GTRONTEC Tianshu AI Platform 3.0 Released, Building an Innovative Industrial Intelligent Inspection Model Platform, Empowering Comprehensive AI Application Talent Cultivation in Enterprises--C

2024-09-13

Recently, GTRONTEC officially released its self-developed Tianshu AI Platform 3.0, widely applied in intelligent manufacturing fields such as semiconductors, photovoltaics, new energy, automotive, and 3C electronics. The platform integrates various cutting-edge deep learning algorithms to achieve accurate identification, automatic classification, and error correction for quality defects in multi-process production scenarios, meeting manufacturing enterprises' needs for plant-wide intelligent inspection through a standardized AI centralized detection platform. The platform has further upgraded its intelligent base, AI inspection model, visual editing, and other functions, enabling rapid expansion to new scenarios, usability after just 3 days of training, and cultivating comprehensive industrial AI application talent for clients.Tianshu AI Platform 3.0 Leads the Industry with Key Technologies01 Driven by AI Inspection Model, More Accurate Defect Identification and AnalysisBased on a full data lifecycle learning framework, Tianshu AI Platform 3.0 has developed an industrial quality inspection model solution integrating network structure, self-supervision, and active learning, forming a closed-loop service capability of "data-model-effect improvement" to continuously enhance production line model performance. It uses one set of technology to solve defect detection tasks for different products and scenarios, effectively improving development efficiency.

