Co-author of AII Dual Carbon Blue Book, Gechuangdongzhi Uses AI to Outline Industrial 'Digitalization and Greenization' Transformation Blueprint

Recently, the 2025 Industrial Internet Conference 'Industrial Digitalization and Greenization Collaborative Transformation Forum' was grandly held in Suzhou, attracting experts and representatives from government, industry, academia, research, and application sectors to gather together, exploring paths for deep industry empowerment from a multi-collaborative perspective. Gechuangdongzhi was invited to attend, and Wang Hui, General Manager of the Energy Dual Carbon Business Department, delivered a keynote speech titled 'AI Empowers High-end Manufacturing Dual Transformation Collaborative Transformation', discussing with frontline enterprises like Tailingfu, Hegang Digital, Huawei Technologies Co., Ltd., etc., around cutting-edge technological progress and practical achievements of industrial dual transformation collaboration, focusing on transformation pain points to contribute innovative wisdom.

In the theme sharing session, Wang Hui, based on Gechuangdongzhi's participation in compiling the Industrial Internet Industry Alliance (hereinafter referred to as 'AII') 'Carbon Peak and Carbon Neutrality Blue Book (2025)' (hereinafter referred to as AII Dual Carbon Blue Book), deeply dissected the blueprint planning and implementation paths of digitalization + greenization 'dual transformation' management.

