From Single-Factory Control to Group-Wide Monitoring: Greatech FDC Solution Redefines New Paradigms for Equipment Intelligence Control—Replication

With the deepening development of the semiconductor industry, leading companies have established multi-Fab collaborative layouts. However, FDC systems across factories face challenges:

With the deepening development of the semiconductor industry, leading companies have established multi-Fab collaborative layouts. However, FDC systems across factories face challenges:

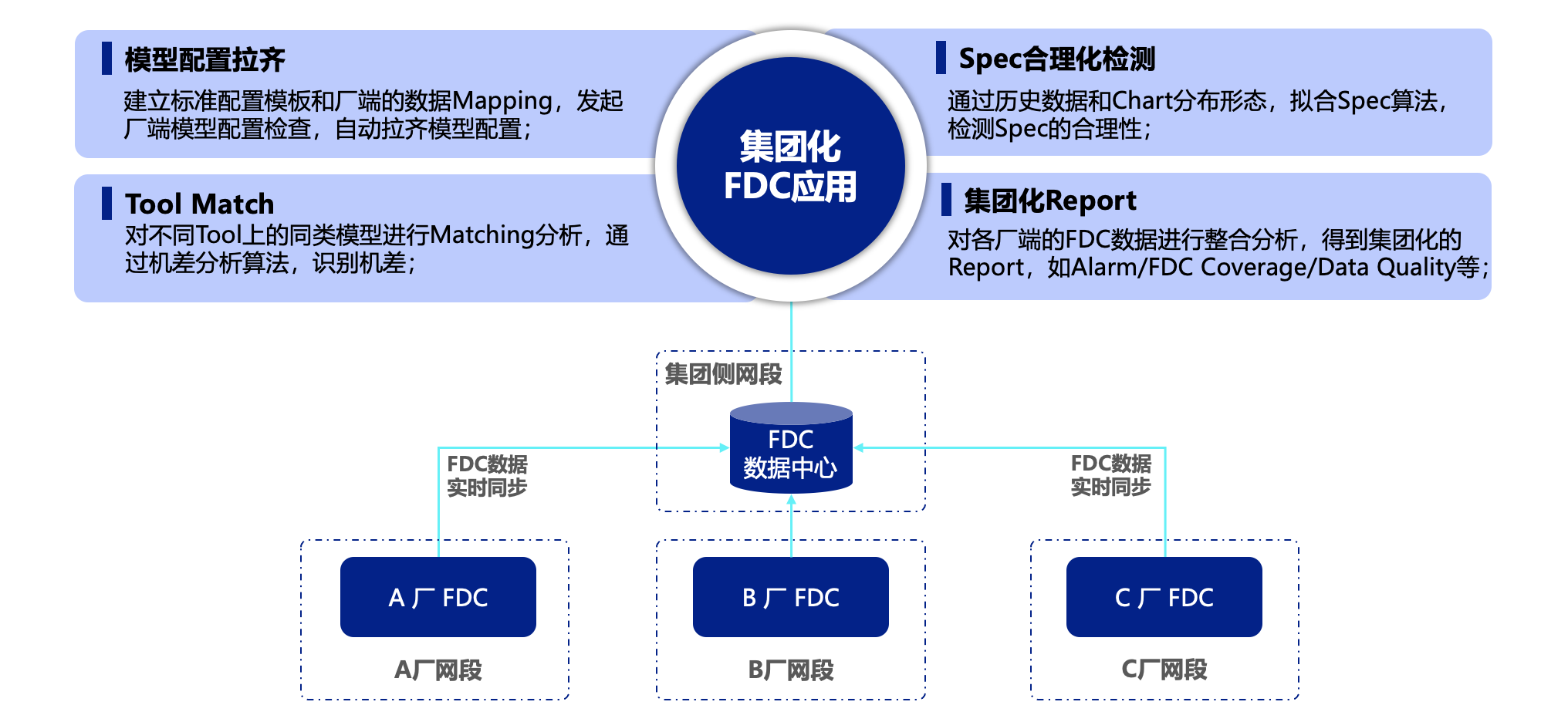

Group-Wide FDC Solution

Transforming Cross-Factory Semiconductor Equipment Monitoring from 'Reactive Firefighting' to 'Comprehensive联防'

1. Multi-factory data fragmentation: Legacy FDC systems cannot compare equipment parameters across factories, leading to inefficiencies in规格优化 (Spec Tighten) and差异分析 (Tool Matching). 2. Equipment failures and false alarms: Legacy systems based on static rules have high false alarm rates and cannot adapt to dynamic process parameter changes. 3. Inconsistent model configuration standards:跨Fab厂 FDC parameter standards are not unified, resulting in low management efficiency. 4. Inefficient machine difference analysis: Similar equipment model parameters across Fabs cannot be compared for差异分析, affecting production consistency and stability. Against this backdrop, leveraging deep understanding of semiconductor manufacturing scenarios and its FDC product strengths, Greatech addresses key customer pain points with its group-wide FDC solution. It introduces three core values—group deployment, AI-driven差异分析, and high compatibility—to pioneer a new paradigm in equipment intelligence control for advanced manufacturing.

Group-Wide FDC Solution

Group-Wide FDC Solution

Breaking Cross-Factory FDC Silos, Building a Group-Wide Equipment Intelligence Control Hub

1. Group Deployment, Establishing a Collaborative Management System (1) Cross-Fab data management: Real-time synchronization of FDC data from all factories to the group platform, achieving millisecond-level response to equipment indicator anomalies; (2) Standardized configuration alignment: Establishing mapping rules for process types, sensor naming, etc., on the group FDC platform, automatically detecting and correcting over 90% of non-standard configurations; (3) Intelligent规格优化 management: Using historical data fitting algorithms to dynamically recommend optimal control limits, significantly improving anomaly detection rates while reducing无效告警.

2. AI-Driven差异分析, Precisely Preventing Hidden Machine Difference Risks (1)差异分析 matching engine: Through trend matching, distribution comparison, performance verification, and process tracing, achieving 360° equipment status evaluation; Machine learning实时优化 models大幅降低误报率; (2) AI decision support: Automatically triggering alerts when equipment mean values shift, quickly locating the root cause of machine differences.

3. Seamless Compatibility with Third-Party FDC, Forming a Centralized Management Cockpit (1) 100%兼容第三方FDC,无损数据接入, providing group-wide reports; (2) Cross-factory third-party FDC data integration and analysis, generating group-wide reports; (3) Unified standard configuration templates, automatically checking and correcting model configurations across multiple FDC systems, enhancing management efficiency.

Typical Scenarios

Group-Wide FDC Solution: From Single Factory to Group, Enabling Digital Collaboration to Cover Every Equipment's 'Lifeline'

1. Multi-factory equipment collaboration: Enterprises need跨Fab厂 FDC parameter comparison and analysis to achieve group-level规格标准化. 2. Complex process optimization: In scenarios like different front-end manufacturing, multi-factor system analysis is required to improve anomaly interception efficiency. 3. Third-party system adaptation: Seamlessly migrating original FDC modeling data, providing localized functions like OA approval and闭环管理. 4. Real-time production保障: Addressing hidden issues like equipment power outages and process interruptions with system platform秒级报警.

Industry Benefits

Group-Wide FDC Solution 'FDC Super Brain' Meets Group-Wide Equipment Continuous Production Needs

1. Efficiency improvement: Enabling group-wide data integration and analysis, unifying跨厂 FDC models, reducing configuration synchronization time from weeks to hours,大幅减少人力投入. 2. Cost savings: Group FDC cockpit, utilizing big data analysis for fault prediction and差异分析, reducing equipment downtime losses and大幅减少设备维护成本. 3. Intelligent upgrade: Group-wide FDC system integrating AI technology improves response speed and accuracy, advancing manufacturing from 'report management' to 'cognitive decision-making'.

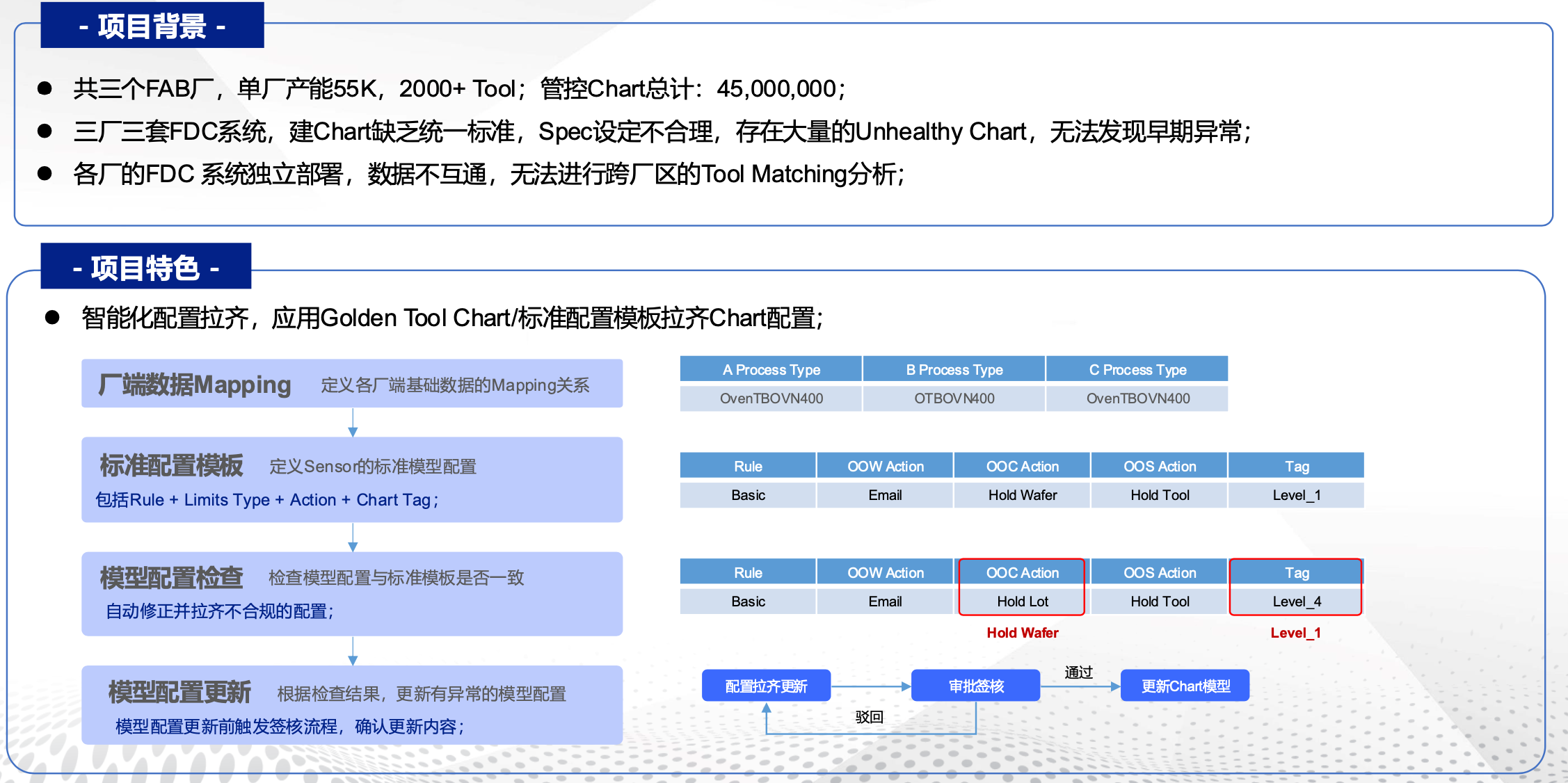

Customer Case Study

In serving a leading 12-inch Wafer Fab Cross Fab client, Greatech addressed challenges like isolated operation of third-party FDC systems across three Fabs, poor collaboration, and inability to gain a holistic view of cross-factory equipment status. Greatech deeply analyzed the client's situation, providing a group-wide FDC solution to help establish an enterprise-level FDC management platform for跨厂设备差异分析和规格优化.

Helping the client achieve:

Helping the client achieve:

1. Unified standards: Successfully established cross-factory FDC parameter standard configuration templates, achieving consistency across all factory FDC system configurations.

2. Machine difference analysis: Through big data analysis, identified and resolved multiple equipment machine difference issues, improving production consistency and stability.

3. Intelligent management: Utilizing AI technology, realized intelligent management of the FDC system, significantly enhancing the accuracy of fault prediction and diagnosis.

4. Efficiency improvement: Through group-wide FDC data integration and analysis, generated group-wide reports such as Alarm/FDC Coverage/Data Quality, significantly improving management efficiency.

As the first industrial intelligence solutions provider in China to launch a group-wide FDC solution, Greatech's confidence stems from over 40 years of know-how in the pan-semiconductor industry, practical empowerment 'from industry, to industry,' and a commitment to understanding customer needs, investing in product R&D, and strengthening solution capabilities. Focusing on the semiconductor industry as a strategic priority, Greatech consistently tackles challenging yet right tasks, internalizing 'first principles' to deliver end-to-end services from smart factory顶层规划,方案制定, implementation, and后期运维. To date, it has successfully assisted dozens of leading semiconductor clients in achieving full-factory digital transformation, covering stages like civil construction, capacity ramp-up, and expansion, and has repeatedly been recognized as an excellent partner by clients. Moving forward, the company will continuously iterate and upgrade its service matrix for semiconductor manufacturing, leveraging AI and large model technologies to focus on AI general platform service tools and AI algorithm innovation, enhancing core CIM systems like MES, EAP, FDC, RMS, QMS, AMHS solutions, and end-to-end smart factory digital upgrade services. It aims to lead the普及与应用 of AI in the semiconductor industry, accelerating advanced manufacturing into the AI era.