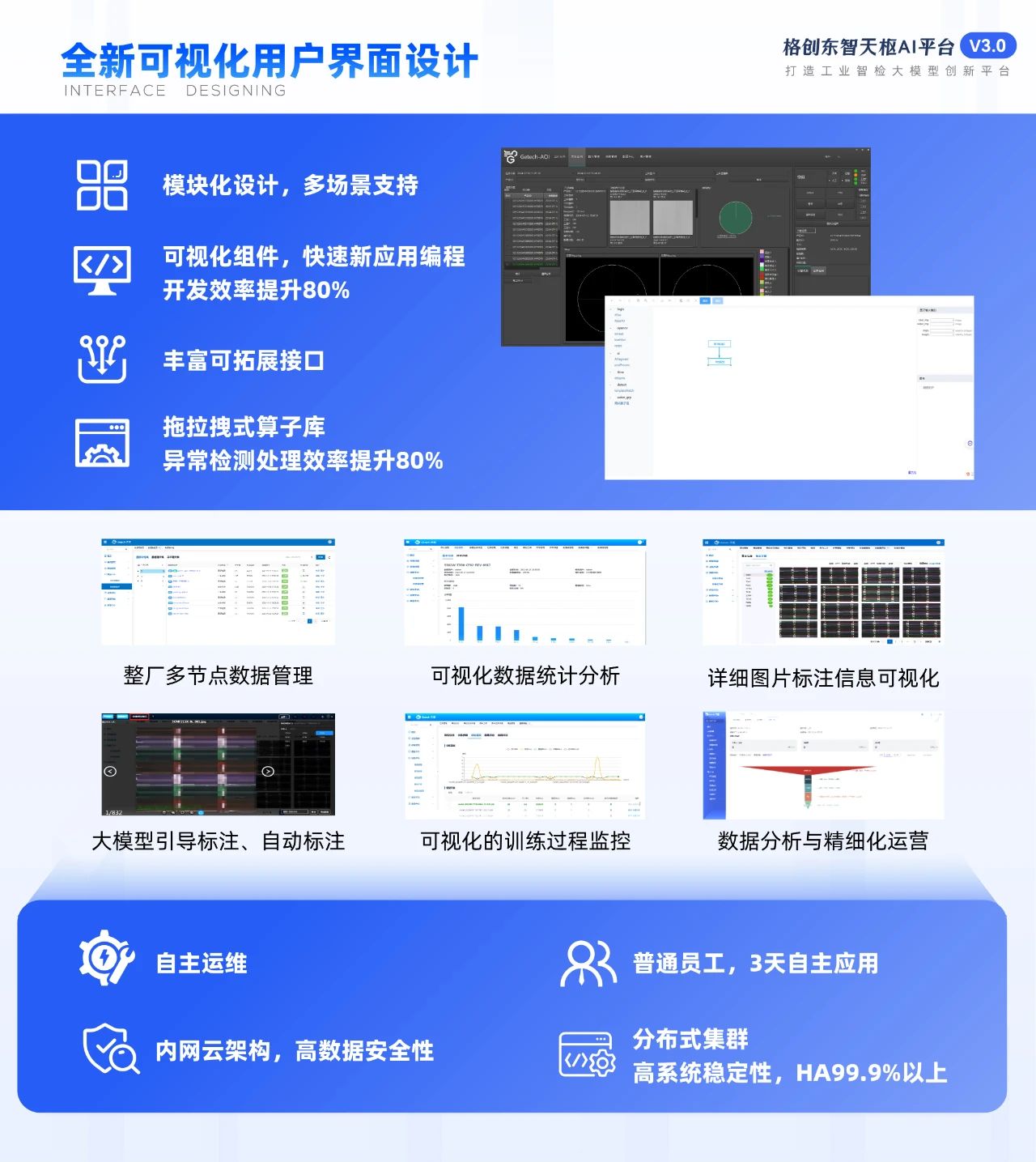

02 Equipped with K8S Computing Resource Scheduling, Maximizing Resource UtilizationTianshu AI Platform 3.0 integrates technologies like K8S task auto-scheduling, GPU resource pooling, and distributed storage to complete the AI management base. The self-developed network architecture effectively reduces AI learning data volume, solving the problem of rapid product model changes.03 Image + Feature Space Learning Method, Quickly Identifying Personalized Defect IssuesUsing image space reconstruction and feature embedding methods, it addresses industry challenges like occasional, low-frequency 'others' class defects in industrial inspection.04 Distillation Architecture Refines Multi-Scenario Small Applications, No Hiding for Complex DefectsThe intelligent distillation architecture enables adaptation of large models to small applications, greatly reducing resource consumption and achieving full-scenario application.Faster model migration and generalization capabilities allow one set of technology to solve defect detection tasks for different products and scenarios, effectively improving development efficiency.05 Visual Editing Module, Building a Quality Inspection Cockpit for Decision DrivingTianshu AI Platform 3.0 also developed a visual programming module, simplifying the model development process into intuitive drag-and-drop operations, enabling non-AI expert IT staff to easily develop and optimize AI models.

High Stability + High Performance + High Reliability + Easy Expansion Innovation Technology Architecture Accelerates Industrial Quality Revolution

Tianshu AI Platform 3.0 is an innovative technology architecture integrating high stability, high performance, high reliability, and easy expandability. It demonstrates excellent technical strength and application value across multiple fields, providing users with outstanding intelligent services and reliable support for future technology development and business needs with continuous optimization capabilities.

