How Stocker Achieves Full-Link High-Efficiency Collaboration and Builds Intelligent Logistics in Semiconductor Factories

In the semiconductor AMHS automated material handling system, Stocker is not an isolated 'material warehouse' but a key node connecting hardware like OHT/AGV and software like MCS/RTD/MES. Its collaboration capability directly determines the overall efficiency of AMHS and even affects the entire factory's capacity and yield.

Efficient collaboration between Stocker and AMHS relies on hardware docking, software interaction, and algorithmic decision-making, which break down 'equipment silos' to achieve full-link efficient collaboration and build an intelligent logistics network.

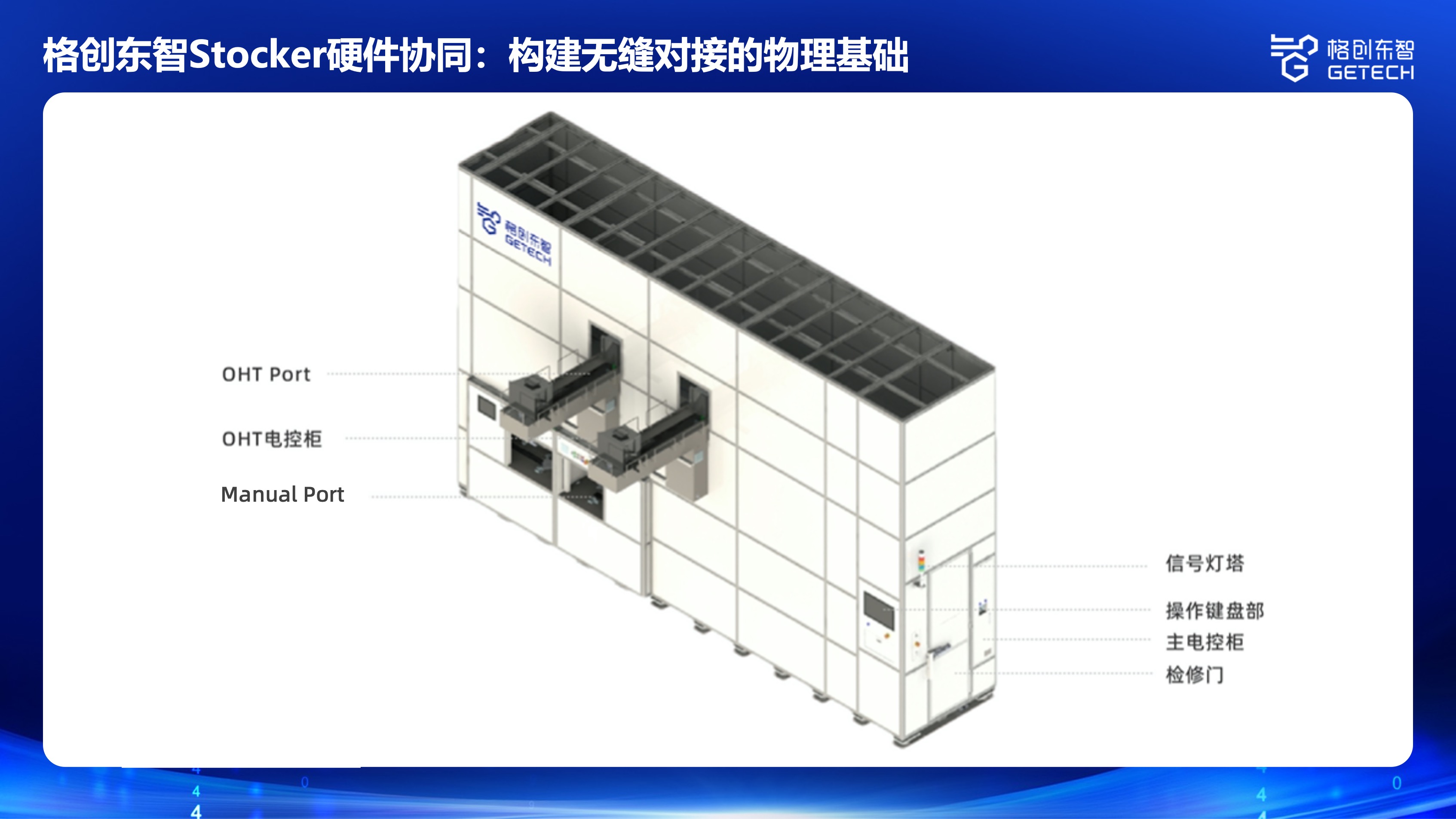

1. Hardware Collaboration: Building a Seamless Physical Foundation

Stable physical connections are the premise of full-link collaboration. Stocker ensures 'seamless docking and zero-interruption collaboration' with the AMHS system through standardized interfaces, multi-carrier compatibility, and full-status sensing.

Standardization + Redundant Interfaces: Solving 'Docking Compatibility' Pain Points

Interface standardization: Stocker can be equipped with various interfaces like OHT Port, Manual Port, AGV Port, and CV Port, all using SEMI-standard mechanical structures and electrical protocols to avoid collaboration interruptions due to incompatibility;

Key interface redundancy: Critical interfaces like OHT Port and AGV Port can switch between Input/Output functions; a single port failure does not affect overall logistics, ensuring continuous system operation.

