AI·Seeing the Future, Tracing the Growth Path of GTRONTEC in Industrial AI from TCL Global Technology Innovation Conference -- Replication

On December 11, the TCL Global Technology Innovation Conference (TIC2024) was held as scheduled in Shenzhen. The conference, themed "AI·Seeing the Future," focused on AI applications, smart terminals, semiconductor displays, new energy photovoltaics, and other fields. Since its inception in 2004, this marks the 11th edition of the event. The conference brought together numerous academicians, top experts, and hundreds of industry leaders and upstream and downstream partners to discuss new drivers for high-quality industrial development.

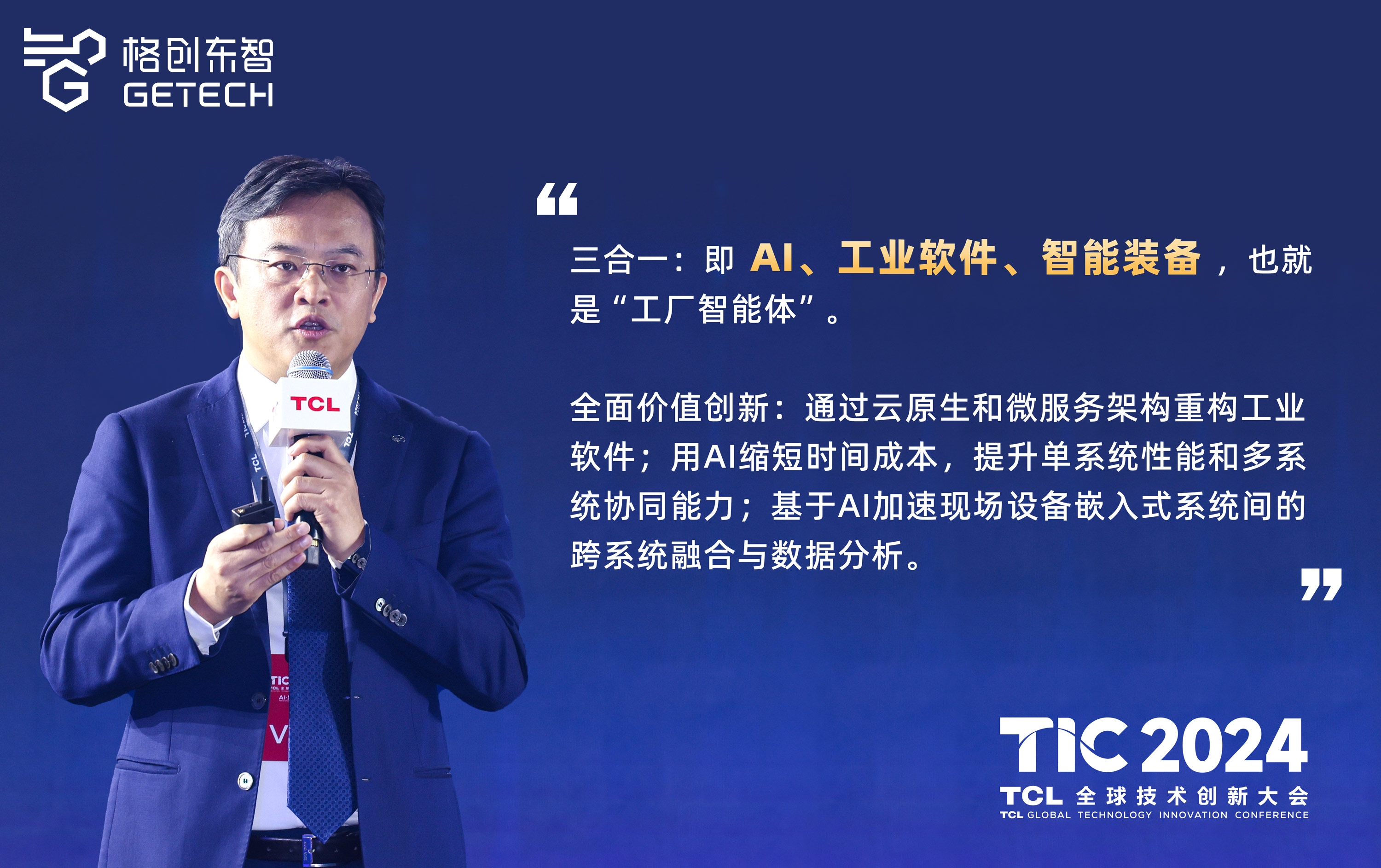

At the conference, He Jun further shared cases of GTRONTEC empowering factory intelligence: technology-driven AI-FDC achieving upgrades from static to dynamic models, ecosystem-co-built CIM Smart Foundation enabling multi-system intelligent collaboration, and the platform-based development of core AI capabilities. When discussing the platformization of AI capabilities, He Jun emphasized that by integrating functions such as application orchestration Studio, knowledge base Index, model service Service, enterprise/industry Plugin, and smart report Engine into its self-developed software and hardware, GTRONTEC maximizes performance to meet clients' demands for extreme efficiency, yield, and cost-effectiveness.

Later, during the TCL Technology Innovation Awards ceremony, GTRONTEC’s solutions in defect detection and AMHS won four awards. Among them, the AI Defect Detection and Automatic Repair System, developed in collaboration with TCL Industrial Research Institute and TCL CSOT, once again received the TCL Technology Innovation Gold Award.

Recognizing the long-term value of AI in enhancing factory resilience and intelligence, He Jun participated in a group interview with dozens of media outlets, including The Paper and China Business Journal, further explaining the key factors in integrating AI technology with manufacturing.

When discussing GTRONTEC’s industrial AI business layout, He Jun noted that GTRONTEC has implemented AI across various end-to-end scenarios, including R&D, production, equipment, and sales, though the depth varies depending on the openness of data from different endpoints. Regarding the key factors for integrating AI technology with manufacturing, He Jun emphasized the importance of correctly understanding and defining AI, possessing the foundational ability to harness AI, and conducting top-down systematic architectural design. On the topic of differentiated advantages in the industrial AI field, He Jun expressed confidence in comprehensive enterprises with industrial backgrounds, self-developed software capabilities, equipment understanding, and AI algorithm expertise. He believes that GTRONTEC, nourished by its TCL roots, has developed both internal and external strengths, giving it a competitive edge. When discussing how industrial software service providers should expand into foreign markets, He shared GTRONTEC’s approach: first, focus on the industry, deeply cultivating the pan-semiconductor sector, and adhere to a strategy of prioritizing heavy then light investments—deploying solutions first before standardizing operations to achieve sustainable revenue in the future. Additionally, in-depth exchanges were held on issues such as energy-carbon optimization and the slow adoption of AI in manufacturing.

Starting from TCL, GTRONTEC is demonstrating world-class industrial AI practices through its technological pioneering efforts. Through continuous innovation and deep industry collaboration, GTRONTEC not only drives the intelligent transformation of the TCL Group but also contributes to the digital transformation and sustainable development of global manufacturing.