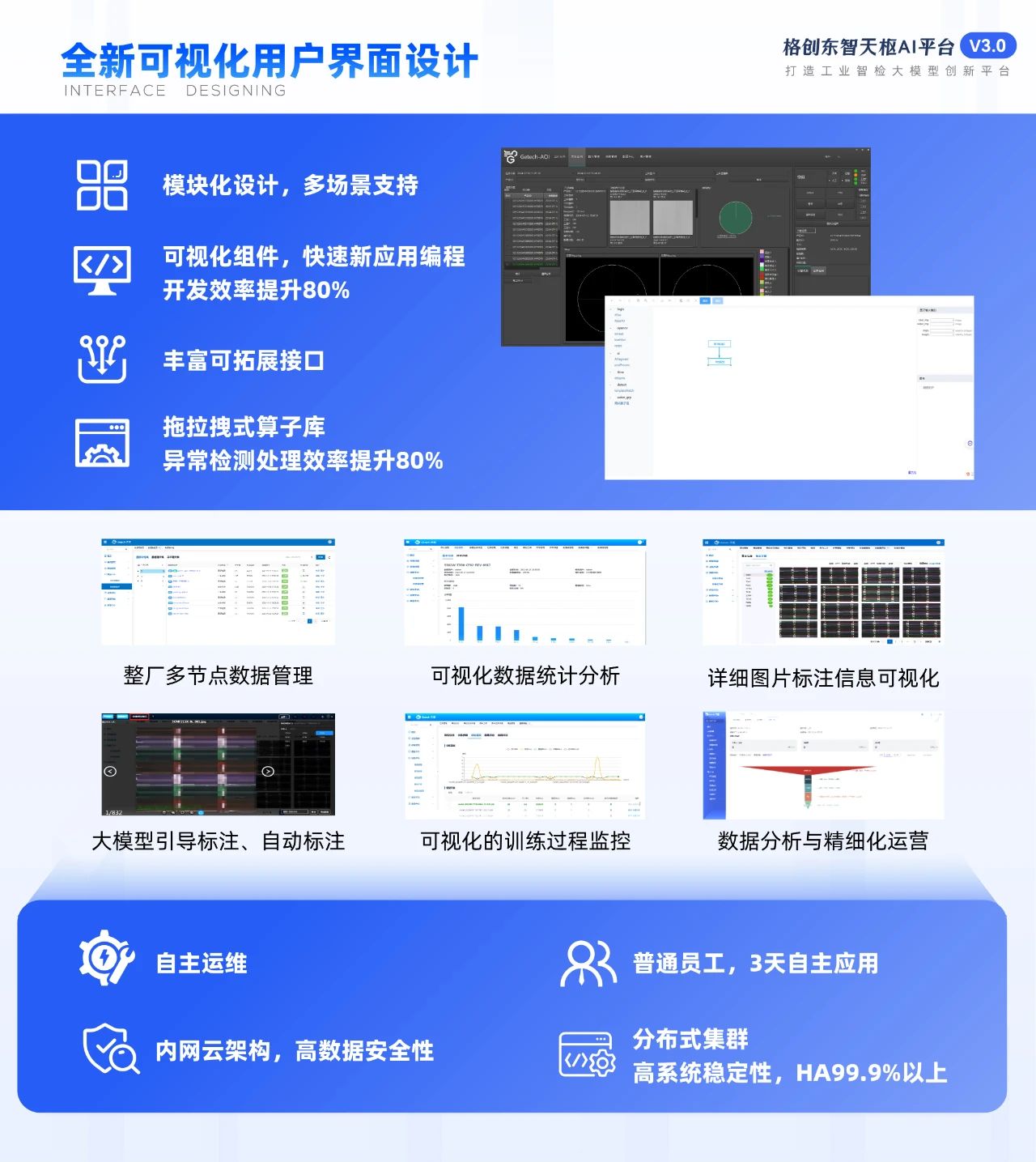

Solid Technical Foundation: The system uses advanced technologies like cloud platforms, big data, machine learning, and AI, validated and optimized over time, providing a solid foundation for stable operation.Centralized Data Processing: The system processes various data through a unified platform, breaking traditional information silos, improving data accuracy and consistency, thus enhancing system stability.Real-Time Monitoring and Fault预警: The system can monitor the status of all devices in real-time,及时发现并预警潜在故障, providing timely and accurate information for maintenance personnel to ensure continuous stable operation.Efficient Data Processing: The system has strong data processing capabilities, quickly responding to various business needs and providing efficient data processing services.Improved Computing Speed: Tianshu's unique AI job scheduling achieves全方位提升 in computing speed, greatly enhancing system efficiency.Multiple Security Measures: Tianshu system emphasizes security in design, adopting multiple security measures to ensure data security and business continuity.Practically Proven: In practical applications across multiple fields, Tianshu system has demonstrated extremely high reliability and stability, widely recognized by users.Modular Design: Tianshu system adopts a modular design concept, with relatively independent functional modules, facilitating subsequent maintenance and upgrades.Standardized Interfaces: The system provides various data interfaces and standardized data access protocols, supporting different专业设备 to integrate data in various ways, reducing the difficulty and cost of device access.Flexible Configuration: Users can flexibly configure system functions and resources according to actual needs, achieving personalized customization and快速响应 to changes in business requirements.New Visual User Interface Design Brings New Ways of Quality ControlTianshu AI Platform 3.0 provides new UI components, significantly improving user experience by optimizing operational interactions. The new UI design makes the interface more intuitive and user-friendly, further enhancing user工作效率 and system operation smoothness.

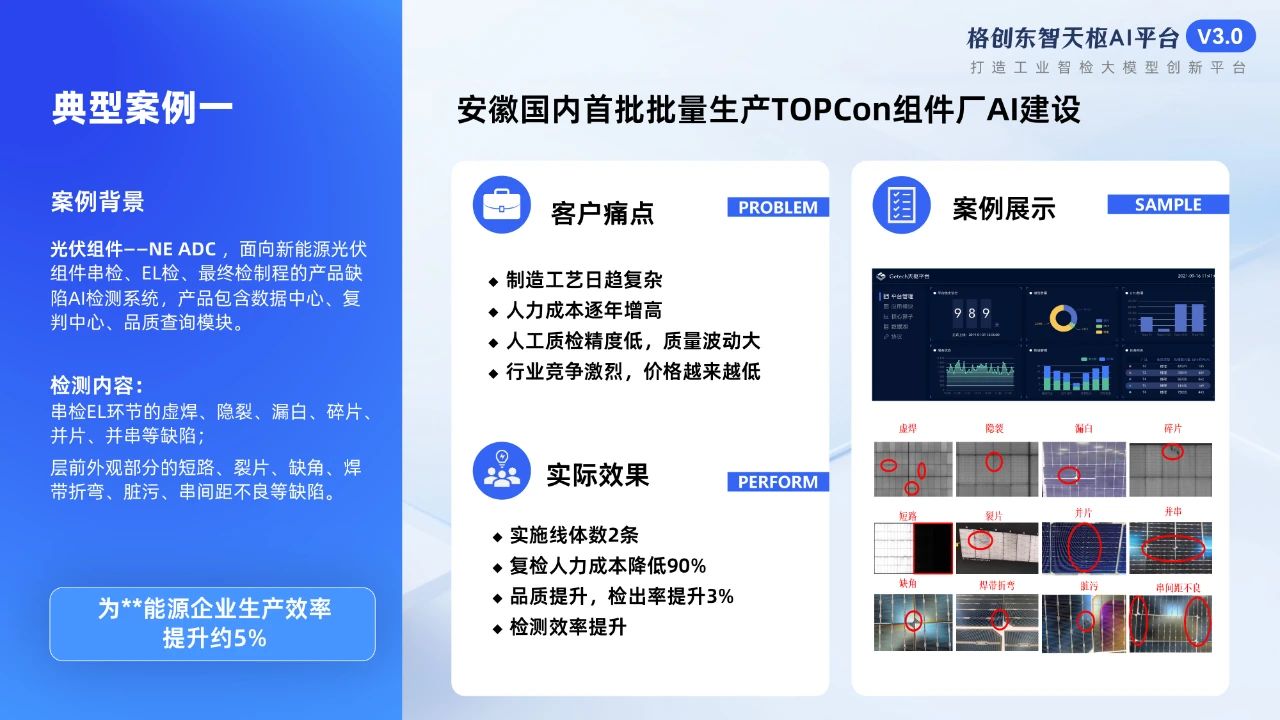

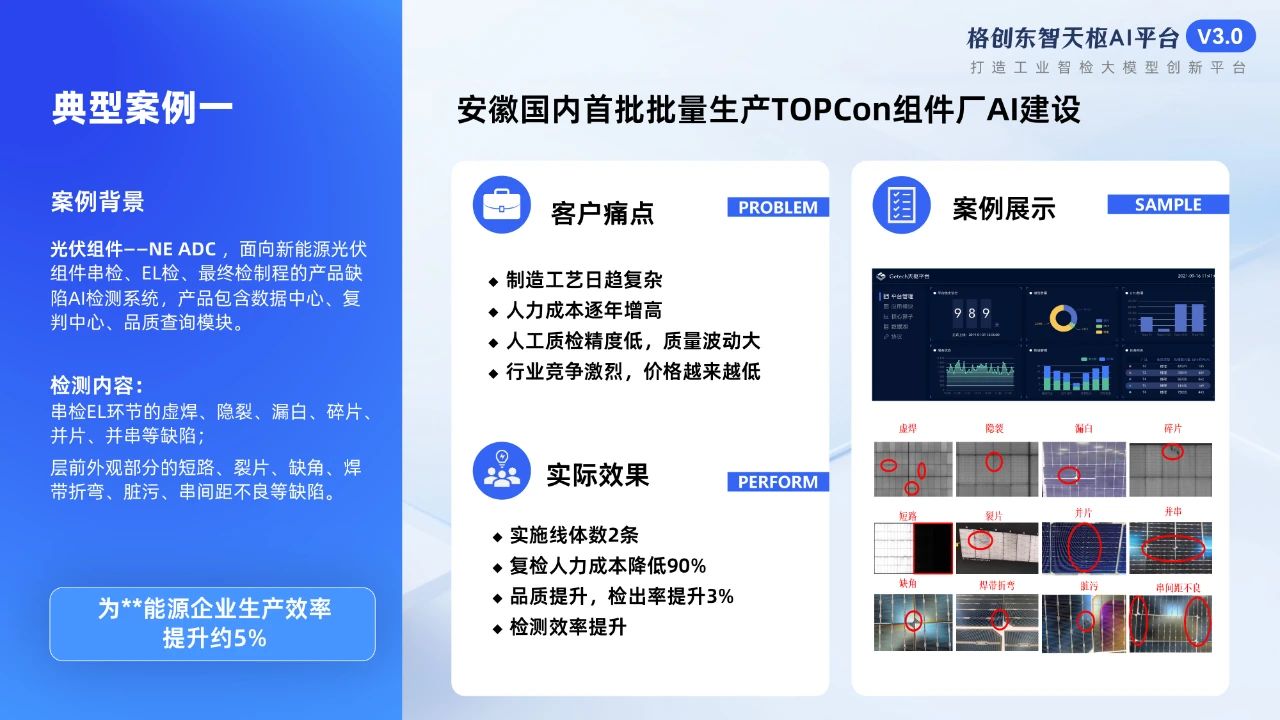

Benchmarking Typical Application Scenarios, Finding the Accurate "Out-of-the-Box" ApproachScenario One TOPCon Component Mass Production Plant AI Platform Construction, Quality Detection Rate Increased by 3%, Labor Costs Reduced by 90%