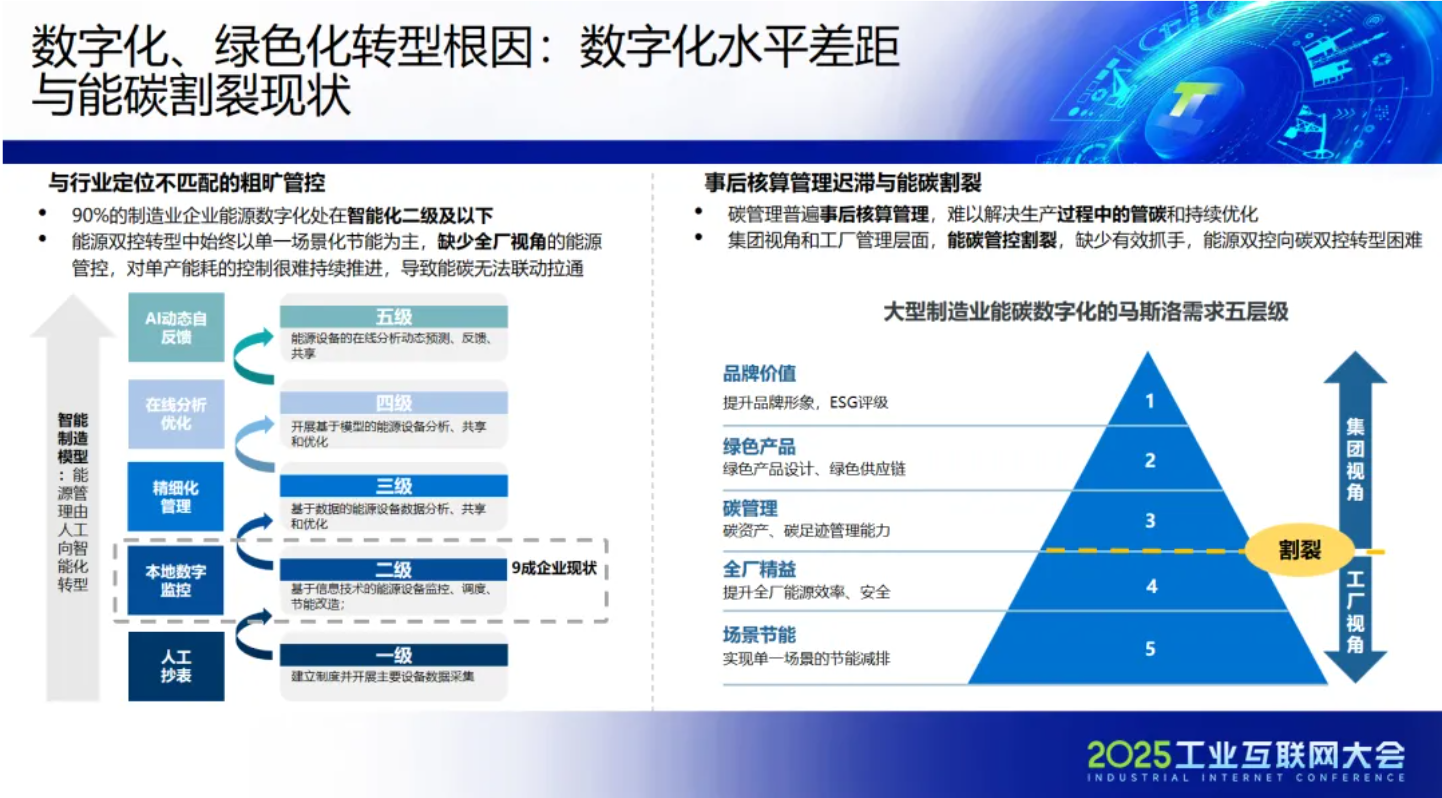

According to his judgment, the energy dual transformation in manufacturing is facing the challenge of parallel digital upgrade and energy-carbon control with system fragmentation. 90% of enterprises focus on single-scene energy saving, lack a whole-plant perspective, and cannot link single production energy-carbon, presenting a rough control status that does not match industry positioning. At the same time, carbon management is accounted for afterwards, making it difficult to solve carbon management and continuous optimization in the production process; at the group level and factory management level, the fragmentation of energy-carbon control leads to a lack of effective handles, and the transformation from energy dual control to carbon dual control is difficult.

High-end manufacturing dual transformation is a comprehensive, systematic, and long-term construction process, covering from single factories to entire chain ecosystems achieving zero-carbon operation, etc., requiring all-round changes from enterprise products, manufacturing processes, production processes, carbon emission control to industry collaboration. Facing transformation difficulties, Wang Hui proposed five feasible paths: for enterprise products, conduct green design and low-carbon innovation; for manufacturing processes, carry out process revolution to break the 'high-precision-high-energy consumption' shackles; for production processes, spread management scenarios with multi-end coverage; for carbon emission control, ensure data transparency and footprint traceability; for industry collaboration, exert benchmark effects to radiate the industry.

The AI wave is surging forward, bringing new perspectives to energy refined management. At the meeting, Wang Hui also combined Gechuangdongzhi's years of scene practices in AI+ energy-carbon management, detailing how to maximize energy-carbon value based on AI. As an industrial intelligence leader incubated by TCL, Gechuangdongzhi has accumulated rich dual-carbon practices in the pan-semiconductor field. Its self-developed factory AI energy-carbon brain and solutions have achieved full coverage of energy-carbon digital management in over ten factories under TCL. At the same time, it has been promoted to over 70 manufacturing factories in 20+ industries including the pan-semiconductor field, forming a closed loop of 'endogenous practice-technology precipitation-cross-industry empowerment'. For example, Gechuangdongzhi's multi-agent AI energy-carbon brain system, combined with real-time multi-modal data collection from the factory system, helped a certain new energy battery leader's base achieve annual energy savings of over one million yuan, with a comprehensive energy saving rate of over 10%. Another example is using AI data models + mechanism models to break through digital empowerment applications in single energy-saving scenes. In a certain semiconductor customer practice, facing key high-energy consumption scenes like HVAC systems, using digital tools and cutting-edge technologies such as AI and big data, achieved energy consumption savings, improved management efficiency, annual energy saving and consumption reduction of over ten million yuan, and carbon asset surplus of over one million yuan.

The achievement of dual-carbon goals is a cross-field, multi-dimensional systematic project, inseparable from the active exploration and practice of government, industry, academia, and research sectors. It is noteworthy that as a leading dual-carbon innovation enterprise with deep capabilities, Gechuangdongzhi,凭借AI赋能高端制造业节能减碳的先进实践, became one of the main co-author units of the AII Dual Carbon Blue Book. During the blue book compilation process, Gechuangdongzhi refined paradigms, contributing from the industry side highly referential and reusable industry methodologies and action coordinates for achieving dual-carbon goals, constructing a complete panoramic framework of 'strategic insight + scene practice + industry empowerment + future outlook'.

Dual transformation is the key to breaking through new industrialization. In the future, Gechuangdongzhi will tirelessly run at the forefront of the dual-carbon transformation industry, riding the wind of AI to forge a new chapter of dual transformation collaboration, continuously exploring new paradigms of 'digital-green integration', and accelerating the new stage of 'dual transformation' development in advanced manufacturing.