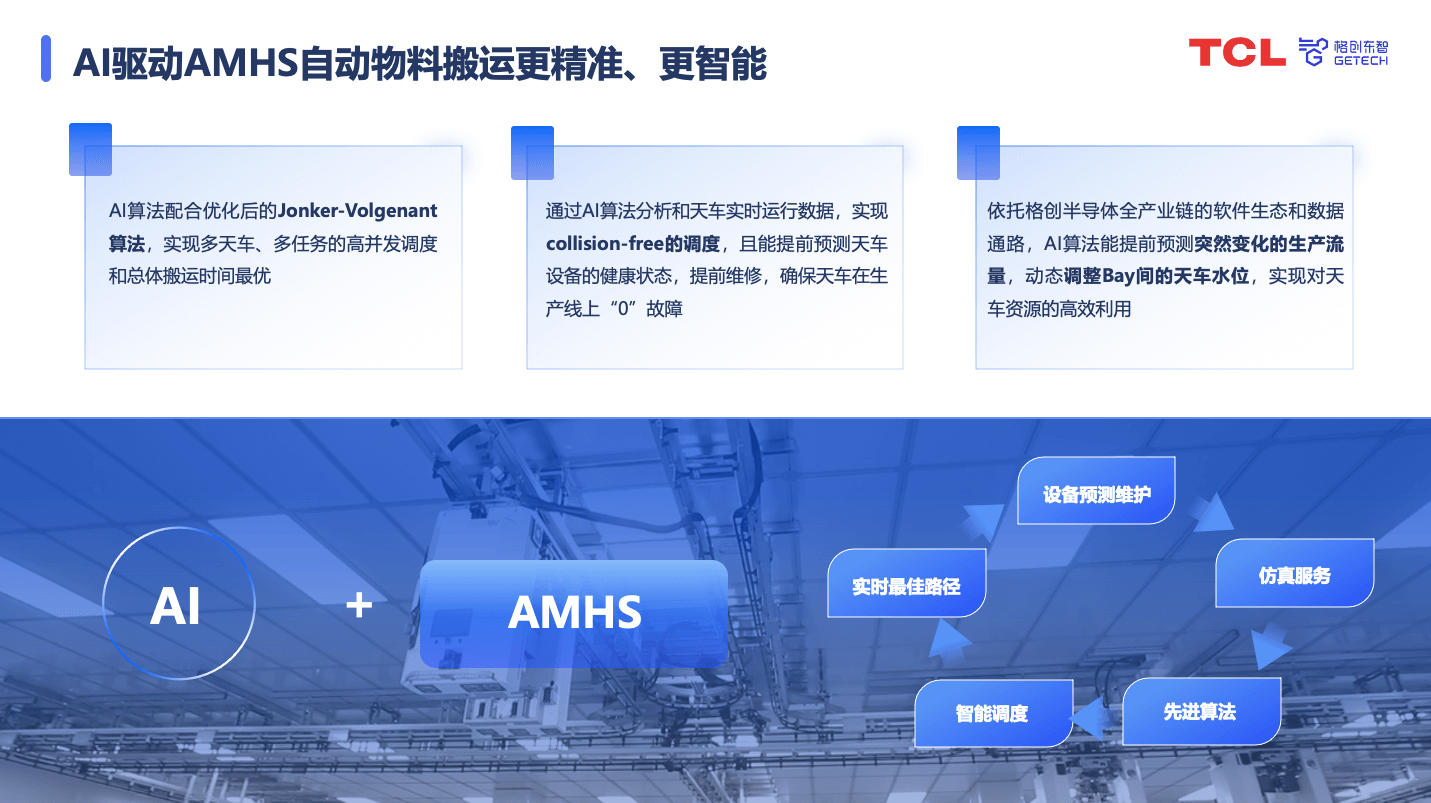

(1) AI Empowerment Further Optimizes Material Handling Processes

With the development of AI deep learning algorithms and the rapid iteration of large models, AI algorithms or industrial large models customized for specific fields are expected to be embedded in terminal applications in the future. Introducing AI into software systems helps AMHS systems enhance capabilities such as customized services, human-machine interaction, adaptive control, intelligent analysis and decision-making, fault prediction and maintenance, thereby further optimizing the overall material handling process, improving equipment utilization and product yield, and helping customers reduce costs and increase efficiency.

Customized Services

AI can assist engineers in simulation and optimization design based on extensive experimental data and experiential knowledge, enabling faster development of energy-efficient and structurally reasonable customized AMHS solutions. Through personalized customization, it better meets customer needs and enhances market competitiveness.

Human-Machine Interaction

Through natural language processing technology, AI will significantly improve human-machine interaction, allowing operators to command and monitor AMHS equipment operations using more intuitive and natural language commands.

Adaptive Control

AI will improve path planning and obstacle avoidance strategies for mobile equipment such as AGVs, enabling more precise autonomous navigation in complex production environments. It will also help equipment quickly adapt to different working conditions or sudden changes, enhancing the overall system's stability and flexibility.

