Success Story | GTRONTEC's CIM Solution for MEMS Top 10 Enterprise in Building a Digital Smart Factory

With the company's rapid business growth, the original MES production management system revealed increasing issues:

Over a dozen workshops operated independently, making cross-workshop production management difficult;

Data from various test equipment, including CP, could not be extracted and analyzed, hindering quality improvement;

Multi-segment management from wafer to die led to challenges in plant-wide production data statistics and precise full-process traceability from production to warehousing;

Production quality monitoring was inefficient, with delays in test result judgments and low efficiency in process parameter collection and data analysis;

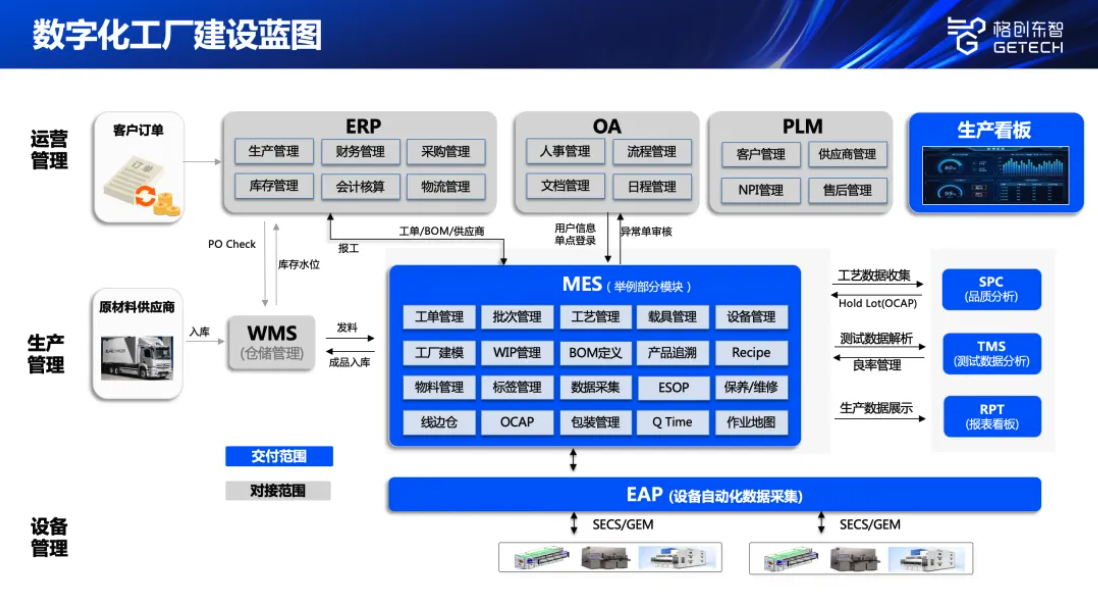

1) Plant-wide MES management and cross-workshop information flow: For multi-workshop operations, a plant-wide MES system was implemented with data models segmented by workshop, supporting batch tracking across workshops and providing workshop-specific production dashboards for clear visibility.

1) Plant-wide MES management and cross-workshop information flow: For multi-workshop operations, a plant-wide MES system was implemented with data models segmented by workshop, supporting batch tracking across workshops and providing workshop-specific production dashboards for clear visibility.

2) Equipment data collection/parsing for quality improvement: EAP system accurately collects test equipment data, parsing and storing it in real-time or offline; combined with TMS, it reads and displays test data to users for problem analysis, process optimization, and quality enhancement.

3) Full-process traceability and production visualization: Customized features and integration with ERP and WMS enable segmented management with end-to-end data traceability from wafer to die. Custom reports and dashboards provide plant-wide production statistics and workshop visualization.

4) Real-time quality monitoring: SPC system enables real-time quality control throughout production, improving efficiency and product quality.

GTRONTEC's plant-wide CIM solution centers on production operation management, integrating order management, production execution, quality control, equipment management, and operational decision-making with industrial automation (including equipment networking and data collection) into a unified manufacturing management platform. It enables closed-loop control of the entire manufacturing process, with large-screen dashboards for workshop visualization, creating a digital, transparent, and automated smart factory.

1. 100% process and quality traceability

Through plant-wide MES, equipment file parsing, and custom features, achieve end-to-end batch traceability.

2. Production efficiency increased by over 15%

Streamline workshop operations and data, break down system barriers, and improve execution efficiency.

3. Human-error quality incidents reduced by over 95%

Significantly reduce quality issues caused by misoperation, Q-Time overtime, recipe errors, and material misuse, improving yield and capacity.

4. Equipment OEE improved by 20%

Analyze equipment OEE via MES and machine data, optimizing production planning and equipment utilization.

5. Yield increased by over 20%

Monitor and analyze production quality with TMS and SPC systems to enhance product yield.

6. Production costs reduced by over 10%

Manage inventory across line-side warehouses with transparent stock information and traceable material history.