[AI Intelligence, Industry First Look] Episode 1 | GTRONTEC × DeepSeek, AI-Driven Intelligent Leap in 8D Reports

In advanced manufacturing fields such as semiconductors and industrial robotics, the 8D report is a core tool for quality management. It provides the 'optimal solution' for various issues related to quality management in production, including supplier, manufacturing, finished product, and after-sales problems. The 8D report not only helps users clarify their thinking but also provides strong support for subsequent solutions, serving as a guideline for quality management. However, the traditional 8D report management model in manufacturing faces severe challenges: inefficient data tracing—quality engineers spend significant time aligning data across systems like MES/ERP/SCM, with manual retrieval error rates remaining high; broken knowledge transfer—the annual loss of tacit experience among quality engineers is high, and it takes new employees several months to independently complete qualified reports; delayed validation of measures—traditional finished product validation cycles are long, and delayed validation of corrective measures leads to recurring problems and significant losses. To some extent, losses due to delayed 8D processing remain high, and quality engineers expend considerable time and effort organizing data, leaving advanced manufacturing constrained by both efficiency and accuracy. Finding a more precise and effective tool for creating 8D reports has become a shared aspiration. Recently, GTRONTEC, as a leading team in industrial AI, officially integrated DeepSeek and showcased the 'fruits of AI intelligence' in industrial scenarios, defining a new technical path for the next generation of after-sales 8D reports:

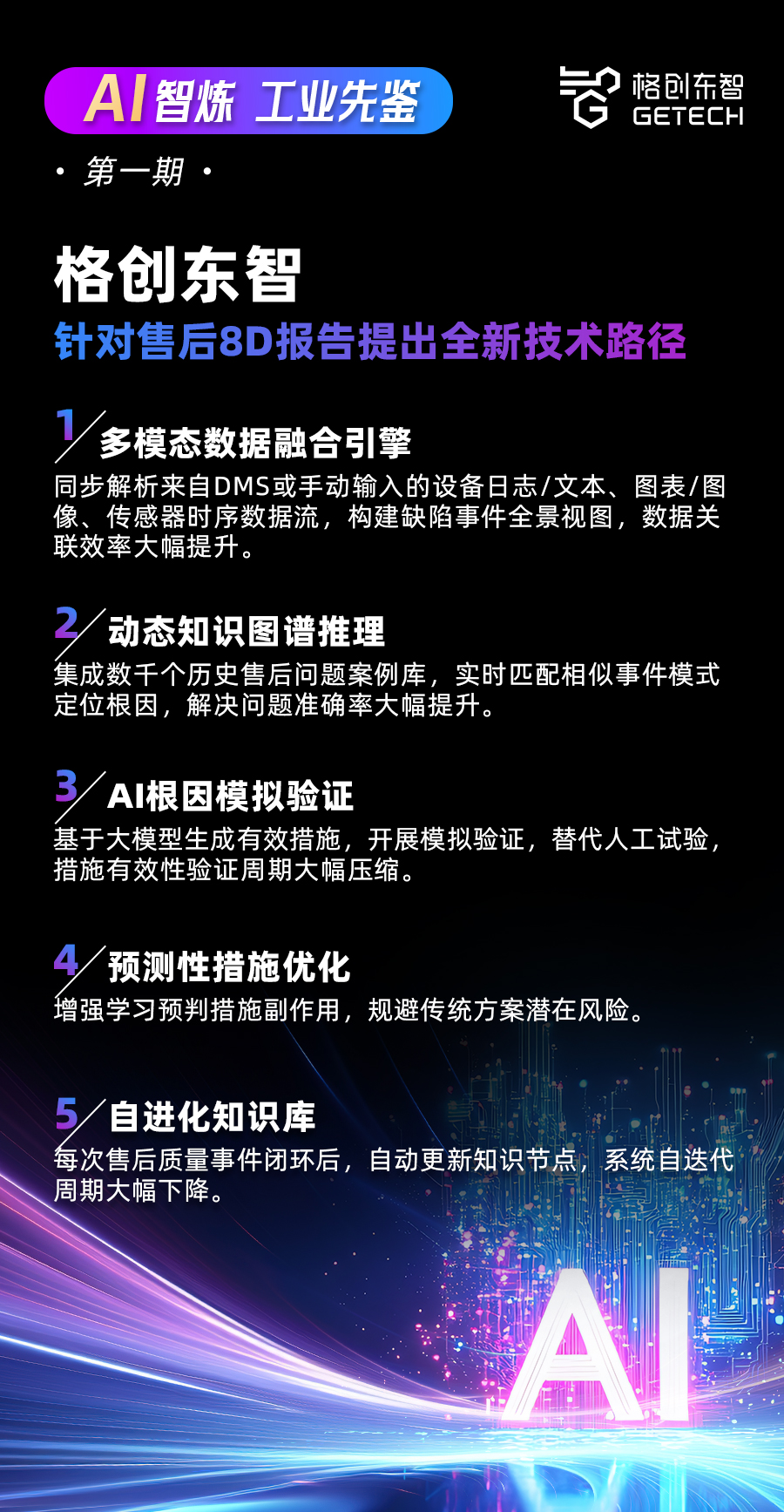

Recently, GTRONTEC, as a leading team in industrial AI, officially integrated DeepSeek and showcased the 'fruits of AI intelligence' in industrial scenarios, defining a new technical path for the next generation of after-sales 8D reports:

Recently, GTRONTEC, as a leading team in industrial AI, officially integrated DeepSeek and showcased the 'fruits of AI intelligence' in industrial scenarios, defining a new technical path for the next generation of after-sales 8D reports:

Recently, GTRONTEC, as a leading team in industrial AI, officially integrated DeepSeek and showcased the 'fruits of AI intelligence' in industrial scenarios, defining a new technical path for the next generation of after-sales 8D reports: