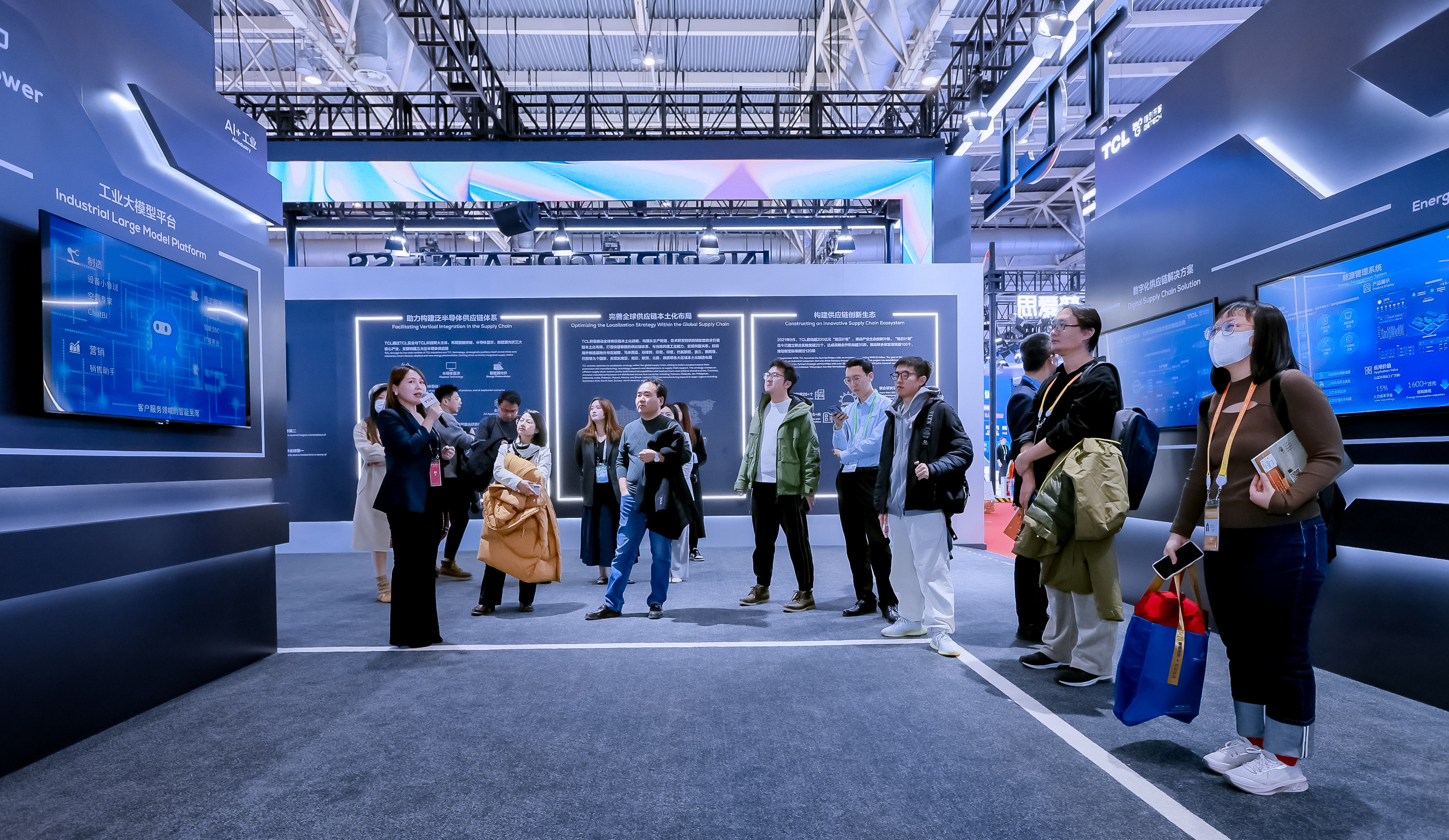

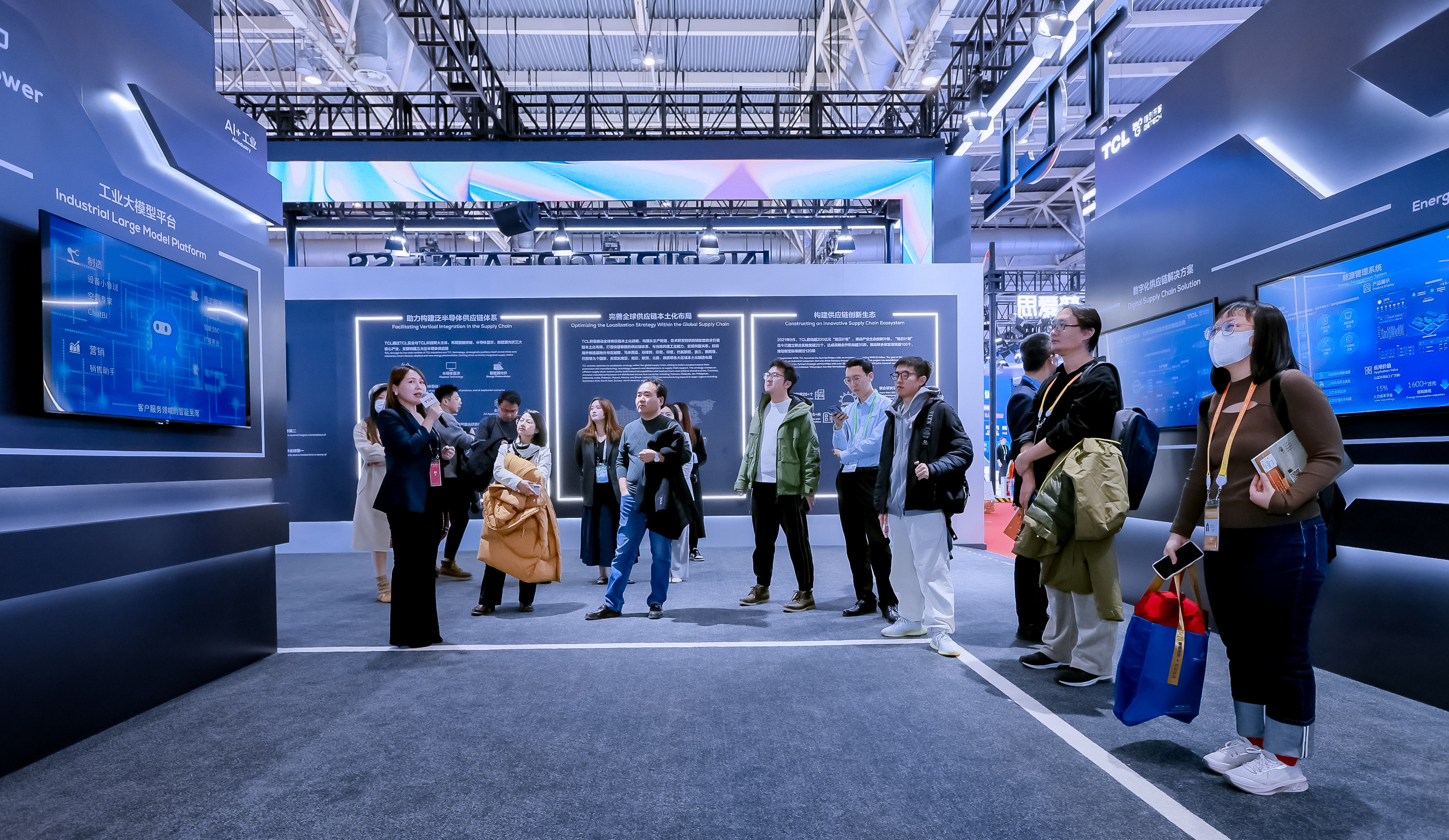

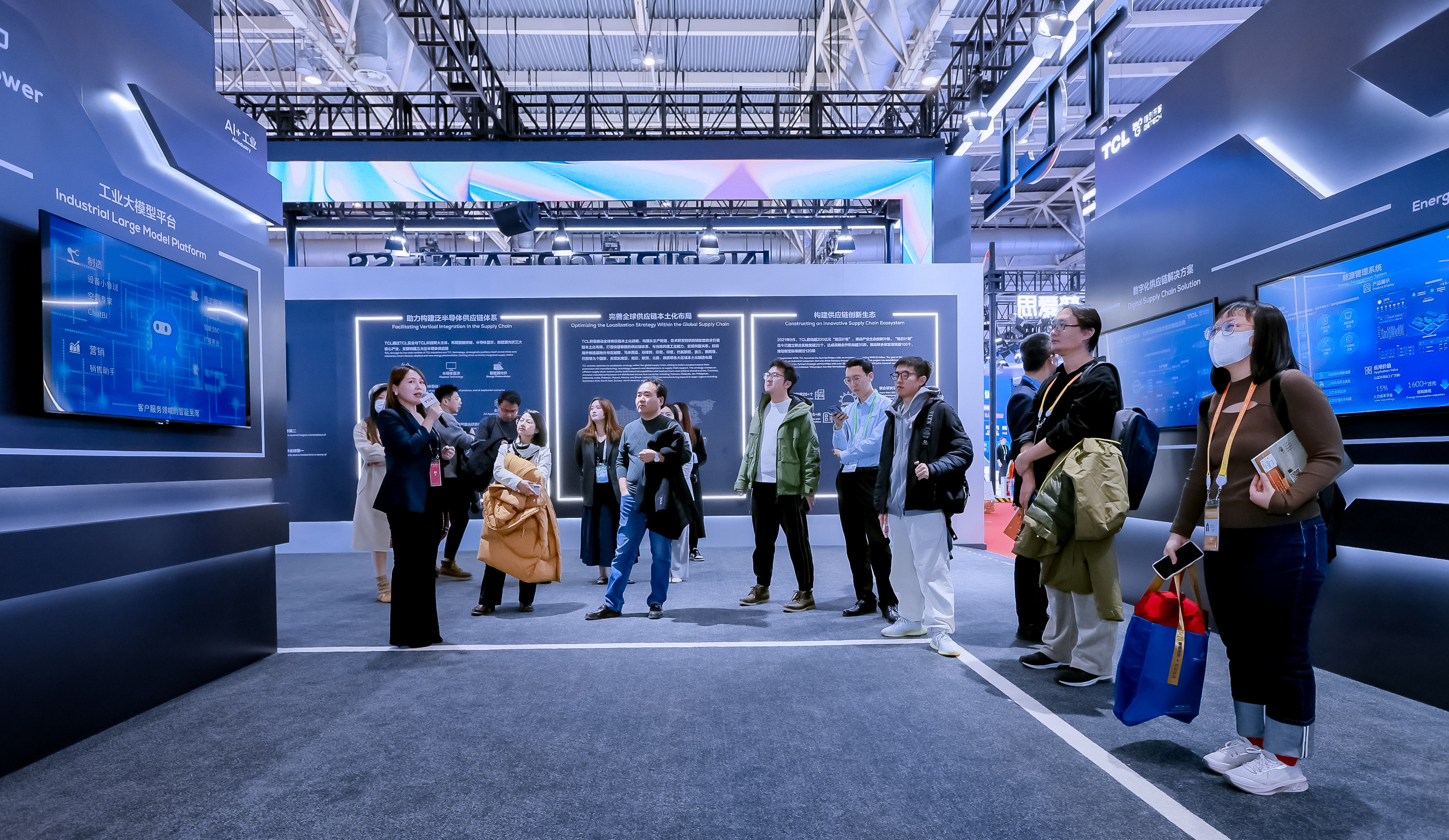

On November 26, the second China International Supply Chain Expo (abbreviated as "Chain Expo") kicked off in Beijing. As the world's first national-level exhibition with "supply chain" as its theme, this conference's theme is "Linking the World, Creating the Future Together". It invited over 600 well-known Chinese and foreign enterprises from more than 50 countries and regions to showcase advanced technologies, products, and supply chain services across various industry chains. TCL Group was invited to appear at the conference, with a 400-square-meter giant special exhibition hall, showcasing its full industry chain product matrix and innovative practices to enhance the resilience and security level of the industry chain and supply chain. Among them, Greatech East Wisdom displayed its cutting-edge capabilities in full AI layout, and its innovatively developed AI business landing practices attracted widespread attention.

TCL Group was invited to appear at the conference, with a 400-square-meter giant special exhibition hall, showcasing its full industry chain product matrix and innovative practices to enhance the resilience and security level of the industry chain and supply chain. Among them, Greatech East Wisdom displayed its cutting-edge capabilities in full AI layout, and its innovatively developed AI business landing practices attracted widespread attention.

Greatech East Wisdom, based on its own practices, set up three exhibition areas around the pan-semiconductor business, using three brushes: AI+ Source Power, AI+ Soft-Hard Digital Intelligence, and AI+ Industry Leadership, vividly depicting a new picture from AI R&D driving, AI platform value addition, to AI scene landing and AI industry empowerment, displaying platform products such as industrial AI platform, industrial large model platform, scene solutions like digital supply chain, energy and carbon management, AOI intelligent visual inspection, quality management, and innovative applications for enterprises and industries such as TCL CSOT, semiconductor, new energy, etc. Among them, the energy and carbon management solution helped the company successfully be listed as a technology provider by the United Nations WIPO GREEN, and the QMS application in the quality management solution won first place in the semiconductor industry on the list of China's largest enterprise-level software selection and procurement platform "SoftServe Home".

Greatech East Wisdom, based on its own practices, set up three exhibition areas around the pan-semiconductor business, using three brushes: AI+ Source Power, AI+ Soft-Hard Digital Intelligence, and AI+ Industry Leadership, vividly depicting a new picture from AI R&D driving, AI platform value addition, to AI scene landing and AI industry empowerment, displaying platform products such as industrial AI platform, industrial large model platform, scene solutions like digital supply chain, energy and carbon management, AOI intelligent visual inspection, quality management, and innovative applications for enterprises and industries such as TCL CSOT, semiconductor, new energy, etc. Among them, the energy and carbon management solution helped the company successfully be listed as a technology provider by the United Nations WIPO GREEN, and the QMS application in the quality management solution won first place in the semiconductor industry on the list of China's largest enterprise-level software selection and procurement platform "SoftServe Home".

Industrial AI is the "AI engine" grown by Greatech East Wisdom based on years of field-verified industrial software and intelligent equipment hardware and software, accumulation of industry Know-How, externally promoting benchmark customers in building digital intelligence capabilities in manufacturing execution, equipment automation, quality management, energy and carbon management, logistics automation, digital supply chain, etc., to better face the opportunities and challenges brought by market demand iteration. Every step forward integrates core elements such as technology, talent, ecology, and the stringent pursuit of extreme human efficiency, extreme yield rate, and extreme cost in serving the pan-semiconductor industry.

In the AI+ Source Power exhibition area, Greatech East Wisdom's self-developed East Wisdom Industrial Application Intelligent Platform (abbreviated as "East Wisdom Platform") has been selected for three consecutive years as a cross-industry cross-domain industrial internet platform by the Ministry of Industry and Information Technology. The East Wisdom Platform solidifies the core capabilities of "device connection + data modeling + application empowerment", with the industrial AI platform and industrial large model platform as the core, building the core operating system for smart factories in the pan-semiconductor industry, and combining self-developed upper-layer applications and solutions, has cumulatively connected over 1 million devices, providing industrial intelligent solutions to over 30,000 enterprises, empowering enterprise digital transformation.

In the AI+ Source Power exhibition area, Greatech East Wisdom's self-developed East Wisdom Industrial Application Intelligent Platform (abbreviated as "East Wisdom Platform") has been selected for three consecutive years as a cross-industry cross-domain industrial internet platform by the Ministry of Industry and Information Technology. The East Wisdom Platform solidifies the core capabilities of "device connection + data modeling + application empowerment", with the industrial AI platform and industrial large model platform as the core, building the core operating system for smart factories in the pan-semiconductor industry, and combining self-developed upper-layer applications and solutions, has cumulatively connected over 1 million devices, providing industrial intelligent solutions to over 30,000 enterprises, empowering enterprise digital transformation.

In the AI+ Soft-Hard Digital Intelligence exhibition area, based on the Chain Expo background, Greatech East Wisdom publicly released a digital supply chain solution for the pan-semiconductor industry. This solution starts with advanced supply chain production planning, using self-developed optimization algorithms to solve complex production scheduling optimization in semiconductor factories, improving factory production efficiency. At the same time, it is gradually expanding to supply chain collaboration between upstream and downstream suppliers and customers, enhancing the efficiency of the entire supply chain, and through the supply chain control tower, achieving visibility, controllability, and decision support across the entire supply chain. Undeniably, Greatech East Wisdom has always been committed to the localization replacement of industrial applications. Through years of accumulated supply chain management business experience and algorithm talent, the company is accelerating the launch and replacement of self-developed industrial software products with various industries of TCL Group, mastering core soft capabilities in their own hands, and by building standardized system products, shifting from previously one factory one set of custom-developed systems to meeting customization needs through self-defined configuration based on standardized products. It is precisely due to rich semiconductor manufacturing operation experience and foundation, continuously iterating optimization algorithms, and continuous polishing and evolution in TCL Group's pan-semiconductor manufacturing business that Greatech East Wisdom's solutions have the reliability for landing and the confidence for replication and promotion across the industry chain.

In the AI+ Soft-Hard Digital Intelligence exhibition area, based on the Chain Expo background, Greatech East Wisdom publicly released a digital supply chain solution for the pan-semiconductor industry. This solution starts with advanced supply chain production planning, using self-developed optimization algorithms to solve complex production scheduling optimization in semiconductor factories, improving factory production efficiency. At the same time, it is gradually expanding to supply chain collaboration between upstream and downstream suppliers and customers, enhancing the efficiency of the entire supply chain, and through the supply chain control tower, achieving visibility, controllability, and decision support across the entire supply chain. Undeniably, Greatech East Wisdom has always been committed to the localization replacement of industrial applications. Through years of accumulated supply chain management business experience and algorithm talent, the company is accelerating the launch and replacement of self-developed industrial software products with various industries of TCL Group, mastering core soft capabilities in their own hands, and by building standardized system products, shifting from previously one factory one set of custom-developed systems to meeting customization needs through self-defined configuration based on standardized products. It is precisely due to rich semiconductor manufacturing operation experience and foundation, continuously iterating optimization algorithms, and continuous polishing and evolution in TCL Group's pan-semiconductor manufacturing business that Greatech East Wisdom's solutions have the reliability for landing and the confidence for replication and promotion across the industry chain.

Similarly, besides the digital supply chain, various scene solutions developed by Greatech East Wisdom with the core concept of "AI in Everywhere" have been implemented and achieved significant results in key enterprises and industries such as TCL CSOT, semiconductor, new energy, helping many customers build an "AI engine", improving production and operation management efficiency from the perspective of front-line engineers, moving towards high-quality development.

Similarly, besides the digital supply chain, various scene solutions developed by Greatech East Wisdom with the core concept of "AI in Everywhere" have been implemented and achieved significant results in key enterprises and industries such as TCL CSOT, semiconductor, new energy, helping many customers build an "AI engine", improving production and operation management efficiency from the perspective of front-line engineers, moving towards high-quality development.

For example, for TCL CSOT display industry chain main scenarios, Greatech East Wisdom's self-developed "AI engine" has typical applications in scenes such as ADC, computer vision enhanced quality applications, expert large model assistant. Among them, the ADC application provided by Greatech East Wisdom, through AI deep learning algorithms, from three major modules: training platform, inference platform, and resource scheduling platform, achieves algorithm model self-learning, self-modeling, automatically detecting, classifying, and automatically handling defects in the production process, locking abnormal concentration and causes. After the application was deployed and launched at TCL CSOT, through continuous technological iteration, it formed TCL's independent technical capability, accuracy increased from 85% to 95%, saving manpower by 12 times, detection efficiency per card goods improved by more than 5 times, saving over 50 million yuan annually, and received an exclusive interview from CCTV's "Made in China with Intelligence" program. Additionally, Greatech East Wisdom is joining hands with TCL Industrial Research Institute and TCL CSOT to build a large model for the semiconductor display industry, and AI applications in the future display field may usher in an explosive period.

The industry chain and supply chain connect the economies of various countries, linking the capital flow, industry flow, and technology flow of global enterprises. Building a stable, safe, and smooth global industry chain and supply chain system is the common expectation of the international business community and the common responsibility of the international society.

The industry chain and supply chain connect the economies of various countries, linking the capital flow, industry flow, and technology flow of global enterprises. Building a stable, safe, and smooth global industry chain and supply chain system is the common expectation of the international business community and the common responsibility of the international society.

As a pioneer enterprise in the deep integration of AI and industry, Greatech East Wisdom relies on the three pillars of the "AI+ Industrial Software+ Intelligent Equipment" strategy, carrying out AI empowerment around scenarios such as manufacturing production, equipment, quality, energy and carbon, logistics, supply chain, etc., innovatively exploring new ways for artificial intelligence to empower new industrialization, helping to build a modern industrial system for industrial AI.

In the future, Greatech East Wisdom will continue to focus on new scenes and new demands of industrial AI in various industry fields, providing cutting-edge scene applications and solution capabilities to accelerate the collaborative development of the industry chain and supply chain, accelerate new industrialization, and help build a digital economy system and high-quality development of manufacturing.