GTRONTEC AMHS, Opening a New Chapter in Pan-Semiconductor Efficiency Improvement

2024-10-11

Recently, GTRONTEC successfully delivered the first Stocker wafer storage vertical warehouse in just 15 days, helping a leading 12-inch wafer fab meet the demand for efficient automated material storage expansion. This achievement is not only a step forward for the company's business but also a significant breakthrough in the development of domestic AMHS technology.The FAB plant material storage Stocker is designed for the storage and handling of various carriers such as FOUP/SMIF Pod. It offers customized services based on the customer's on-site space and other specific needs to maximize the utilization of FAB plant space. Equipped with an intelligent storage management system, the Stocker plays a crucial role in reducing outbound time and improving handling efficiency in FAB plants, providing essential support for achieving Fully Auto operations. GTRONTEC's self-developed Stocker product line includes not only FOUP Stocker but also the domestically first-developed Tower Stocker, which has been delivered to customers since 2022, fully covering storage usage scenarios for 8-inch and 12-inch cassettes.

For FAB plant Stockers, storage is only a basic requirement.Real-time communication with the AMHS upper system, achieving automatic MCS material management, reducing handling congestion, and ensuring efficient machine scheduling are the advanced pursuits of customers.

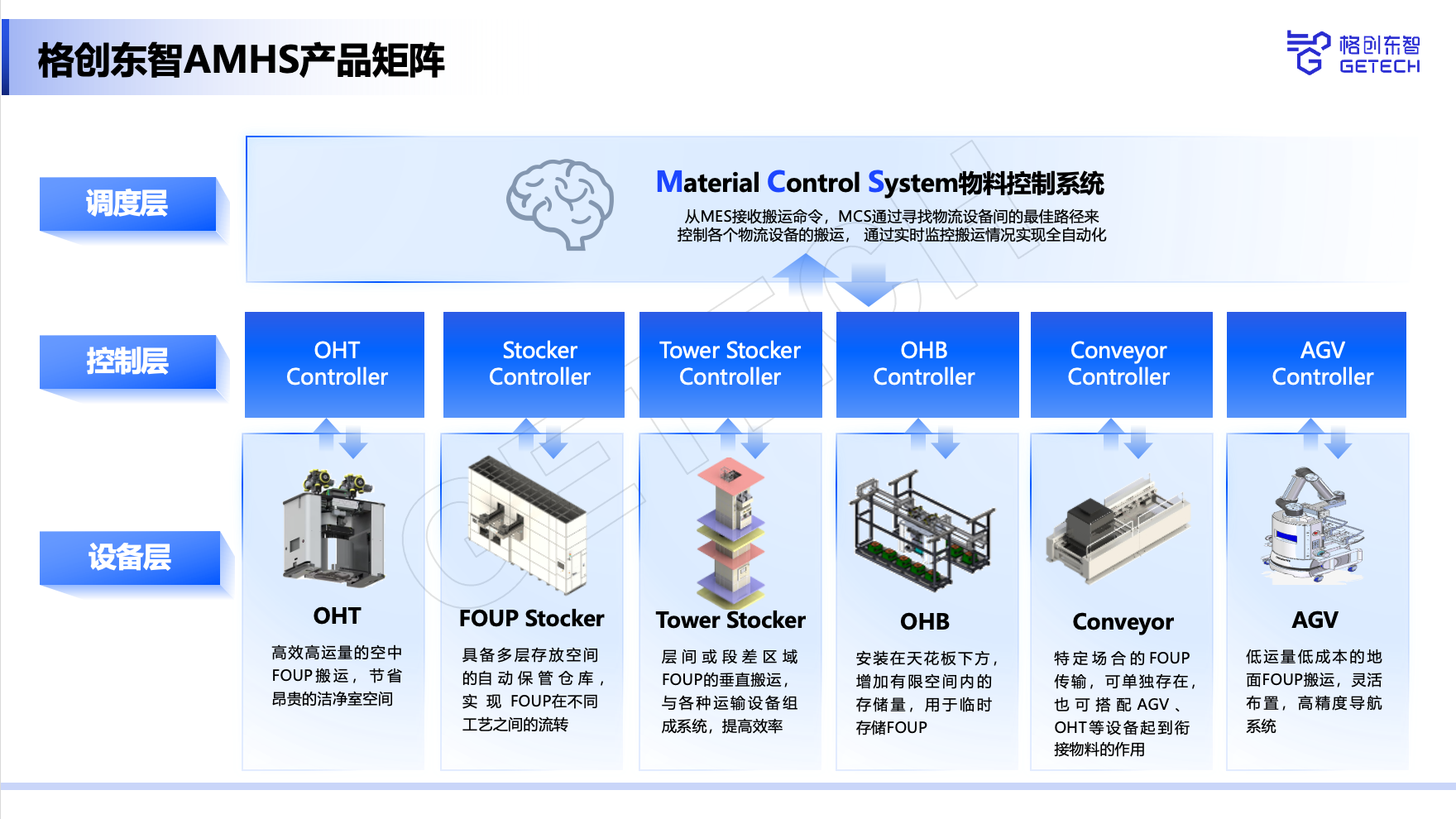

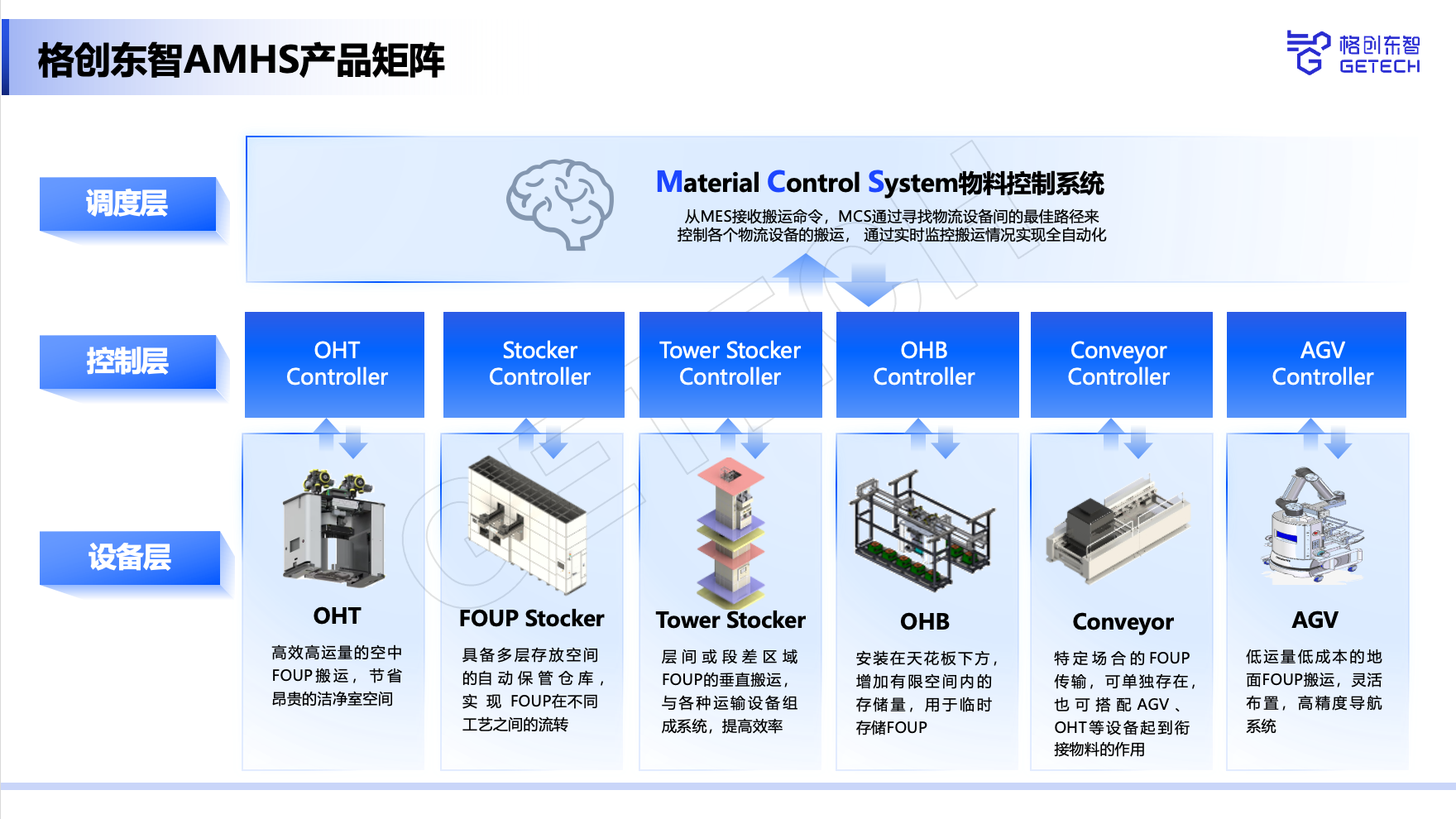

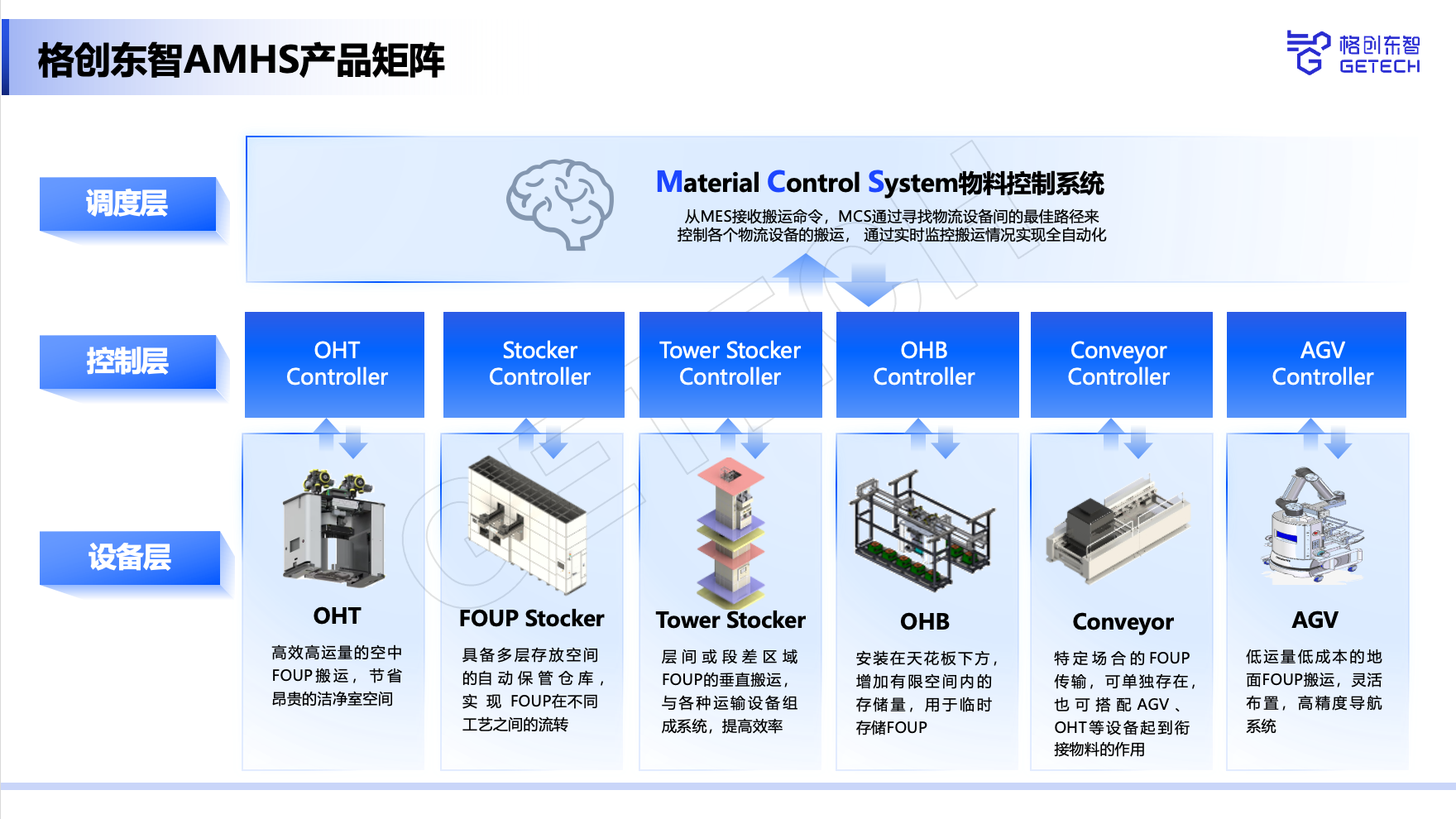

