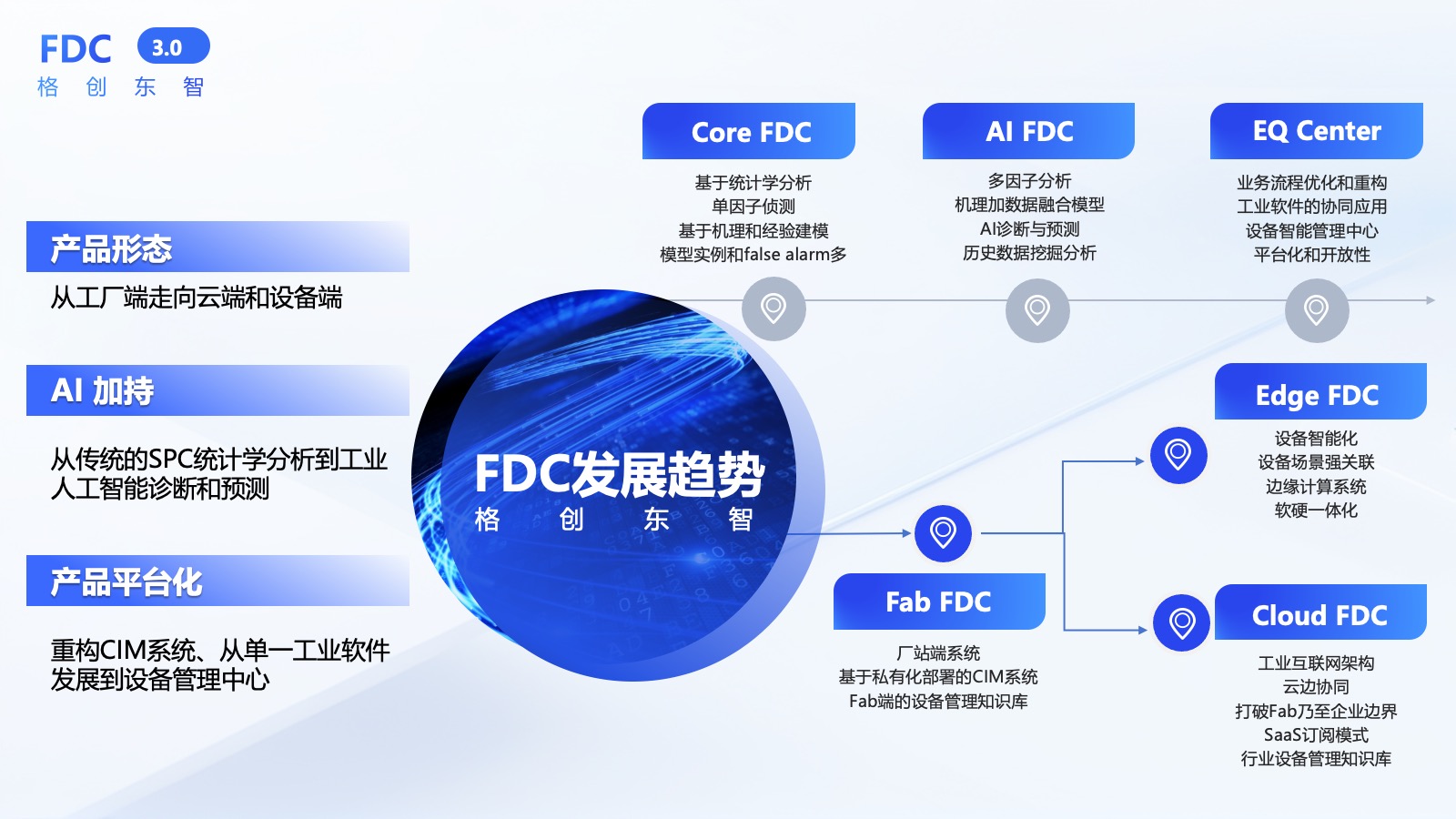

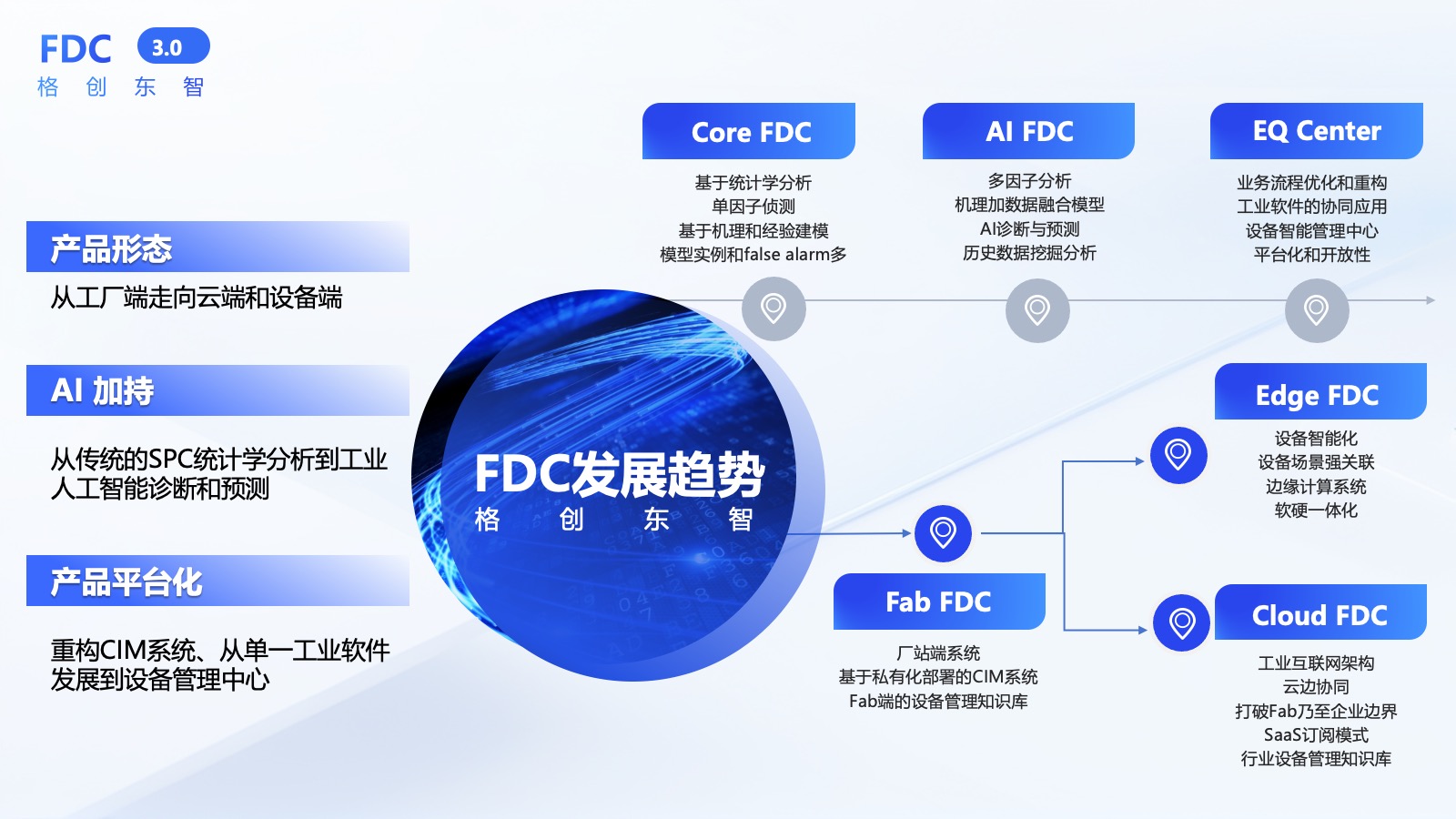

Recently, GTRONTEC independently developed the third-generation FDC product—G-FDC Equipment Fault Detection and Classification System (referred to as "G-FDC")—officially launched. Leveraging deep semiconductor industry know-how and "AI + industrial software" R&D capabilities, GTRONTEC G-FDC introduces a Logic Rule Engine, breaking down equipment module barriers, rule barriers, and OCAP barriers, making the FDC system more flexible and convenient. Future integration of more AI technologies will enable AI-powered FDC, achieving intelligent fault diagnosis and classification to maximize equipment efficiency, thereby helping semiconductor fabs improve production efficiency and yield while reducing costs.

G-FDC 3.0 leads the industry with enhanced functionality and superior performance,

supporting enterprise-level unified management

As known, semiconductor equipment involves huge investment costs, with over 75% of fab construction costs spent on equipment procurement. Meanwhile, these semiconductor equipment generate billions of data points daily.Thus, how to collect equipment data, detect faults, analyze and predict anomalies, and maximize equipment efficiency through FDC is one of the primary methods for semiconductor fabs to reduce costs and improve efficiency.

