Digital Intelligence Base, AI Empowerment: How QMS Opens a New Chapter in Quality Management?

As a key part of the core competitiveness of manufacturing enterprises, quality management is of great significance for improving production efficiency, reducing costs, and enhancing market competitiveness. Currently, the wave of digital transformation in manufacturing is sweeping across, with enterprises facing both external pressures and internal challenges. With the upgrading of customer demands, intensifying market competition, and accelerating technological upgrades, traditional quality management models are increasingly unable to meet the continuous requirements of "improving quality, reducing costs, and increasing efficiency", and there are the following pain points:

Data "silos", discrete businesses: Traditional quality management relies on manual records and分散的系统, leading to quality data分散 across different departments or links, inefficient business processes, difficulty in closing the quality management loop, lack of quality control throughout the product lifecycle, and difficulty in achieving full value chain integration;Poor human efficiency, resource waste: Inefficient processes such as manual scheduling, sampling inspection, and supplier assessment, with a disconnect between systems and execution, resulting in repetitive non-value-added data editing and reporting work, and unregulated/unexecuted double work costs;

Insufficient business depth and span: Quality-related records or simple processes exist in ERP (Enterprise Resource Planning System) and MES (Manufacturing Execution System), but effective analysis and cross-business domain flow are lacking; quality analysis remains at basic levels like Max, Min, Ave, unable to perform professional predictions;

Difficulty in reusing experience, data cannot support decision-making: Inability to effectively reuse historical problem experiences, lack of modular analysis in product design, inability to accurately push formed experiences, data acquisition relying on post-event investigations, and business decisions based on experience rather than data support;

Lag in process changes and risk control: Frequent adjustments in advanced processes, but traditional management relying on manual experience struggles to timely correlate equipment parameters, material batches, and quality results, unable to quickly attribute yield fluctuations;

Lack of intelligent analysis capabilities: Failure to deeply and effectively mine quality data, absence of predictive analysis tools, unable to provide early warnings for potential risks;

These pain points constrain the agility of quality improvement in manufacturing enterprises. In this context, the Quality Management System (hereinafter referred to as QMS) becomes key to breaking the deadlock.

Compared to management systems like ERP and MES, which only handle "partial" quality informatization, QMS is more targeted, comprehensive, mature, and systematic. Its core advantage lies in breaking the information "silos" of quality data across different systems, forming an effective closed loop, enabling group-wide and product lifecycle quality management, and through data collection and entry, deeply mining and summarizing originally discrete and implicit quality data to provide effective data support for lifecycle quality control.

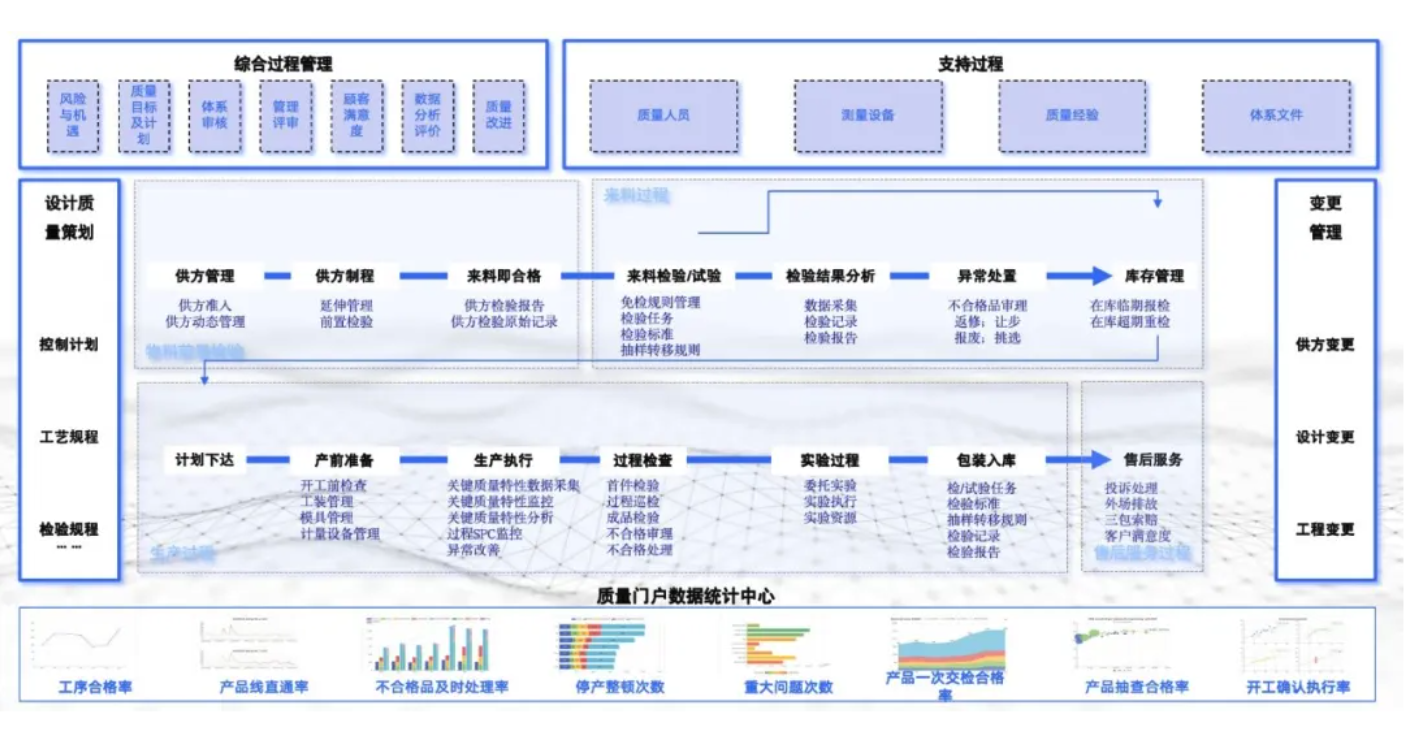

Vertically, it integrates the quality information chain from the group, subsidiaries, business units, to factories; horizontally, it coordinates the quality business chain across R&D design, procurement, incoming materials, production, testing, and after-sales; externally, by cooperating and supplementing with systems like ERP and MES, through integrating data and processes, it achieves networked quality work, effective closed loop of collaborative quality events, intelligent application of quality information, and full sharing of quality experience,全面提升 enterprise quality management and product quality levels.

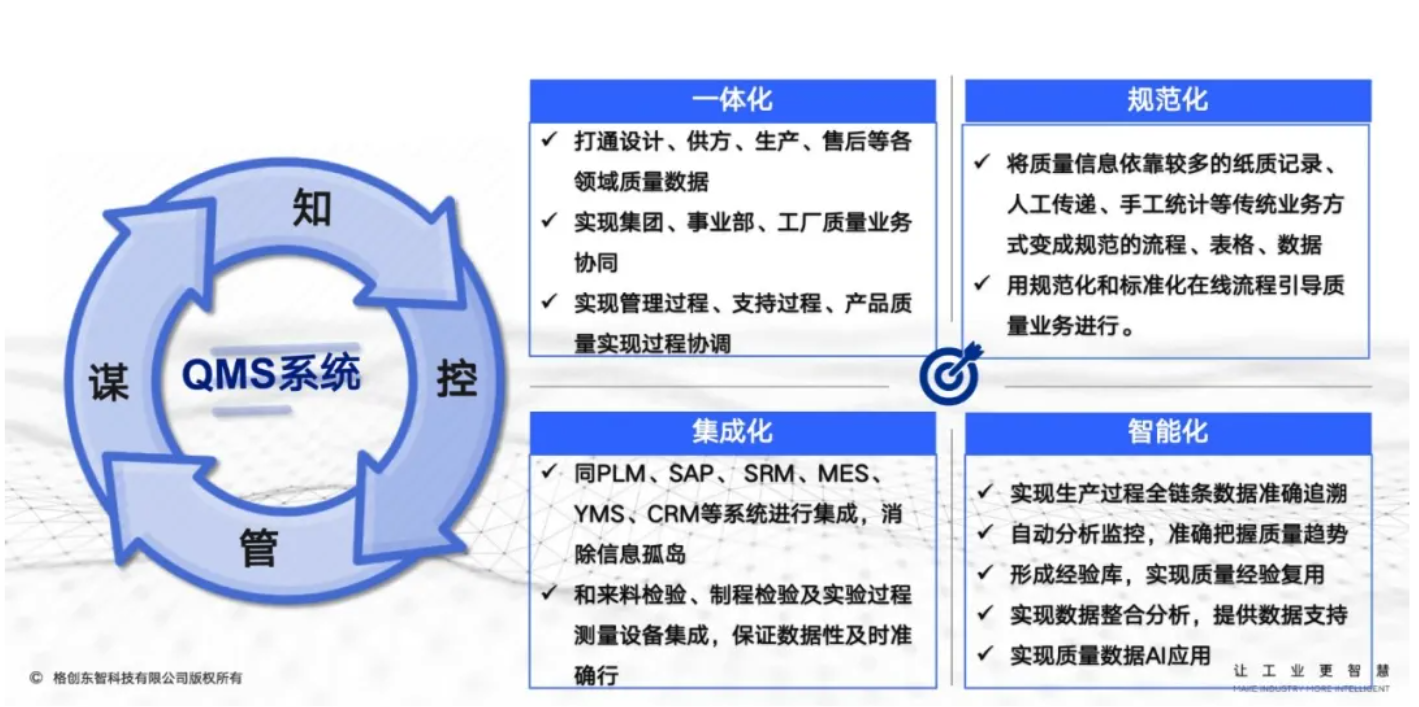

QMS, based on management requirements of systems like ISO9000/IATF16949/GJB9001C, covers the management processes, product realization processes, and support processes of the quality management system, focusing on an integrated, standardized, and intelligent decision support platform for the entire product lifecycle, helping enterprises improve quality indicators and reduce quality costs, empowering digital transformation of enterprise quality management through quality business optimization and management digital upgrade.

With the leapfrog development of AI technology and the continuous promotion of the "AI + Manufacturing" initiative, dual drivers from both technology and policy are助推 QMS integrating AI as a new trend in quality management development. The combination of QMS and AI, by introducing AI large models and machine learning technologies, can effectively empower intelligent quality inspection and predictive quality management,推动 AI quality revolution. For example, using computer vision + deep learning algorithms can accurately identify and classify product defects; through AI + big data predictive analysis capabilities, it can help enterprises predict potential quality issues, achieving "preventive" error correction. In AI-integrated quality management, GTRONTEC combines AI algorithms and big data to actively empower product quality identification analysis and equipment fault diagnosis prediction. Based on the deeply integrated DeepSeek "Octopus Intelligence" Agentic AI platform and comprehensive AI tools, using AI Agent to automatically generate 8D reports, it shows outstanding performance in generation timeliness, data correlation efficiency, root cause定位 accuracy, measure generation effectiveness, problem recurrence rate, knowledge inheritance, and quality management cost reduction.

GTRONTEC QMS is an important part of the company's "Comprehensive Quality" solution, adhering to the concept of全员,全过程,全生命周期, covering over 10 functional modules including quality专项工作, quality knowledge management, metrology equipment management, R&D quality management, supplier quality management, incoming material quality management, process quality management, after-sales quality management, continuous improvement management, full lifecycle tracking and tracing, and quality tools (APQP, PPAP, SPC, MSA, FMEA, CP), integrating the full-chain quality information flow from R&D design, incoming inspection, production manufacturing to after-sales service. Currently, it has successfully served multiple industries including semiconductor, new energy, automotive parts, 3C electronics, and consumer goods.

In the era of accelerated intelligent transformation in manufacturing, enterprise quality management urgently needs change. Using QMS to promote quality business optimization and management digital upgrade can help enterprises grasp the forefront of quality management digitalization, continuously integrate industrial AI with quality management practices, open a new chapter in intelligent quality management, and build sustainable quality competitiveness for manufacturing to navigate周期波动.