As is well known, AMHS mainly consists of OHT overhead handling vehicles, Stocker wafer storage vertical warehouses, and software systems such as MCS/OHTC/STKC. OHT, as the most technically complex part, has varying demands in different FAB plants. The current mainstream material handling systems in 8-inch wafer fabs have relatively low handling efficiency due to fewer types and numbers of track branches. In contrast, 12-inch wafer fabs have extremely complex track layouts, including various branches, curved tracks, high-low tracks, and lifting devices. Due to increased production capacity, higher handling speed requirements necessitate more sensors, lidars, and other products with control systems. Meanwhile, OHT scheduling algorithms are more complex, and software iteration speed must keep up with customer needs. In this regard, the AMHS product manager at GTRONTEC pointed out that during Demo Line validations in different wafer fabs, the company has already considered market demands in advance and has continuously carried out performance, stability, and software functionality aspects extensive optimization and iteration work.To better help customers succeed, GTRONTEC continuously iterates its three core capabilities: "AI + industrial software + equipment intelligence," accelerating the integration of hardware and software capabilities.The company's self-developed OHT overhead crane, covers front-end 6-inch/8-inch SMIF Pod and 12-inch FOUP, back-end Magazine, meeting the carrier handling needs of factories in different processes; and provides various track modules to meet the complex Layout requirements of 12-inch wafer fabs; in terms of efficient collaboration between OHT equipment and personnel, through 11 types of safety protection sensors, it effectively identifies and automatically warns about operating conditions such as crane speed, obstacle avoidance, collision detection, cassette breakage, lifting晃动, wafer drop, and cassette position, creating an efficient automated, clean, and low-vibration logistics automatic handling method.Additionally, GTRONTEC combines self-developed achievements in equipment, software, algorithms, and applications to help customers succeed, providing full-stack AMHS products at the scheduling, control, and equipment layers, unleashing the unlimited potential of customer production.

In this regard, the AMHS product manager at GTRONTEC pointed out that during Demo Line validations in different wafer fabs, the company has already considered market demands in advance and has continuously carried out performance, stability, and software functionality aspects extensive optimization and iteration work.To better help customers succeed, GTRONTEC continuously iterates its three core capabilities: "AI + industrial software + equipment intelligence," accelerating the integration of hardware and software capabilities.The company's self-developed OHT overhead crane, covers front-end 6-inch/8-inch SMIF Pod and 12-inch FOUP, back-end Magazine, meeting the carrier handling needs of factories in different processes; and provides various track modules to meet the complex Layout requirements of 12-inch wafer fabs; in terms of efficient collaboration between OHT equipment and personnel, through 11 types of safety protection sensors, it effectively identifies and automatically warns about operating conditions such as crane speed, obstacle avoidance, collision detection, cassette breakage, lifting晃动, wafer drop, and cassette position, creating an efficient automated, clean, and low-vibration logistics automatic handling method.Additionally, GTRONTEC combines self-developed achievements in equipment, software, algorithms, and applications to help customers succeed, providing full-stack AMHS products at the scheduling, control, and equipment layers, unleashing the unlimited potential of customer production.

According to Moore's Law, the semiconductor industry shows a development trend of fast product upgrades, continuous performance improvement, declining costs, and shrinking processes. The technological development direction of AMHS is closely related to the future trend of the semiconductor industry. As a pioneer enterprise insisting on self-developing the entire set of AMHS automation software and hardware, equipment components, and transformation solutions, GTRONTEC firmly believes that only self-developed software and hardware can handle all uncertainties in high-tempo production. Although the path of self-development is full of challenges, it has long-term value in accompanying customers throughout their lifecycle growth and meeting their flexible upgrade needs at different development stages.

According to Moore's Law, the semiconductor industry shows a development trend of fast product upgrades, continuous performance improvement, declining costs, and shrinking processes. The technological development direction of AMHS is closely related to the future trend of the semiconductor industry. As a pioneer enterprise insisting on self-developing the entire set of AMHS automation software and hardware, equipment components, and transformation solutions, GTRONTEC firmly believes that only self-developed software and hardware can handle all uncertainties in high-tempo production. Although the path of self-development is full of challenges, it has long-term value in accompanying customers throughout their lifecycle growth and meeting their flexible upgrade needs at different development stages.

Currently, GTRONTEC has clear goals and paths in the AMHS field. As a leading enterprise in domestic AMHS self-development, we will continue to invest in the refinement of products, improvement of system performance and stability, and accelerate the realization of AMHS localization substitution goals.