After multiple R&D iterations, the newly released G-FDC 3.0 by GTRONTEC offers the following advantages:- Added equipment OEE analysis module, Tool Match equipment variance analysis module, optimized MVA module, etc., making the product more comprehensive;

- Adopts superior technology combinations to ensure real-time and reliable processing of big data collection, computation, and storage; complete secondary development and O&M support solutions, supporting rule engines for flexibility and scalability;

- Uses big data architecture, improving processing performance by 10x compared to traditional FDC; distributed cluster deployment with 99.999% availability; high performance, high throughput, HA high availability; no limit on parameters and equipment count, resources elastically scalable;

- Beyond traditional fab-deployed FDC, G-FDC offers an enterprise version supporting centralized management via a distributed architecture, enabling cross-fab (Cross Fab) FDC parameter applications based on a big data platform, including equipment variance analysis (Tool Matching), specification optimization (Spec Tighten), data/specification/alarm comparison, etc., achieving group-wide, standardized, and unified FDC management.

Taking a 12-inch Wafer Fab with extreme data volume as an example:2000 equipment/15,000 chambers, 50 million model instances/2 million real-time parallel summary model instances, 800,000 SENSOR parameters…

Let’s review G-FDC 3.0 performance evaluation data:- Overall data link latencyG-FDC 3.0 controls data link latency within 500ms for ~85% of cases, within 1s for 97%; 3-5x faster than traditional FDC;

- 30+ days summary parameter report query and graphingG-FDC 3.0 takes only 1 minute, 8-15x faster than traditional FDC;

- Real-time anomaly detectionUnder tens of millions of detection model instances, G-FDC 3.0 completes OCAP detection and alerts in about 1-2 seconds.

Deepening AI FDC deployment for intelligent fault diagnosis and classification

Traditional FDC systems have existed for years, but due to rule-based static models, they cannot adapt to process changes, often leading to model failures. Inaccurate modeling and model failures result in high false alarm rates, sometimes exceeding 30%. Additionally, traditional FDC lacks intelligent fault diagnosis and classification capabilities, leading to low quality and inefficiency.As an AI-driven industrial intelligence solutions provider, GTRONTEC is committed to integrating advanced AI technologies into industrial software. AI FDC is one such initiative.

AI FDC introduces AI technologies, combining machine learning and deep learning, utilizing real-time equipment process and measurement data for automated modeling. AI FDC features self-awareness and self-adaptive capabilities, dynamically perceiving and adapting to environmental and process changes, thereby enhancing model performance and accuracy.

For example, in dry etching scenarios, process engineers previously relied on manual experience to build FDC virtual models for anomaly wafer interception via arc monitoring, which was inefficient and still led to productivity impacts or even batch scratches and damage. After implementing GTRONTEC’s AI FDC, multi-factor systematic analysis identified key influencing factors such as temperature and conductivity. By analyzing related factors across sites, better anomaly wafer interception efficiency was achieved.

For example, in dry etching scenarios, process engineers previously relied on manual experience to build FDC virtual models for anomaly wafer interception via arc monitoring, which was inefficient and still led to productivity impacts or even batch scratches and damage. After implementing GTRONTEC’s AI FDC, multi-factor systematic analysis identified key influencing factors such as temperature and conductivity. By analyzing related factors across sites, better anomaly wafer interception efficiency was achieved.

Most domestic deployment projects, G-FDC highly praised by customers

GTRONTEC has the largest and most professional FDC product team in China, with 30+ R&D and project delivery personnel. Core members come from leading FABs and industrial software companies, possessing complete FDC solutions and implementation capabilities, professional talent reserves, and delivery experience.

Through continuous efforts, GTRONTEC has gradually broken the monopoly of foreign FDC vendors. Successful cases exist in mainstream 8-inch and 12-inch fabs, as well as advanced packaging plants. Full functional localization replacement for multiple foreign FDC systems has been achieved, ensuring seamless data migration and smooth transition during system switches.

Currently, GTRONTEC FDC has been deployed in 10+ fabs, covering 200+ equipment types and 5000+ devices, making it the provider with the most semiconductor industry deployment cases in China.

Step by step, long journeys are covered. It is through each product iteration and optimization that GTRONTEC FDC projects have accumulated strength and gained repeated customer recognition. In the future, GTRONTEC will integrate edge computing and AI technologies,聚合 with existing FDC/SPC/APC/AMS/EAP products to form an equipment-centric intelligence solution, achieving higher OEE, better CPK, smarter equipment, and wiser industry.

Step by step, long journeys are covered. It is through each product iteration and optimization that GTRONTEC FDC projects have accumulated strength and gained repeated customer recognition. In the future, GTRONTEC will integrate edge computing and AI technologies,聚合 with existing FDC/SPC/APC/AMS/EAP products to form an equipment-centric intelligence solution, achieving higher OEE, better CPK, smarter equipment, and wiser industry.