GTRONTEC Speaks at CIIF, Unlocking the Path for Industrial AI Implementation

On September 24, the Shanghai National Convention Center was bustling with crowds, and the 25th China International Industrial Fair was in full swing. At this global industrial event with the theme 'Industrial New Quality, Smart Manufacturing Without Borders', GTRONTEC's Marketing Director Yang Li was invited to attend the 'AI New Smart Manufacturing, Technology New Era' forum on AI empowering smart manufacturing technology development, sharing the stage with executives from companies like Omron, Advantech, and Inovance Technology to discuss ways to break through in industrial intelligence implementation.

Yang Li pointed out that industrial AI implementation needs to overcome multiple challenges such as data, models, cost, and engineering. To address this, GTRONTEC proposed the 'ABCDE' industrial AI implementation framework, covering Algorithm, Big Data, Computing, Domain knowledge, and Equipment across five dimensions, systematically advancing the closed-loop implementation of AI technology in complex industrial scenarios. Yang Li emphasized that only enterprises with domain knowledge and equipment experience in specific industrial sectors can integrate data, algorithms, and computing power to ground industrial intelligence, meeting the extreme demands of advanced manufacturing in stability and accuracy.

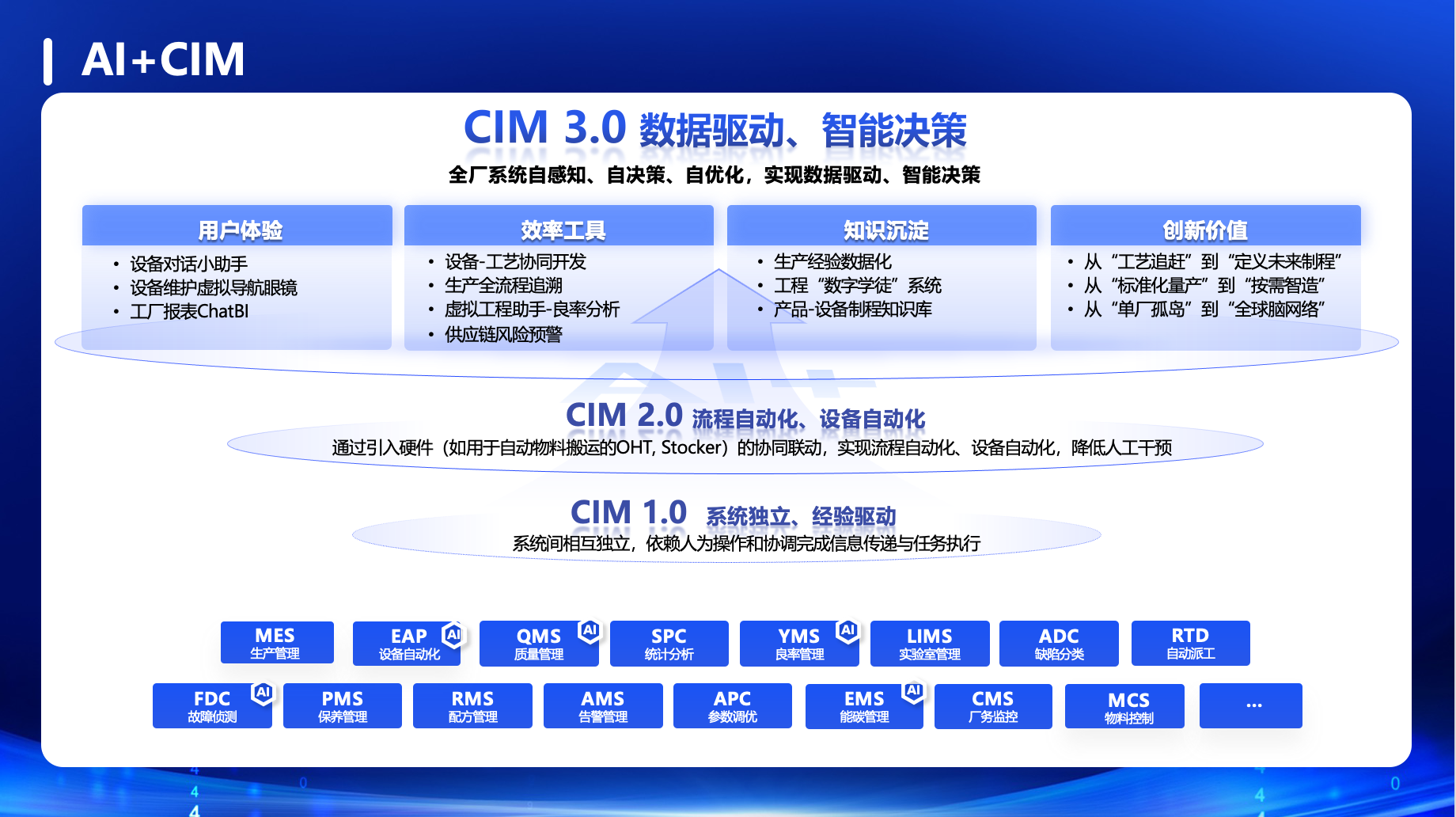

GTRONTEC has always focused on the semiconductor industry as a strategic area, and based on the 'AI+CIM+AMHS' integrated software-hardware industrial intelligence solution, it helps the semiconductor industry achieve production goals of 'high rhythm, zero defects'. At the soft power level of AI empowerment, Yang Li revealed the evolution path of industrial AI-driven semiconductor CIM, indicating that semiconductor CIM is transitioning from 'experience-driven' to 'data-driven + AI collaboration', relying on the deep integration of large model agents with enterprise-level data, business processes, and system tools to accelerate the arrival of next-generation CIM.

