GTRONTEC wins the first SEMiBAY Most Promising Development Award, leading semiconductor digital intelligence

2024-10-16

Wind rises from the sea, tide comes from the bay area. From October 16-18, the first SEMiBAY Bay Area Semiconductor Industry Ecosystem Expo was held at Shenzhen Convention & Exhibition Center (Futian), attracting over 400 leading companies from the global semiconductor industry chain and over 30,000 professional visitors. The expo concurrently hosted over 20 semiconductor professional forums, covering core industry topics and hot technology applications such as wafer manufacturing processes, Chiplet, advanced packaging, compound semiconductors, automotive semiconductors, HBM, AI chips, and high-performance computing. It gathered over 100 semiconductor industry leaders, technical experts, top scholars, and elite enterprises from home and abroad to comprehensively define and deeply discuss the trends and potential opportunities in the semiconductor industry.With its technological leadership and deep empowerment practices in the semiconductor industry, GTRONTEC won the Most Promising Development Award at the honors ceremony. Meanwhile, the company's Deputy General Manager of the Semiconductor Business DepartmentMa Wei appeared with global wafer foundries, IDMs, packaging and testing companies, and technical experts at the Wafer Manufacturing Process and Management Innovation Forum held during the event, providing comprehensive digital transformation solutions for semiconductor factory renovations and new plant construction from a forward-looking perspective and innovative ideas.

There are always heroes in the semiconductor industry, but not all heroes can hold the throne. Ma Wei pointed out that facing challenges such as sharp fluctuations in market demand, complexity of production processes, stringent quality requirements, and rapid technological iteration, semiconductor companies urgently need digital transformation to improve production efficiency and product quality.When discussing the benefits of semiconductor digital factory construction, Ma Wei emphasized that through equipment intelligence, management upgrades, process innovation, and quality system improvements, companies can use big data analysis and AI technology to monitor processes in real-time, quickly resolve production bottlenecks, and thus enhance product performance. Additionally, with the introduction of new technologies, AI and large model platforms can accelerate the simulation and verification of new processes, shorten introduction time, and improve market competitiveness.

