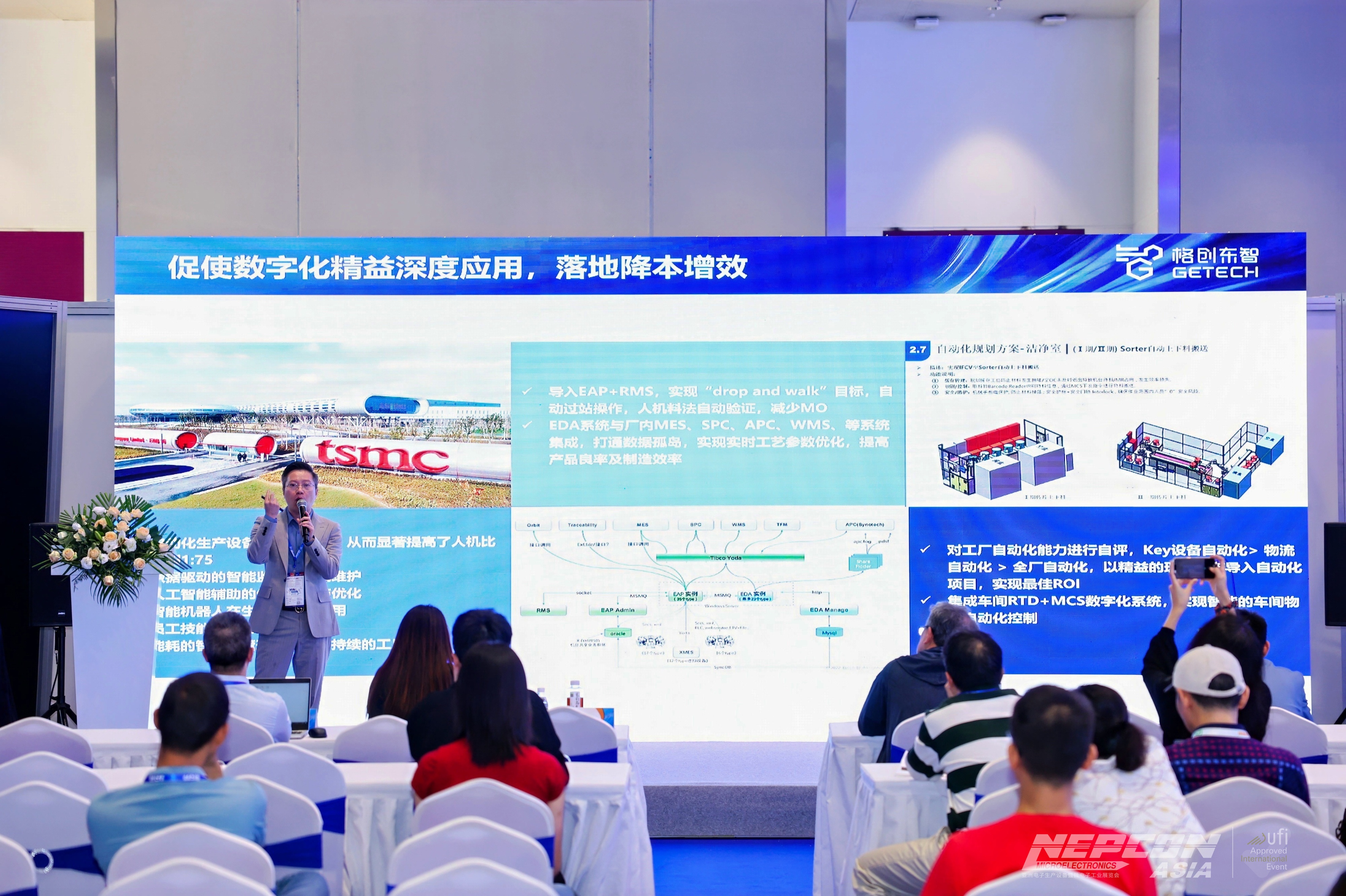

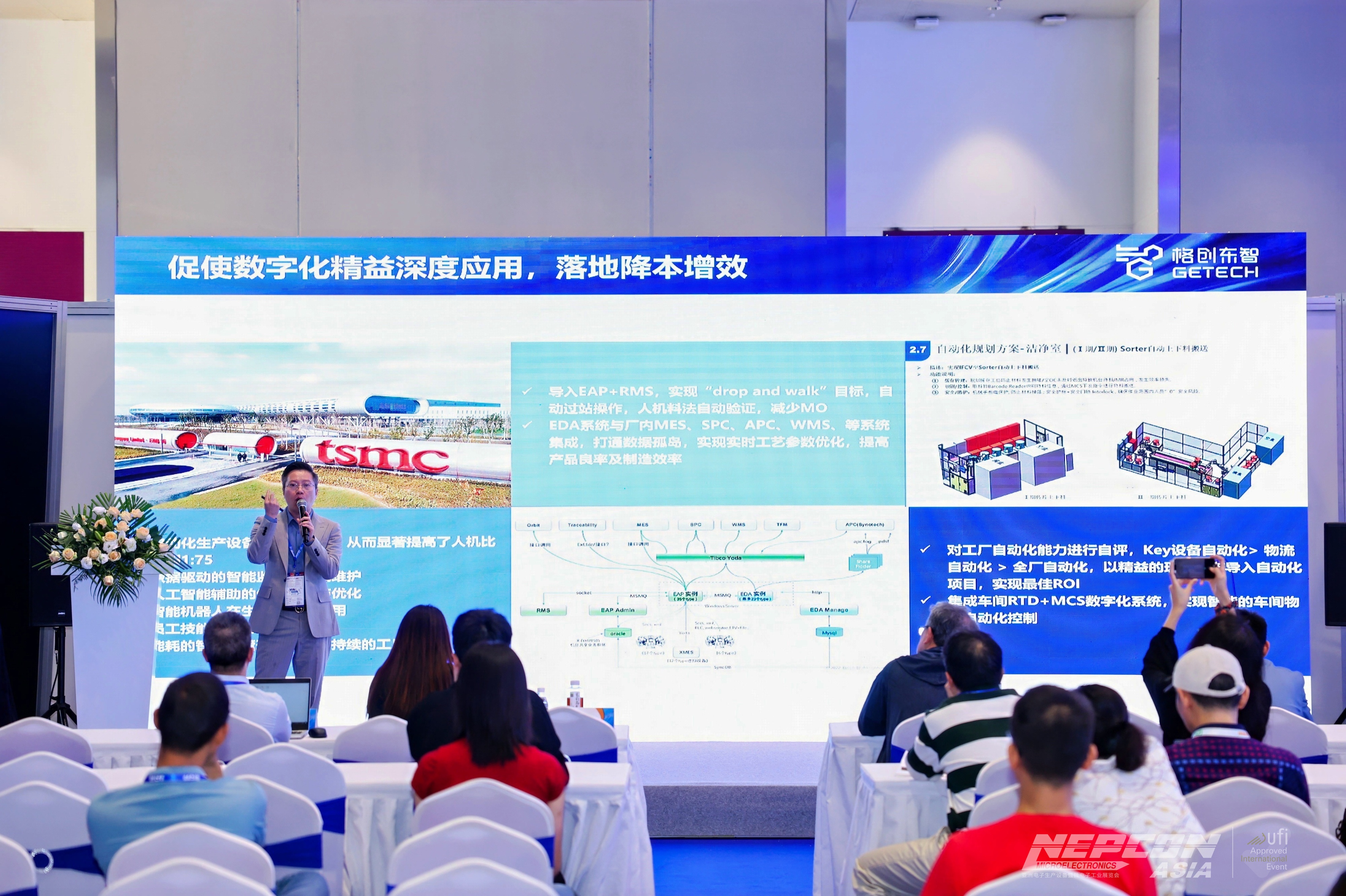

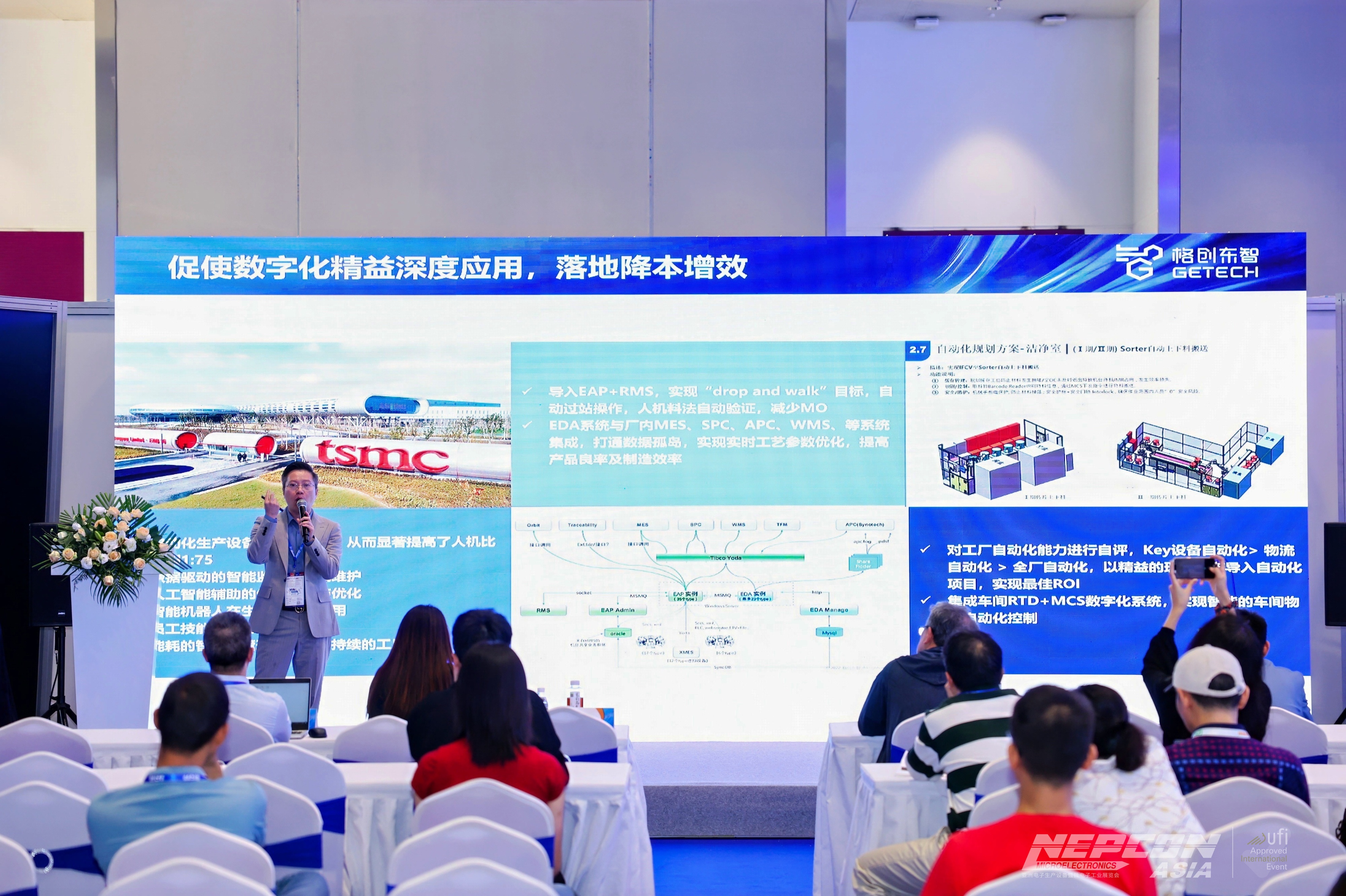

On November 7, Yang Jun, Semiconductor Industry Expert and Head of EAP Business Line at GeChuang Dongzhi, was invited to attend the 2024 7th ICPF Semiconductor Technology and Application Innovation Conference held concurrently with the NEPCON ASIA exhibition. At the SiP and Advanced Semiconductor Packaging and Testing Technology Forum, Yang Jun delivered a keynote speech titled "Exploring Lights-Out Factory in Packaging Manufacturing: A New Strategy to Reshape Human-Machine Efficiency Ratio and Quality Cost", offering profound insights and key pathways for the intelligent transformation of the semiconductor manufacturing industry based on his extensive industry background and practical experience. The forum brought together numerous experts, scholars, and industry elites to discuss process technology experiences and practical application cases, focusing on cutting-edge technologies such as Chiplet and exploring how advanced packaging can achieve higher performance and flexibility. The event provided a multi-faceted analysis of the industry's future development direction and addressed challenges and pain points in semiconductor manufacturing.

Yang Jun proposed three core viewpoints in his speech. First, the bottleneck of intelligent manufacturing lies not in technology but in methodology and talent. Driving the intelligent manufacturing transformation in the semiconductor industry requires more than IT and OT upgrades; business process innovation is the real driving force. Second, he emphasized that the human-machine ratio is not the ultimate goal; companies should pursue value-optimized moderate intelligence. Finally, Yang Jun introduced the "Three Transformations and Four Steps" methodology for building smart factories, which involves deep integration of lean production, informatization, and automation to achieve triple improvements in extreme human efficiency, extreme yield, and extreme cost reduction.

When discussing the key steps to build a smart factory, Yang Jun shared clear insights based on his practical experience: First, leverage SEMI standardization to effectively reduce the cost of data interconnection and equipment automation; Second, restructure business processes by gradually breaking them down from L1 to L7, and solidify and implement them through digital technology to achieve business process informatization; Third, achieve perceptible and self-feedback workshop intelligent control through OT & IT integration; Fourth, transform manufacturing big data and fast data Fast Data into intelligent data, leveraging AI technology to enhance intelligent insights and decision-making. The implementation of these strategies will vigorously promote the development of the semiconductor manufacturing industry towards higher efficiency and intelligence.

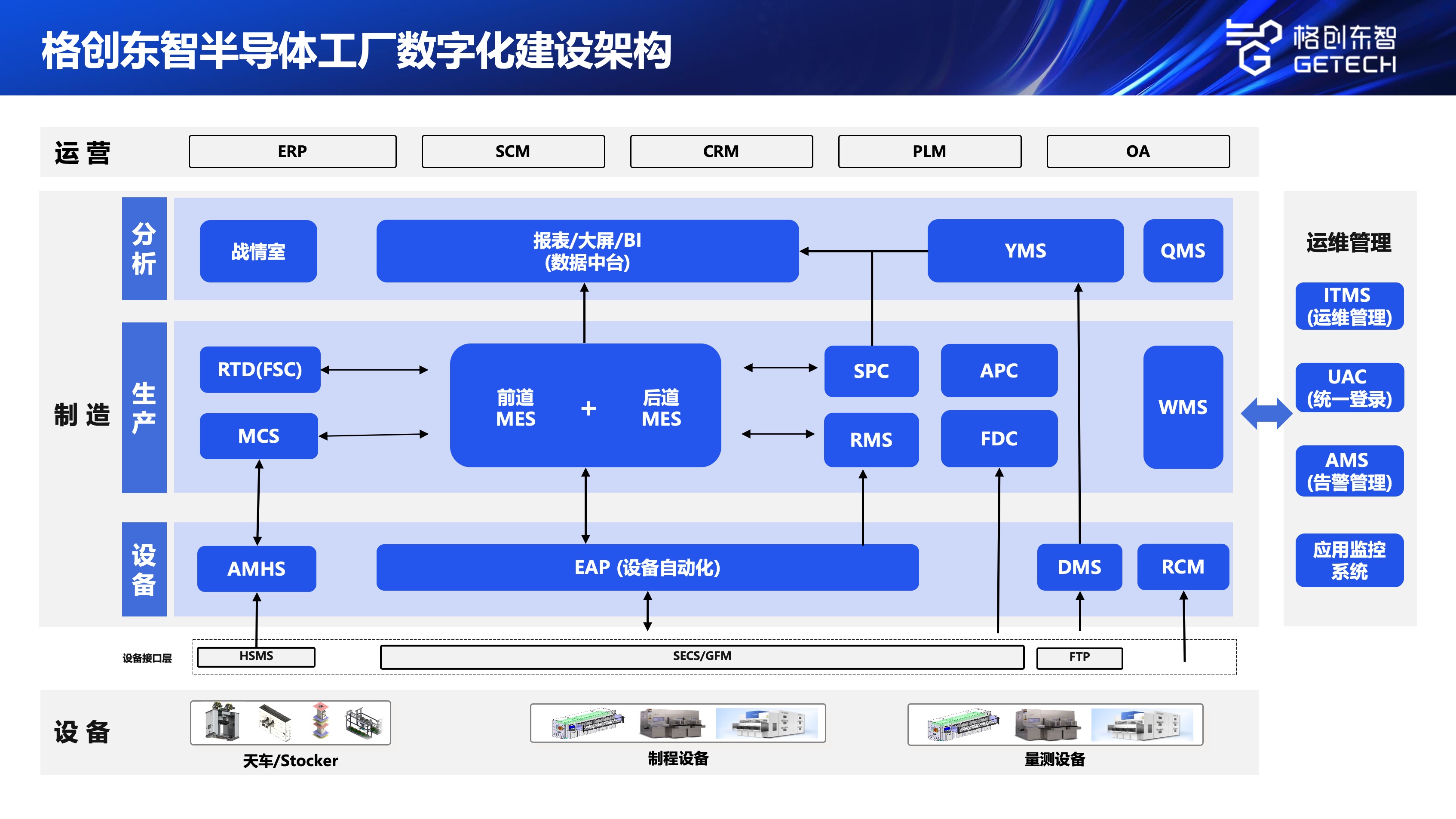

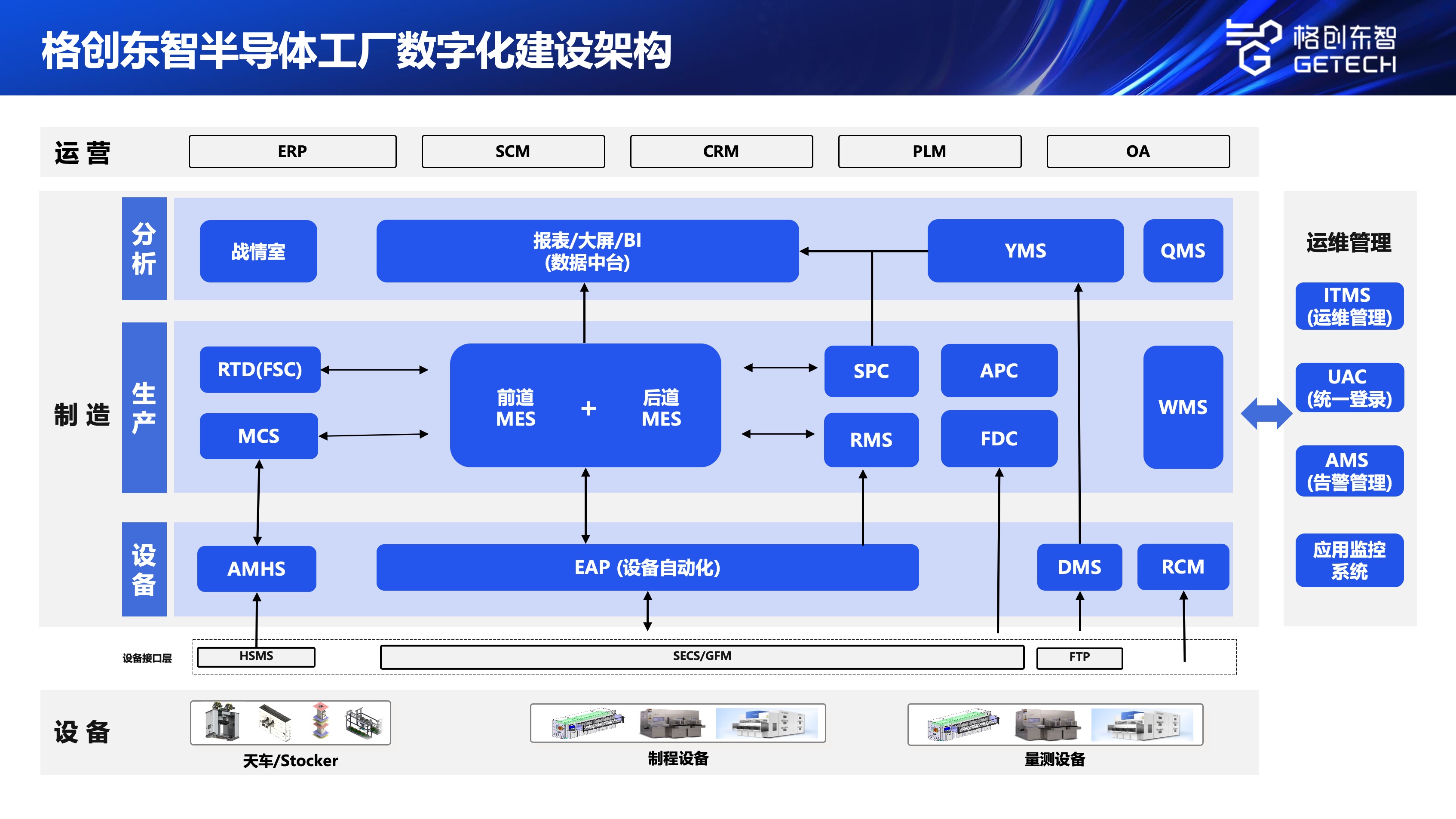

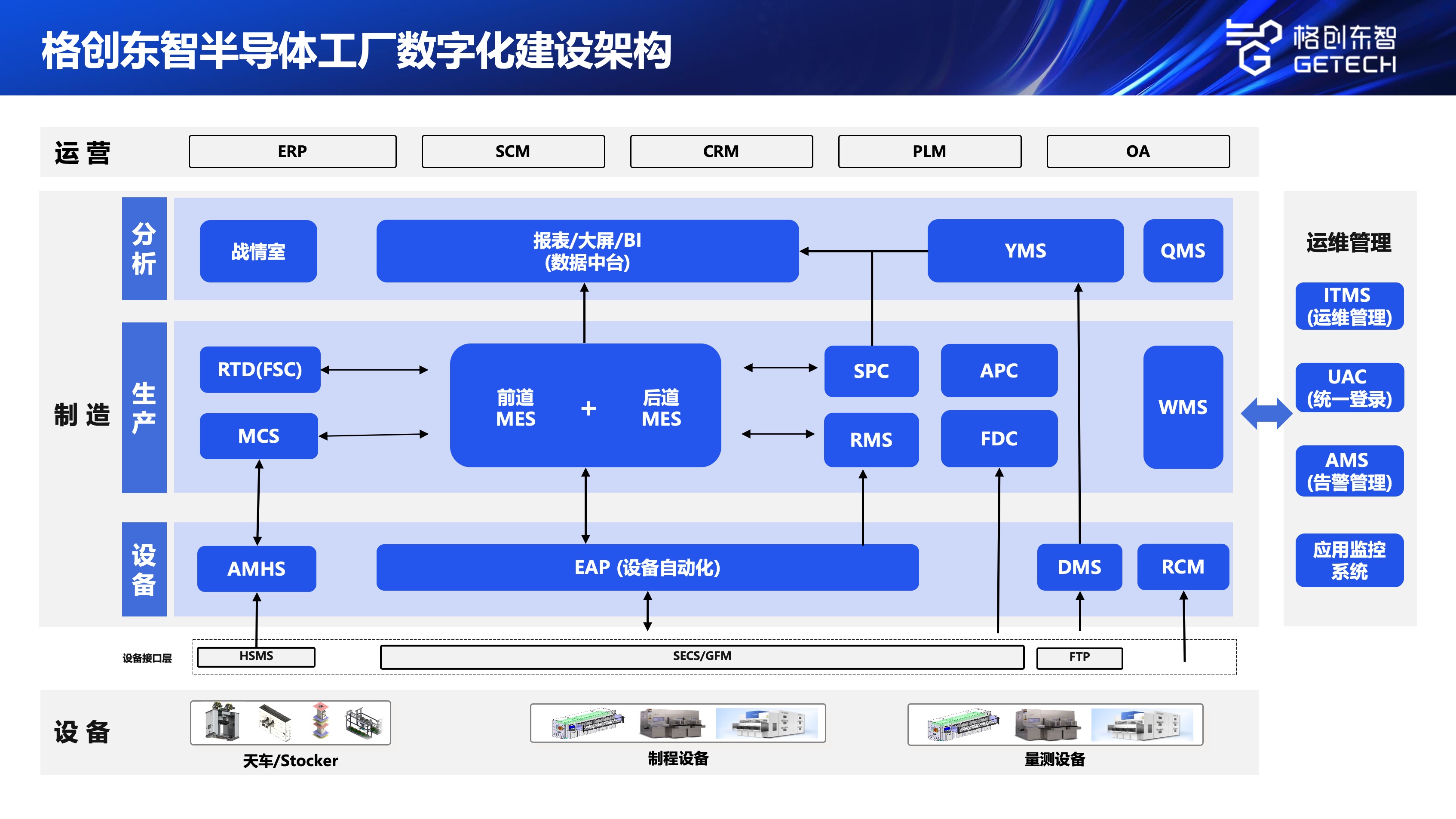

Finally, Yang Jun shared GeChuang Dongzhi's empowerment practices in the intelligent transformation of the semiconductor industry. He introduced how GeChuang Dongzhi uses CIM systems such as EAP, MES, and SPC, along with core intelligent equipment, to achieve automatic data collection, verification, and transmission, thereby reducing manual errors and improving production efficiency. He also demonstrated GeChuang Dongzhi's capabilities in AI modeling, root cause analysis, predictive alarms, and how integrated hardware and software solutions help customers achieve intelligent production.

Finally, Yang Jun shared GeChuang Dongzhi's empowerment practices in the intelligent transformation of the semiconductor industry. He introduced how GeChuang Dongzhi uses CIM systems such as EAP, MES, and SPC, along with core intelligent equipment, to achieve automatic data collection, verification, and transmission, thereby reducing manual errors and improving production efficiency. He also demonstrated GeChuang Dongzhi's capabilities in AI modeling, root cause analysis, predictive alarms, and how integrated hardware and software solutions help customers achieve intelligent production.

As a leading enterprise in the intelligent transformation of semiconductor manufacturing, GeChuang Dongzhi has extensive business布局 and deep technological积累 across the semiconductor packaging and testing industry and the broader semiconductor sector. Its business covers the entire industry chain, from semiconductor materials and wafer manufacturing to packaging and testing. Key products include core CIM systems such as EAP, MES, RMS, QMS, as well as comprehensive smart factory solutions. These product matrices have demonstrated strong service capabilities in multiple implementation cases. For example, GeChuang Dongzhi implemented real-time data collection and modeling analysis of key equipment parameters for an advanced packaging factory, enabling equipment anomaly monitoring and predictive maintenance, significantly improving production efficiency and product yield. These achievements reflect GeChuang Dongzhi's deep service capabilities in the semiconductor industry and its critical role in driving the industry's intelligent transformation.

The semiconductor industry is regarded as the crown of Chinese manufacturing, representing not only the most advanced technology but also undertaking the重任 of domestic substitution in China's advanced manufacturing. As a pioneer in serving the digital transformation of this industry, GeChuang Dongzhi will continue to expand its service space, leveraging absolute advantages in categories such as "AI + Industrial Software + Intelligent Equipment" to lead the semiconductor manufacturing industry towards high-quality development with a professional perspective and firm steps.