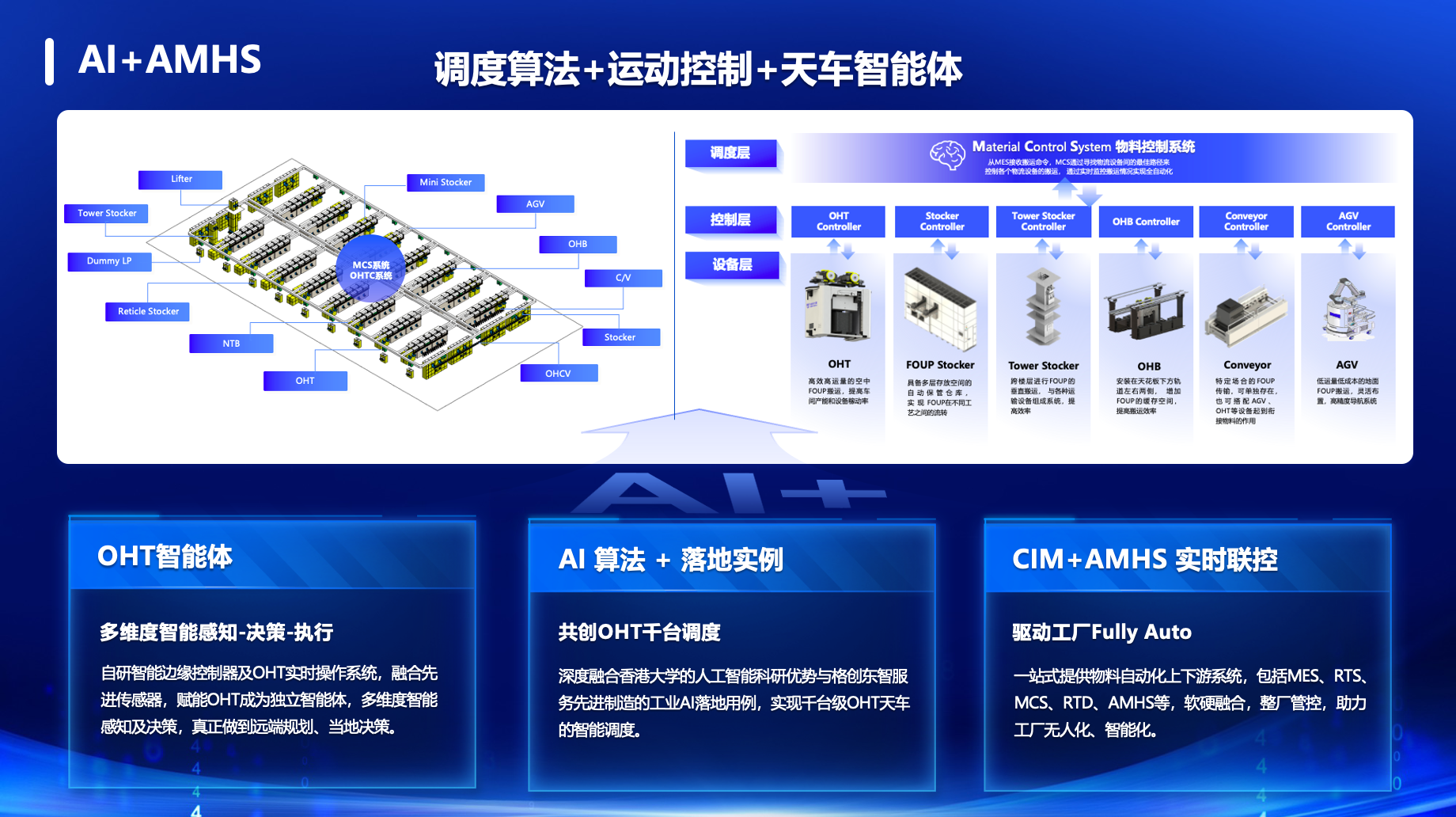

At the hard power level, GTRONTEC is accelerating the deep integration of industrial AI with hardware equipment. In core scenarios of semiconductor material handling, GTRONTEC's independently controllable AMHS solutions, represented by OHT (Overhead Hoist Transport) and Stocker, have secured several major Chinese semiconductor clients. Based on the first-phase project of the Hong Kong University-GTRONTEC Industrial Joint Laboratory, they co-developed intelligent scheduling models that perceive and integrate MES, MCS business data, and OHTC operation data, forming highly business-aware AMHS solutions, aiming to break through in the core area of thousand-unit OHT scheduling algorithms. Clearly, the integrated software-hardware capability is GTRONTEC's core advantage distinguishing it from pure software vendors.

Additionally, as an industrial AI leader strategically incubated by TCL, GTRONTEC focuses on the 'AI+Industrial Software+Smart Equipment' strategic framework, accumulating rich typical cases across multiple scenarios in TCL's various industries. Yang Li shared that in serving TCL CSOT, a leader in semiconductor display, the company achieved deep industrial AI empowerment based on smart application scenarios across five digital platforms: R&D, supply chain, product, sales, and ERP. In quality management scenarios, GTRONTEC uses AI industrial vision inspection systems to automatically detect, classify, and handle defects, increasing defect detection accuracy to 95%. In product R&D scenarios, GTRONTEC collaborates with TCL industries, using knowledge graphs and vector retrieval technology to integrate massive process documents, equipment parameters, and anomaly records into a 'virtual