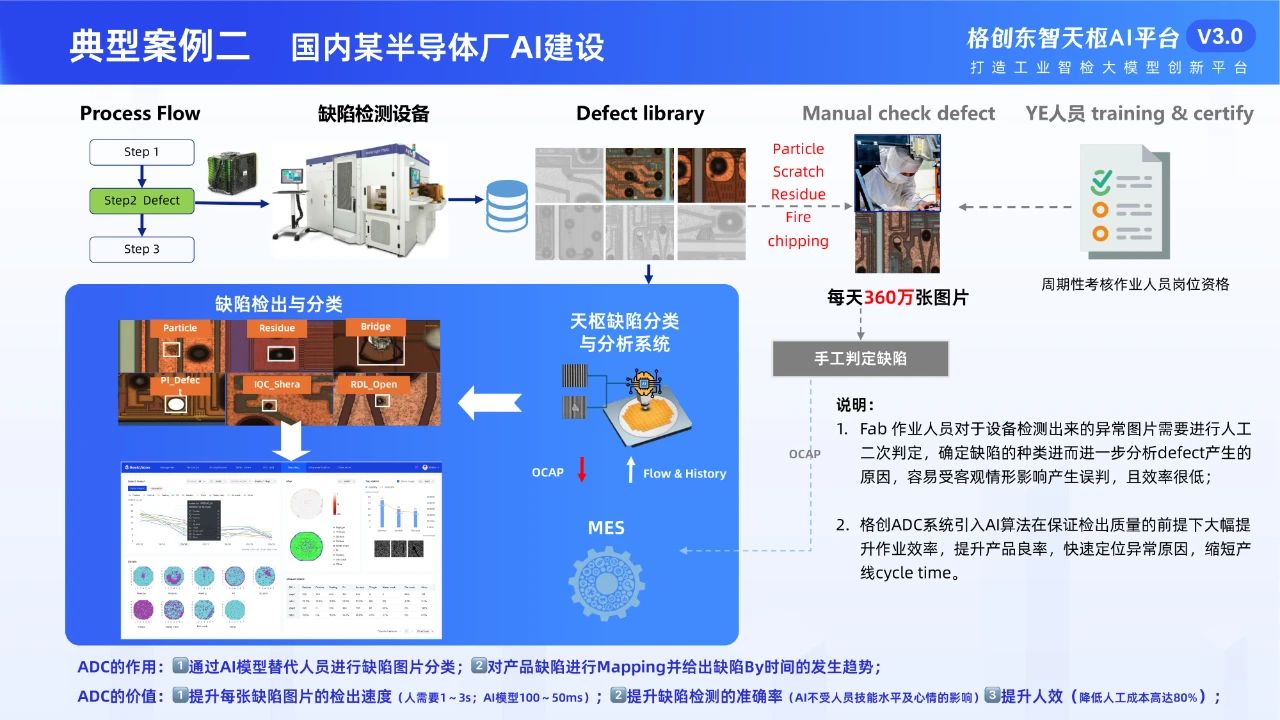

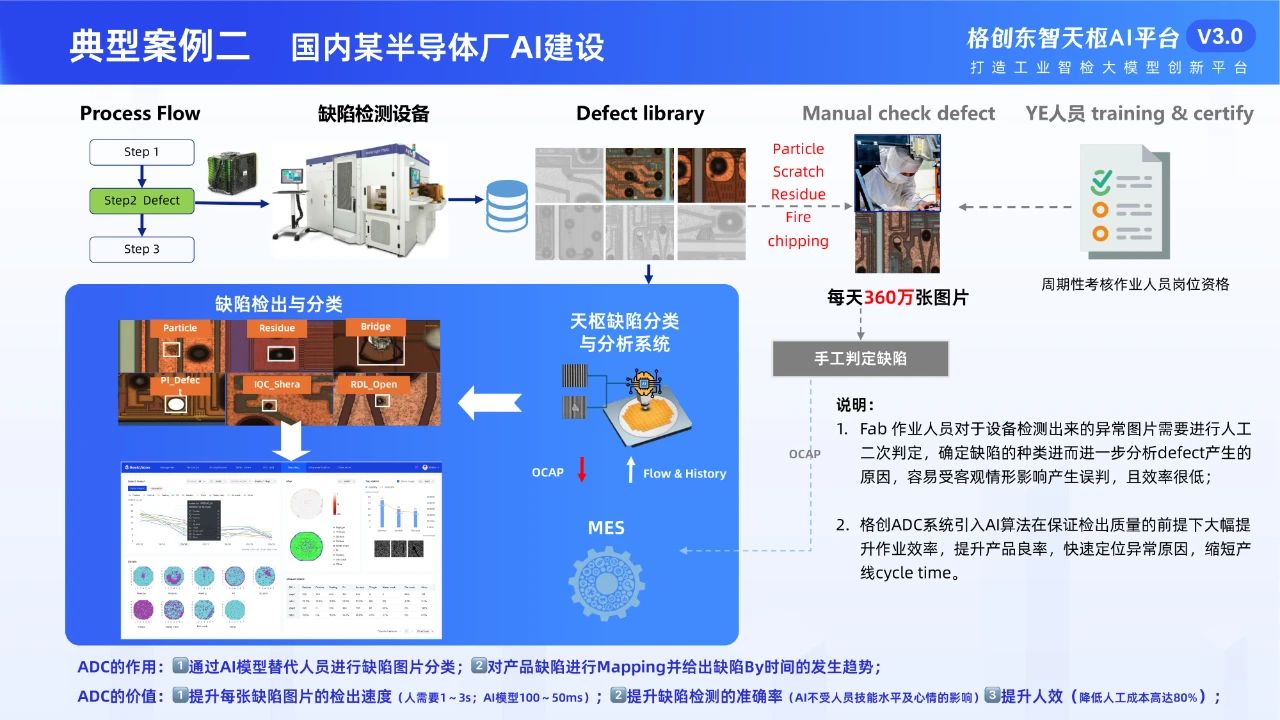

Scenario Two Semiconductor FAB Plant AI Platform Construction, Significantly Improving Quality Detection Rate, Shortening Product Cycle Time