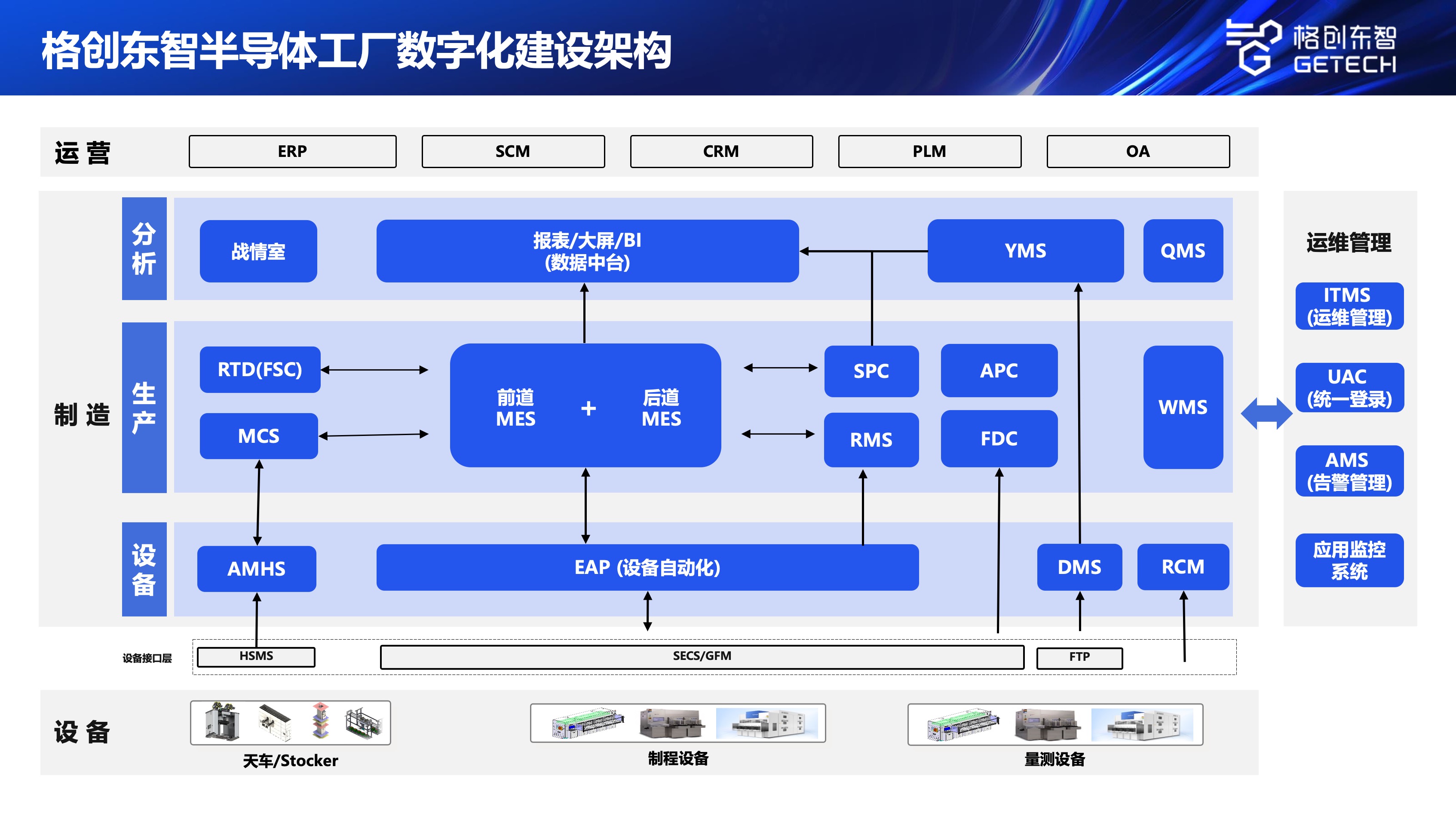

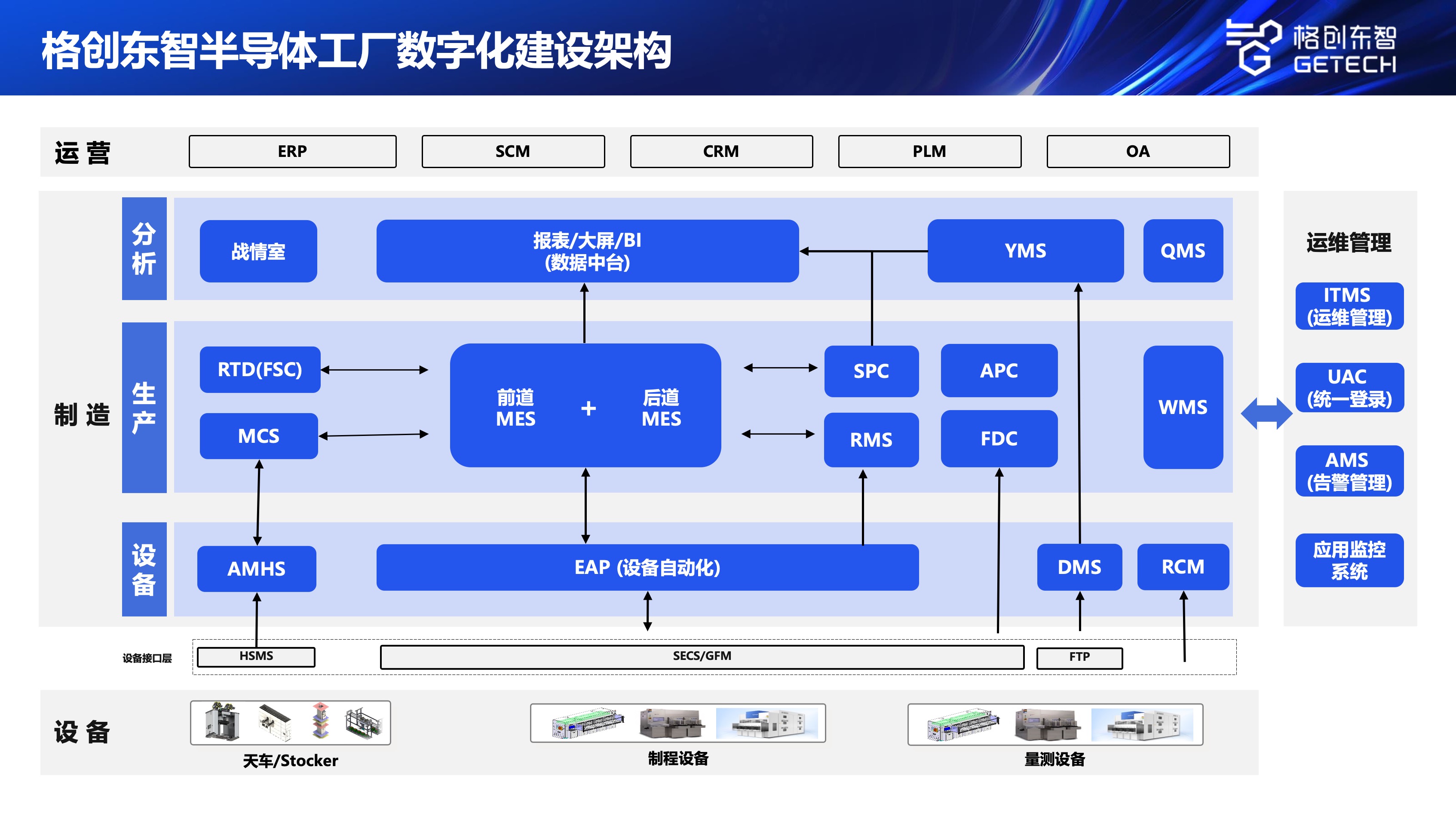

Based on rich practical experience in the pan-semiconductor industry and years of accumulated know-how in customer service, GTRONTEC provides a full-stack software-hardware integrated solution for semiconductor digital factory construction. It covers core scenarios such as production control, quality optimization, logistics handling, and facility management, spanning the entire process from planning and design, systematic facility setup, production information management, to automated logistics upgrades, intelligent application services, and delivery operations. The company has a team of over 400 semiconductor-specific professionals for implementation and delivery, a resource pool of over 500, and a mature operation and maintenance system, offering multi-dimensional self-developed achievements including automation software and hardware, equipment components, renovations, algorithms, and applications.

In the case sharing session, Ma Wei presented GTRONTEC's successful practice in the digital construction of a semiconductor factory. By establishing a production management system centered on MES for the client, it achieved management and traceability of the entire production process; introducing an EAP system enabled dynamic equipment monitoring and real-time alarms, significantly improving automation management; the SPC quality monitoring system implemented engineering data collection, calculation, and statistical analysis, aligning quality and indicators; and the report operation system provided multi-dimensional data display, offering a new digital production management experience. In another case, an automated logistics project for a silicon carbide factory, through the implementation of an AMHS logistics automation solution, the timely delivery rate reached 100%, personnel were reduced by 38%, and capacity increased by 5%. The 'localization' of China's semiconductor industry has entered deep waters. In this round of competition, the main drivers accelerating semiconductor development are artificial intelligence and the energy revolution. In the semiconductor field, GTRONTEC is using the 'AI+CIM+AMHS' software-hardware integrated industrial intelligence solution and end-to-end digital services to collaborate with customers in creating smart factories. The company always upholds the marathon spirit, does difficult but right things, maintains over 80% R&D technology ratio, and is committed to promoting technological progress in the semiconductor industry, providing strong market support for 'deep localization' and sustainable development in the semiconductor field.

The 'localization' of China's semiconductor industry has entered deep waters. In this round of competition, the main drivers accelerating semiconductor development are artificial intelligence and the energy revolution. In the semiconductor field, GTRONTEC is using the 'AI+CIM+AMHS' software-hardware integrated industrial intelligence solution and end-to-end digital services to collaborate with customers in creating smart factories. The company always upholds the marathon spirit, does difficult but right things, maintains over 80% R&D technology ratio, and is committed to promoting technological progress in the semiconductor industry, providing strong market support for 'deep localization' and sustainable development in the semiconductor field.

The 'localization' of China's semiconductor industry has entered deep waters. In this round of competition, the main drivers accelerating semiconductor development are artificial intelligence and the energy revolution. In the semiconductor field, GTRONTEC is using the 'AI+CIM+AMHS' software-hardware integrated industrial intelligence solution and end-to-end digital services to collaborate with customers in creating smart factories. The company always upholds the marathon spirit, does difficult but right things, maintains over 80% R&D technology ratio, and is committed to promoting technological progress in the semiconductor industry, providing strong market support for 'deep localization' and sustainable development in the semiconductor field.

The 'localization' of China's semiconductor industry has entered deep waters. In this round of competition, the main drivers accelerating semiconductor development are artificial intelligence and the energy revolution. In the semiconductor field, GTRONTEC is using the 'AI+CIM+AMHS' software-hardware integrated industrial intelligence solution and end-to-end digital services to collaborate with customers in creating smart factories. The company always upholds the marathon spirit, does difficult but right things, maintains over 80% R&D technology ratio, and is committed to promoting technological progress in the semiconductor industry, providing strong market support for 'deep localization' and sustainable development in the semiconductor field.