expert system', addressing core needs such as intelligent Q&A, new employee training, product issue analysis, and document assistance in the display field, helping engineers provide reliable knowledge Q&A and decision support, with document summarization efficiency improved by 60% and product issue analysis efficiency by 20%.

Notably, ETECH recently launched the CIM AI Foundation multi-agent system platform, providing comprehensive industrial agents and large model tools for CIM systems, lowering the barrier to integrating large model technology into CIM systems, and accelerating cost reduction and efficiency improvement in semiconductor manufacturing. In practical applications, the platform's GT Insights conversational ChatBI function saves 90% of data query, analysis, and interpretation time; the AI-enhanced group FDC solution helped a leading semiconductor enterprise achieve cross-factory equipment difference analysis and specification optimization.

GTRONTEC's voice at the CIIF represents a company's technological confidence. Its deep empowerment of TCL's internal industries has become a microcosm of Chinese manufacturing moving from 'scale' to 'quality'. It not only provides the industry with a reusable methodology for industrial AI implementation but also uses the CIIF as a window to showcase to the world China's path for industrial intelligence moving from 'concept first' to 'value practice' in a new stage.

As a leading enterprise in industrial intelligence, GTRONTEC continues to chart a benchmark path for China's industrial intelligence development through its integrated 'AI+Industrial Software+Smart Equipment' capability, helping Chinese manufacturing establish a voice in the global smart manufacturing competition.