Intelligent Analysis and Decision-Making

AI will provide more precise scheduling strategies for AMHS equipment through neural network training, processing, and analysis of massive data, minimizing idle equipment and preventing traffic congestion.

Fault Prediction and Maintenance

Using AI for predictive maintenance, potential fault risks in AMHS systems can be identified in advance through learning and pattern recognition of historical operational data, reducing unplanned downtime and maintenance costs.

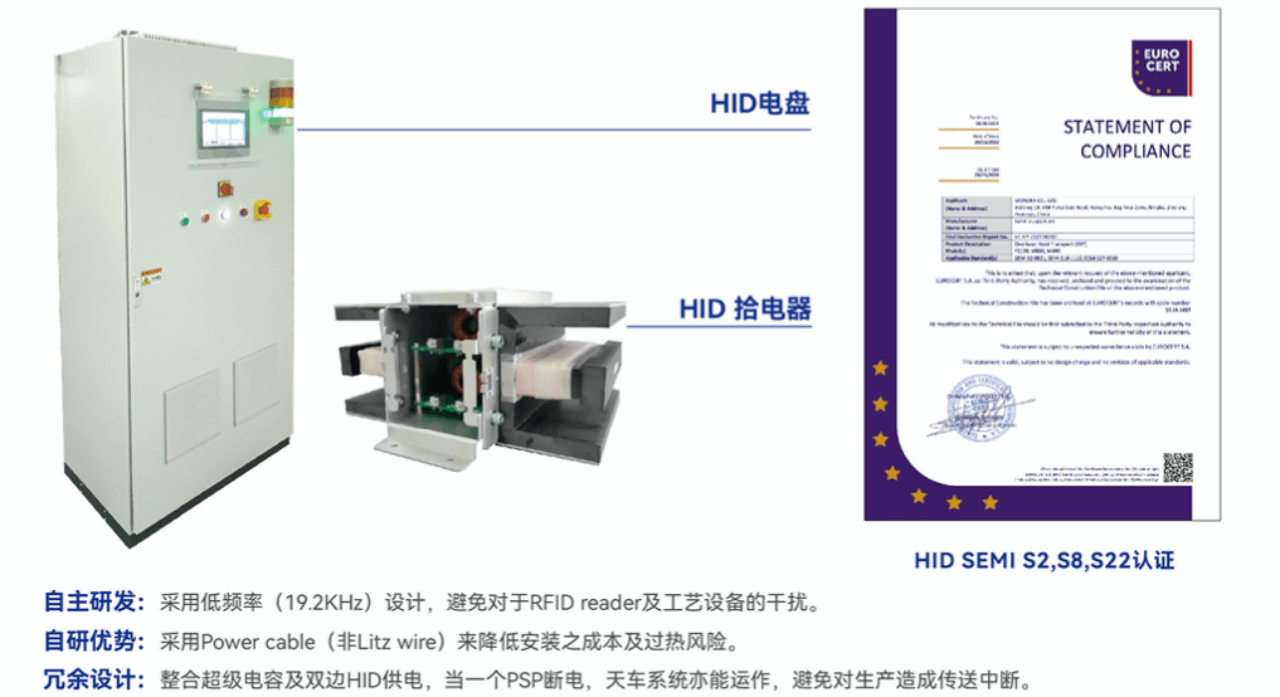

(2) HID Wireless Power Supply Technology Will Further Penetrate AMHS

In the AMHS industry, material handling overhead hoist transport and control solutions based on wireless power supply have rapidly penetrated various wafer fabs in recent years due to their convenience and power savings, gradually replacing wired power supply solutions. Compared with traditional wired power supply, wireless power supply technology allows electrical equipment to operate without connecting to power cords and without distance limitations, not only avoiding line waste and power failure risks but also improving the convenience, reliability, and safety of equipment use.

The contactless power supply monorail system (HID) mainly consists of four parts:

1. The HID power panel converts commercial power into a frequency suitable for contactless power supply and then delivers power to the control cable.

2. It controls the special cable laid along the track of the moving device, generating a magnetic field around the cable to achieve efficient power transmission to the moving device.

3. The pickup coil is wound opposite the control cable on the moving device to receive power from the magnetic field of the control cable.

4. The power receiving unit stabilizes the power received by the pickup coil and provides high-quality power to inverters and servo drivers.

GTRONTEC's self-developed HID has the following features:

Self-developed: Uses low frequency (19.2KHz) design to avoid interference with RFID readers and process equipment.

Self-developed advantage: Uses power cables (not Litz wires) to reduce installation costs and overheating risks.

Redundant design: Integrates supercapacitors and dual HID power supply. If one PSP loses power, the OHT can still operate, avoiding production interruptions.

To learn more about GTRONTEC's AMHS automated material handling system products/solutions, please call 400-600-2869 (also available on WeChat). GTRONTEC's professional team will tailor a customized solution for you.