Xinde Semiconductor QMS Project Officially Launched, GTRONTEC Accelerates Advanced Intelligent Manufacturing Quality Revolution

2025-02-19

Recently, GTRONTEC completed the demand research for the Xinde Semiconductor QMS project and officially launched project delivery. Through nearly a month of demand investigation, GTRONTEC customized a product full-lifecycle QMS system based on the customer's urgent need to solve main bottlenecks such as the original QMS system being complex to use, weak functional extensibility, and low compliance with actual business, improving the customer's QMS system status according to local conditions. After the project launch, GTRONTEC will combine advanced quality management models and systems from peers in the same industry to promote delivery, provide the most agile system user experience for customers, and carry out a series of quality management optimization services, boosting customer's high-quality development.

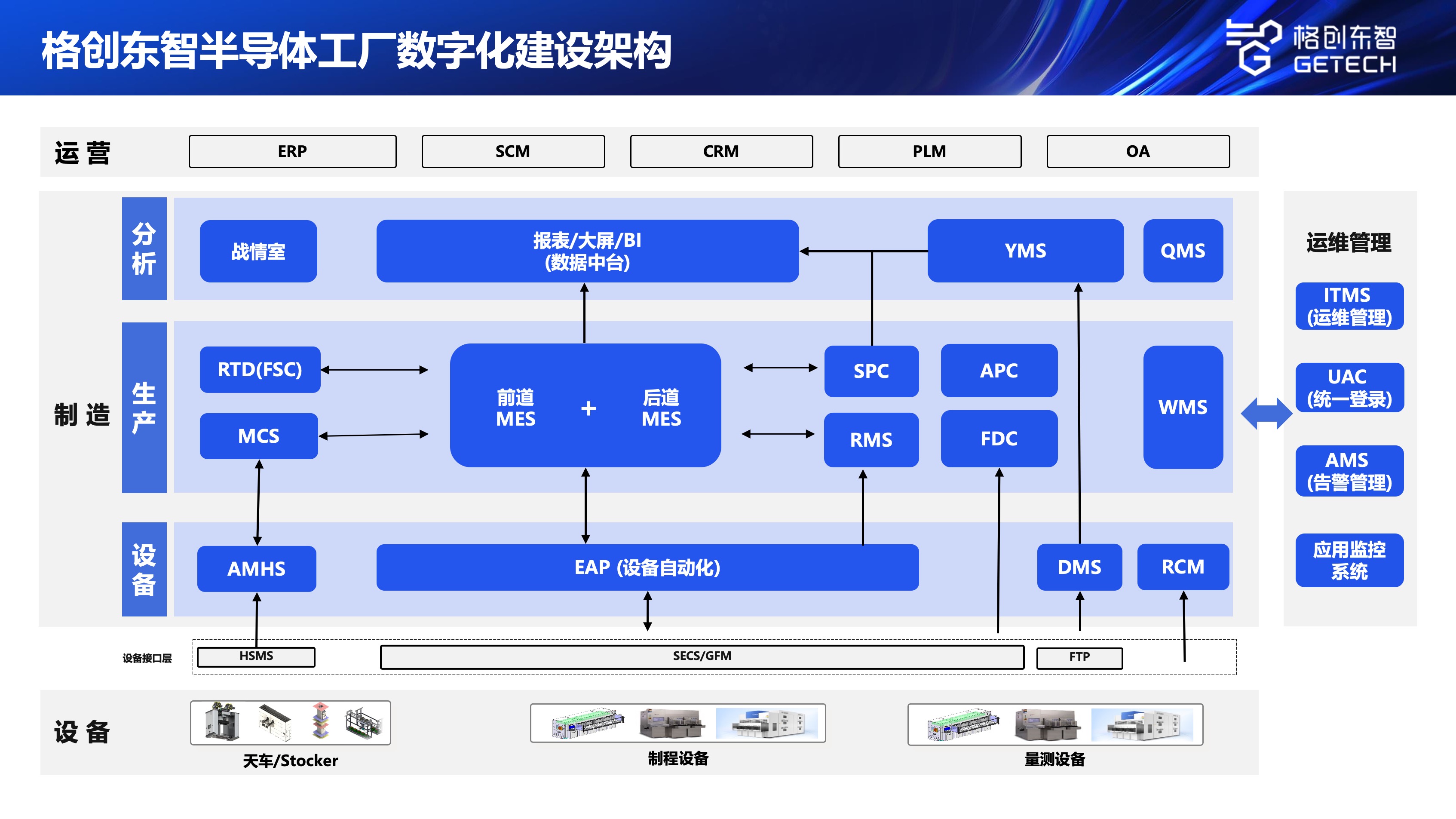

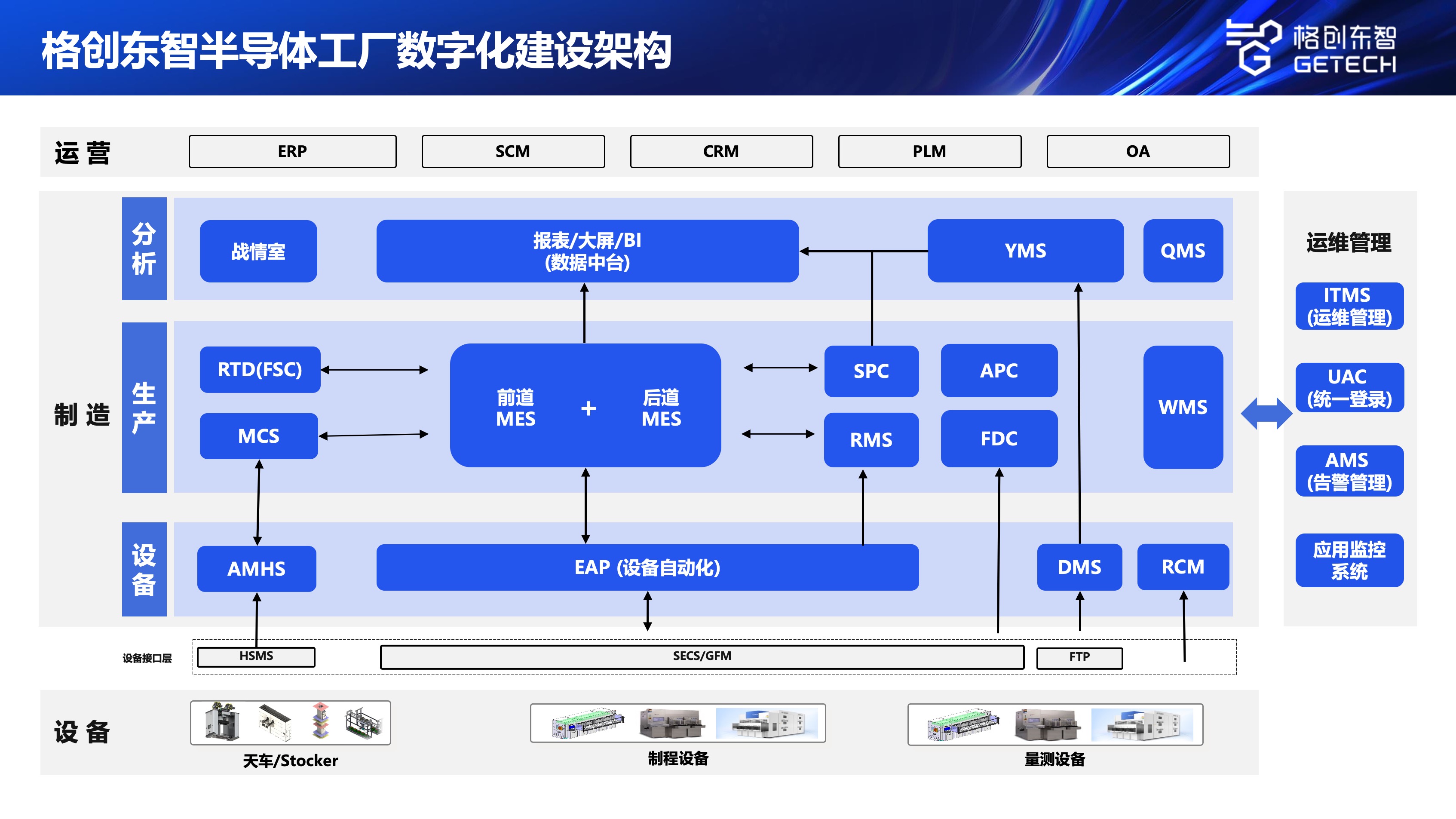

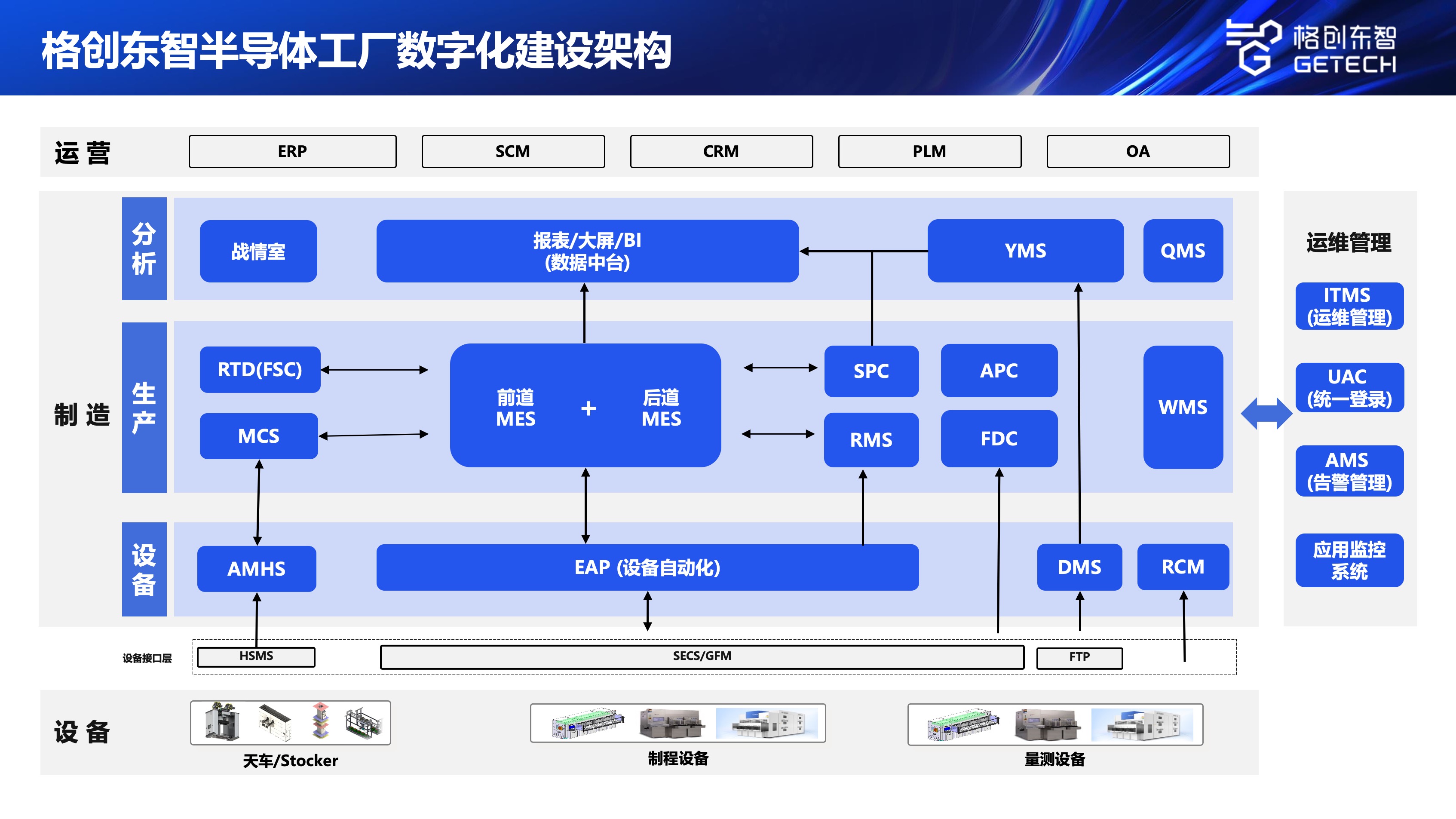

Xinde Semiconductor is a high-tech enterprise focusing on mid-to-high-end semiconductor integrated circuit packaging and testing business, mainly engaged in high-end packaging and testing technologies such as bumping, WB packaging, flip-chip packaging, system-in-package (SiP), heterogeneous packaging (2.5D/3D Chiplet), and testing (including CP and FT) one-stop services. With deep technical accumulation in the advanced packaging field and one-stop high-end packaging and testing service capabilities, it has occupied an important position in the domestic packaging and testing market and is expected to become a world-class