[AI Intelligence, Industry First] Episode 2 | GTRONTEC & DeepSeek: AI Large Model Operations Indicator Management System Breaks Through Management Challenges

For CEOs, after setting annual strategic business goals and breaking them down into various business domains, they often care about several questions: How to predict whether the strategic goals will ultimately be achieved? Are there risks that the business objectives may not be met? Can interventions be made in advance to mitigate these risks? When business strategic goals are passed down to various business domains and further broken down into tasks for different units, executives such as CFOs, CTOs, CHOs, CSOs, COOs, and CMOs also face similar concerns. As business objectives are pushed down to specific production lines, factory workshop supervisors encounter various bottlenecks when breaking down production requirements and allocating targets. These include difficulties in dynamically adjusting production plans, delays in production data feedback, inefficient cross-departmental resource coordination, mismatches between personnel skills and tasks, and complexities in quality control and traceability. These issues lead to a lack of effectiveness in frontline production data. Deviations in frontline production data can trigger a butterfly effect, directly impacting the group's operational indicator management. This results in poor data monitoring timeliness, insufficient decision-making basis, difficulties in execution tracking, business process breakpoints, and cross-level coordination barriers, ultimately leading to inefficient operations and financial "bleeding." Therefore, enterprises are attempting to build a unified AI operations indicator management system to introduce a precise production "baton" for business operations. As a leading industrial intelligence solutions provider, GTRONTEC has embedded AI into its product and service matrix over the past six years, refining more effective services to support the "digital blue sky" of advanced manufacturing. From GTRONTEC's perspective, these challenges can be overcome with a shift in mindset. The company's self-developed AI large model operations indicator management system aims to help manufacturing enterprises transition from digital operations to AI-driven intelligent data operations. The system quantifies operational goals across business domains and departments from the strategic level to the execution level. Through a unified AI large model operations indicator management system, customers can operationalize their goals and process data, enabling real-time control and preemptive interventions to ensure the achievement of ultimate strategic objectives. Notably, the system now integrates large models and traditional AI algorithms, supporting innovative features such as AI conversational creation, definition, and query of indicators, intelligent analysis, and automated report generation. This is designed to reduce labor costs, identify business improvement opportunities, and support customers' transition from leadership-driven and function-driven to data-driven operations.

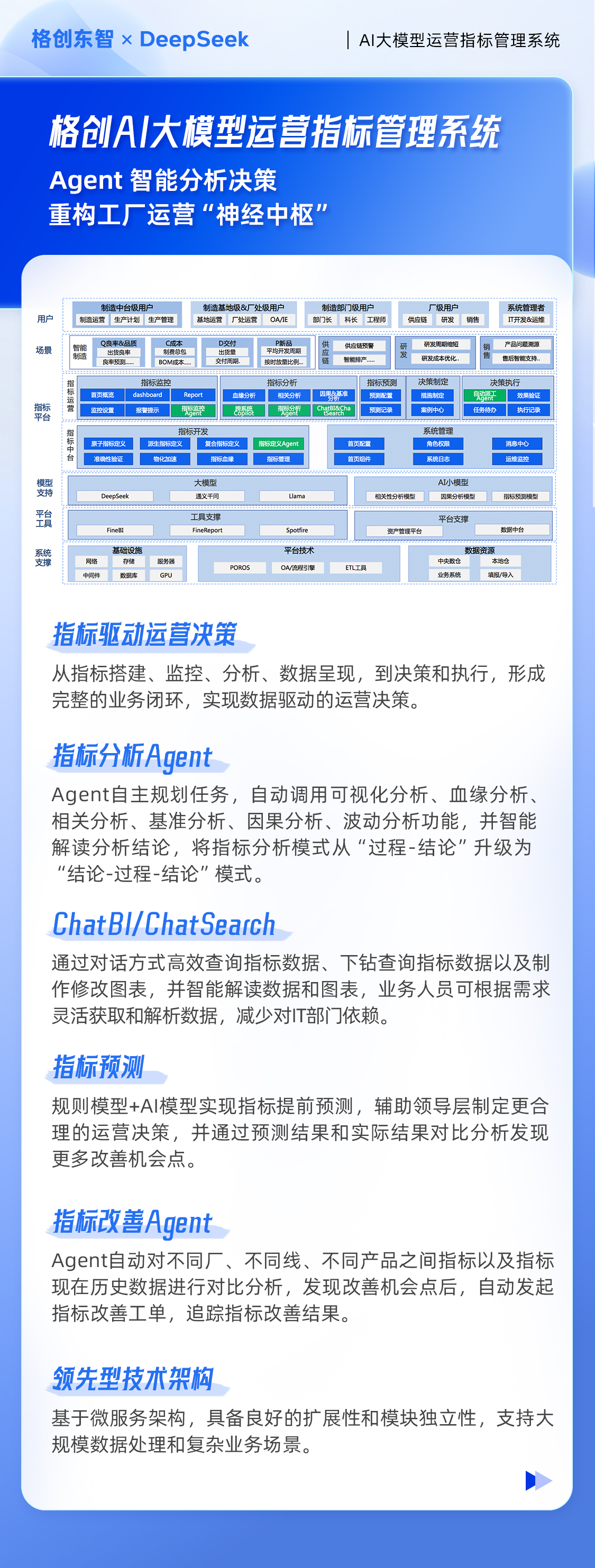

As a leading industrial intelligence solutions provider, GTRONTEC has embedded AI into its product and service matrix over the past six years, refining more effective services to support the "digital blue sky" of advanced manufacturing. From GTRONTEC's perspective, these challenges can be overcome with a shift in mindset. The company's self-developed AI large model operations indicator management system aims to help manufacturing enterprises transition from digital operations to AI-driven intelligent data operations. The system quantifies operational goals across business domains and departments from the strategic level to the execution level. Through a unified AI large model operations indicator management system, customers can operationalize their goals and process data, enabling real-time control and preemptive interventions to ensure the achievement of ultimate strategic objectives. Notably, the system now integrates large models and traditional AI algorithms, supporting innovative features such as AI conversational creation, definition, and query of indicators, intelligent analysis, and automated report generation. This is designed to reduce labor costs, identify business improvement opportunities, and support customers' transition from leadership-driven and function-driven to data-driven operations.

To date, GTRONTEC's AI large model operations indicator management system has established "business command centers" for hundreds of pan-semiconductor factories, demonstrating significant advantages in addressing various operational challenges:

As a leading industrial intelligence solutions provider, GTRONTEC has embedded AI into its product and service matrix over the past six years, refining more effective services to support the "digital blue sky" of advanced manufacturing. From GTRONTEC's perspective, these challenges can be overcome with a shift in mindset. The company's self-developed AI large model operations indicator management system aims to help manufacturing enterprises transition from digital operations to AI-driven intelligent data operations. The system quantifies operational goals across business domains and departments from the strategic level to the execution level. Through a unified AI large model operations indicator management system, customers can operationalize their goals and process data, enabling real-time control and preemptive interventions to ensure the achievement of ultimate strategic objectives. Notably, the system now integrates large models and traditional AI algorithms, supporting innovative features such as AI conversational creation, definition, and query of indicators, intelligent analysis, and automated report generation. This is designed to reduce labor costs, identify business improvement opportunities, and support customers' transition from leadership-driven and function-driven to data-driven operations.

As a leading industrial intelligence solutions provider, GTRONTEC has embedded AI into its product and service matrix over the past six years, refining more effective services to support the "digital blue sky" of advanced manufacturing. From GTRONTEC's perspective, these challenges can be overcome with a shift in mindset. The company's self-developed AI large model operations indicator management system aims to help manufacturing enterprises transition from digital operations to AI-driven intelligent data operations. The system quantifies operational goals across business domains and departments from the strategic level to the execution level. Through a unified AI large model operations indicator management system, customers can operationalize their goals and process data, enabling real-time control and preemptive interventions to ensure the achievement of ultimate strategic objectives. Notably, the system now integrates large models and traditional AI algorithms, supporting innovative features such as AI conversational creation, definition, and query of indicators, intelligent analysis, and automated report generation. This is designed to reduce labor costs, identify business improvement opportunities, and support customers' transition from leadership-driven and function-driven to data-driven operations.

To date, GTRONTEC's AI large model operations indicator management system has established "business command centers" for hundreds of pan-semiconductor factories, demonstrating significant advantages in addressing various operational challenges: