[AI+CIM Solutions] No.1|AI Reconstructs CIM, GTRONTEC Launches First CIM AI Foundation, Lowering Industrial Agent Usage Barrier

In semiconductor manufacturing, with the industrial software 'big housekeeper' CIM covering all aspects of wafer production, originally independent systems such as MES, EAP, MCS, YMS, etc., form a collaborative and more powerful new system, helping chip production meet the requirements of low fault tolerance and high software stability.

With the rapid development of large model technology, AI has become an important auxiliary productivity tool and work partner. Mastering the application ability of large model tools is becoming a key competitiveness for semiconductor companies to enhance CIM value. But how can large model tools break through data silos and the traditional CIM constraint of 'human-driven connections' through knowledge extension and intelligent collaboration? How can they lead innovation and transformation in semiconductor manufacturing with a new form of CIM?

Based on these questions, GTRONTEC CTO MK Koh earlier proposed the 'Semiconductor CIM Evolution Path,' defining the direction of next-generation CIM. In his view, the core of CIM evolution is transitioning from 'experience-driven' CIM to a 'data-driven + AI collaborative' CIM intelligent decision-making hub. This relies on the deep integration of large model agents with enterprise-level data, business processes, and system tools, reconstructing CIM from 'designed for people' to 'designed for responsibilities.'

What is 'responsibility-designed' CIM? MK Koh gave a detailed technical explanation: a CIM that understands 'responsibilities' will, based on given goals, find ways, tools, and step-by-step complete tasks. It is an active 'digital employee' network that perceives the environment, makes decisions, and takes action. Here, 'responsibility-designed' CIM is the brain, and multiple agents are the hands and feet. Each agent, as a 'digital employee,' actively calls APIs of different CIM subsystems to obtain information and execute tasks when realizing a lack of information to fulfill responsibilities. This vision is becoming a reality in GTRONTEC's recently developed CIM AI Foundation.

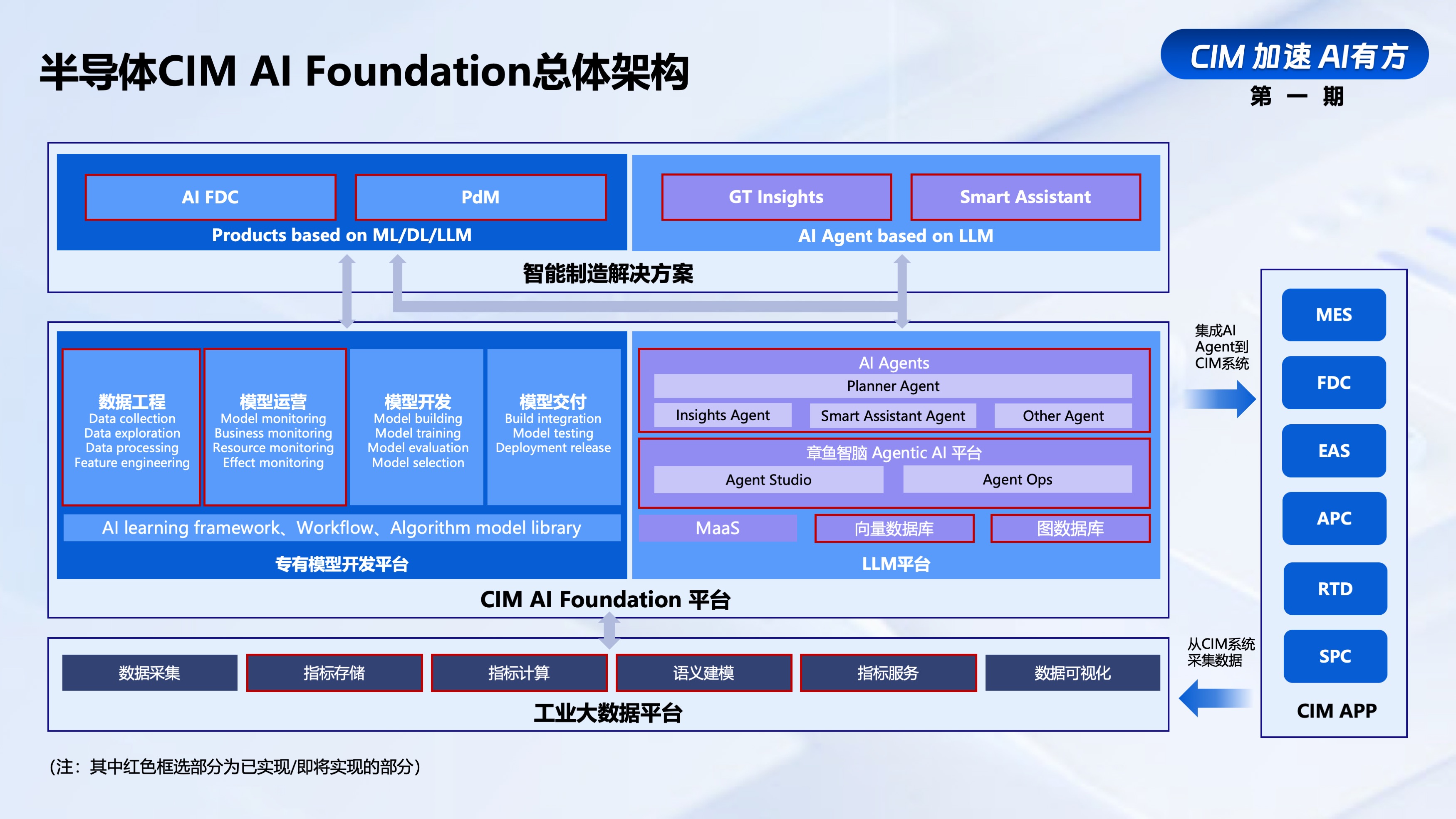

As an industrial AI leader originating from TCL and strategically focused on semiconductors, the company recently completed a major R&D upgrade of its CIM AI Foundation. It redefined the 'AI foundation' of semiconductor CIM at the architectural level, achieving systematic breakthroughs from data intelligence and model development to agent applications, and systematically building a multi-agent system platform. Multiple agent systems include main control agents, sub-agents, reference assistants, memory systems, tool sets, and other 'responsibility' virtual roles. Using a 'coordinator × worker' model, through division of labor and collaboration, like a real team, they solve complex problems that are difficult for a single entity to complete efficiently through clear role division and parallel processing. It can turn a complex task into a collaborative, iterative, and scalable task network, truly realizing the paradigm shift from 'human-driven systems' to 'AI-driven systems.'

The core positioning of GTRONTEC's CIM AI Foundation is an 'integrating and empowering' AI middleware. It integrates multi-agent systems, connecting and integrating massive heterogeneous data generated by traditional CIM systems such as MES, EAP, APC, FDC, breaking system barriers and building a unified, clean, real-time high-quality data lake. Upwards, it provides 'plug-and-play' models and services for various intelligent applications through standardized, modular AI capability interfaces. This means that if a semiconductor smart factory needs to develop an AI Agent, whether it is a yield analysis assistant or an equipment predictive maintenance assistant, it no longer needs to start from scratch but can quickly call the algorithm components, model services, and knowledge base capabilities encapsulated in the middleware like building blocks.

Notably, this AI middleware already supports different agent platforms and assistants participating in collaborative evolution.

01 Octopus Agentic AI Platform 3.0

Used for agent development and empowerment, it provides low-threshold/no-code visual orchestration and AI Agent digital employee building tools, while supporting the full lifecycle management process of AgentOps, including Agent testing, tuning, and release. It covers over 100+ Agent tools for automatic report generation, tracing abnormal Loss, etc.

02 GT Insights

Used for semiconductor factory data analysis and insights, it supports intelligent interaction and insight into business indicators. Based on powerful semantic modeling technology, it transforms complex database fields into business indicators that business personnel can understand. Using natural language queries, it can self-parse intent, generate SQL, execute queries, and visualize results, while supporting the dynamic generation of complex Dashboards, compressing traditional data extraction and analysis work that took hours to minutes. It now includes dozens of yield analysis workflows optimized for semiconductor scenarios, enabling one-click root cause tracing of yield, reducing expert dependency, and shortening analysis task time to minutes.

03 Xiaoluban and AI FDC product family's intelligent parameter selection, intelligent alarm classification, and many other Agent applications

Used for equipment predictive maintenance, building semiconductor factory knowledge bases, and operational assistants. AI FDC can accurately detect faults and clearly inform 'why abnormal' and 'related to which defects,' with online learning for continuous evolution. Xiaoluban AI Agent is used for knowledge inheritance and operational assistance. Based on a multi-modal document parsing engine, it supports a dual-engine knowledge base system combining vector and graph databases for performance and accuracy, transforming tens of thousands of unstructured knowledge items in the factory into queryable, inferable, and executable structured knowledge bases. Through terminals like AR glasses, it intuitively pushes maintenance guides and operational steps to engineers, significantly reducing training costs and misoperation risks for equipment management personnel.

GTRONTEC's latest R&D upgrade has positioned it as a pioneer in China's CIM industry by exploring the productization of multi-Agent concepts. The deeper value lies in its systematic establishment of a continuously evolving, open, and collaborative AI ecosystem within the semiconductor CIM field—a first in the industry. This ecosystem not only addresses current challenges such as redundant development and operational costs caused by "siloed development" but also, through its Agent framework, equips future smart factories with the capability for "intelligent derivation" and "autonomous evolution" to adapt to new processes, equipment, and challenges. In the future, every new CIM task can be transformed into reusable models or workflows, contributing to the collective intelligence of the entire factory. From a broader perspective, this architectural innovation significantly lowers the barrier to implementing AI applications, enabling semiconductor enterprises to rapidly build proprietary intelligent capabilities. Simultaneously, through knowledge accumulation and autonomous evolution mechanisms, smart manufacturing systems truly become continuously appreciating assets.

China's semiconductor intelligent manufacturing is moving from 'automation' to the deep water of 'intelligence,' competing not only in the intelligence of hardware equipment but also in the soft power of deeply integrating data, knowledge, algorithms, and business scenarios. The launch of GTRONTEC's CIM AI Foundation undoubtedly provides the industry with a solid, open, and future-oriented reference answer.