packaging and testing enterprise. GTRONTEC's self-controllable QMS quality management solution covers incoming inspection management, process quality management, supplier quality management, after-sales quality management, quality system management, statistical analysis management, and more. Through digital quality management, it establishes a quality information management system that runs through the entire lifecycle from user needs, design, process, production manufacturing, quality inspection, to operation maintenance, building a quality information management platform based on data standardization and flowchart standardization for quality management, improving the utilization rate of quality data, enhancing the level of networking and informatization, and strengthening the core competitiveness of the enterprise.

GTRONTEC's self-controllable QMS quality management solution covers incoming inspection management, process quality management, supplier quality management, after-sales quality management, quality system management, statistical analysis management, and more. Through digital quality management, it establishes a quality information management system that runs through the entire lifecycle from user needs, design, process, production manufacturing, quality inspection, to operation maintenance, building a quality information management platform based on data standardization and flowchart standardization for quality management, improving the utilization rate of quality data, enhancing the level of networking and informatization, and strengthening the core competitiveness of the enterprise. Customers choose to partner with GTRONTEC as the service leader, besides valuing the adaptability and advancement of GTRONTEC's QMS solution, more importantly, value GTRONTEC's service experience in successful verification and delivery for dozens of leading semiconductor customers. Specifically, GTRONTEC's semiconductor team includes over 400 semiconductor professionals and a pool of over 500 industry resources with nearly 7 years of industry service and factory validation, continuous R&D accounting for over 50%, and self-controllable AI + CIM + AMHS solutions covering top-level planning, solution formulation, implementation delivery, and post-operation maintenance for smart factories. As of now, practical achievements in the semiconductor field are significant, products and services are in the first tier, PMO project management achieves 0 delays, 0 unfinished projects, 100% delivery success rate, customer repurchase rate as high as 70%.

Customers choose to partner with GTRONTEC as the service leader, besides valuing the adaptability and advancement of GTRONTEC's QMS solution, more importantly, value GTRONTEC's service experience in successful verification and delivery for dozens of leading semiconductor customers. Specifically, GTRONTEC's semiconductor team includes over 400 semiconductor professionals and a pool of over 500 industry resources with nearly 7 years of industry service and factory validation, continuous R&D accounting for over 50%, and self-controllable AI + CIM + AMHS solutions covering top-level planning, solution formulation, implementation delivery, and post-operation maintenance for smart factories. As of now, practical achievements in the semiconductor field are significant, products and services are in the first tier, PMO project management achieves 0 delays, 0 unfinished projects, 100% delivery success rate, customer repurchase rate as high as 70%.

Recently, GTRONTEC's self-developed "Octopus AI large model platform" officially integrated with DeepSeek V3/R1. After integrating the model, it will in terms of quality management, continuously output AI-generated 8D reports/PFMEA, predict future trends of quality indicators, analyze supplier quality reports, quality knowledge base Agent and other AI tools, bringing new services to empower AI engineering implementation and semiconductor quality management scenarios. In the future, GTRONTEC will continue to promote the AI revolution in multiple industrial scenarios including quality management, bringing profound changes to the supply of AI application services in advanced manufacturing such as semiconductors, scenario intelligence acceleration, and disruption of 'predictive' production methods.

Recently, GTRONTEC's self-developed "Octopus AI large model platform" officially integrated with DeepSeek V3/R1. After integrating the model, it will in terms of quality management, continuously output AI-generated 8D reports/PFMEA, predict future trends of quality indicators, analyze supplier quality reports, quality knowledge base Agent and other AI tools, bringing new services to empower AI engineering implementation and semiconductor quality management scenarios. In the future, GTRONTEC will continue to promote the AI revolution in multiple industrial scenarios including quality management, bringing profound changes to the supply of AI application services in advanced manufacturing such as semiconductors, scenario intelligence acceleration, and disruption of 'predictive' production methods.