Multi-Carrier Intelligent Compatibility: Adapting to Full-Process Material Forms

Intelligent carrier recognition: Stocker integrates visual recognition (OCR/BCR) and RFID technology to automatically identify different carriers like FOUP (wafer boxes), Trays, and Cassettes;

Customized grasping: Robotic arms can be equipped with customized grippers, designed based on carrier type and specifications to meet full-process material handling needs from front-end manufacturing to back-end packaging and testing.

Real-Time Data Collection + Alerts: Preventing Single Points of Failure in Advance

Distributed sensor network: Stocker can be configured with sensors for temperature, humidity, pressure, etc., based on storage environment requirements, to collect internal environmental data in real time;

Predictive maintenance: Intelligent analysis based on equipment operating parameters and other data provides early warnings of mechanical failures, avoiding unplanned downtime.

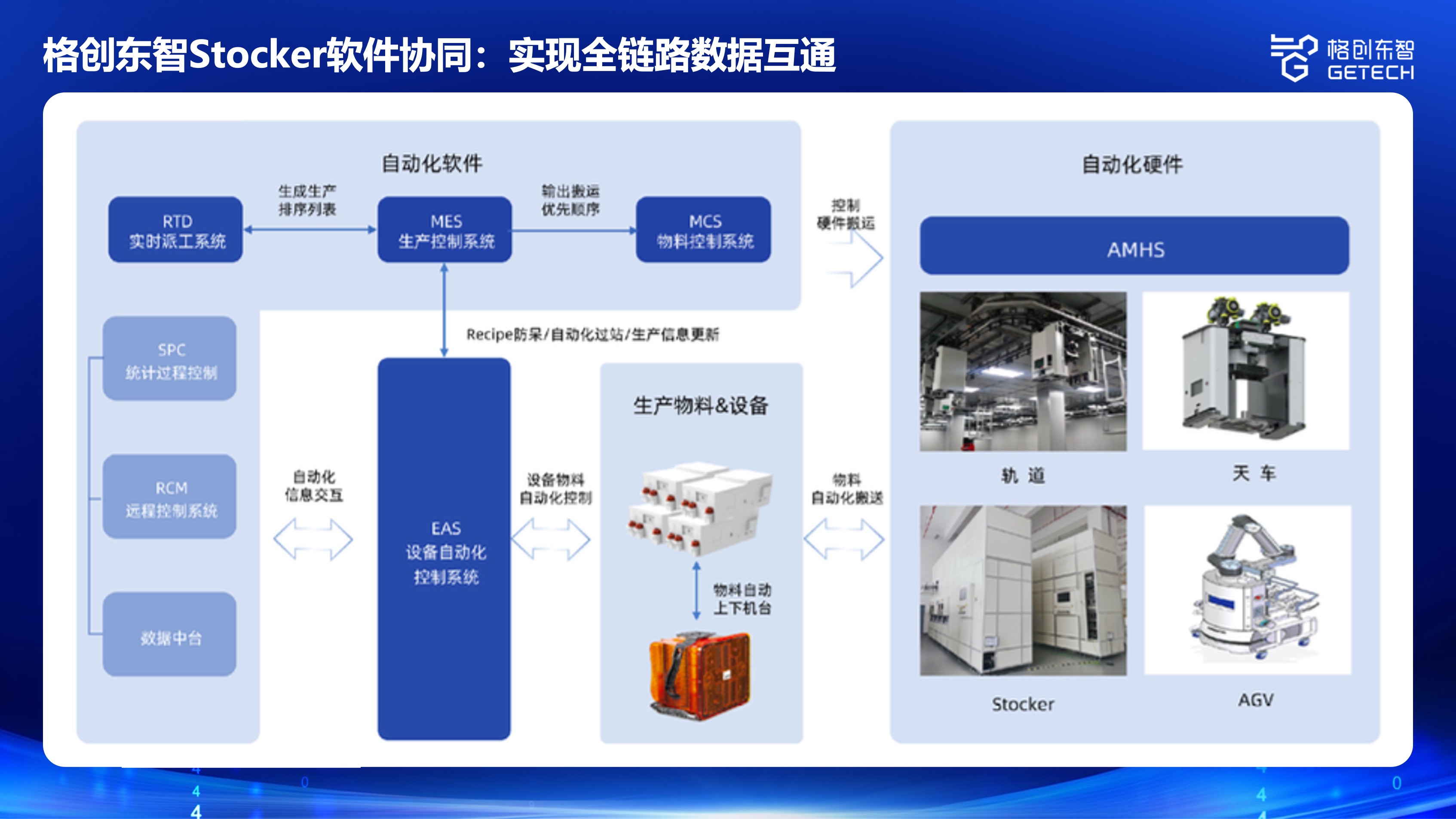

2. Software Collaboration: Achieving Full-Link Data Interoperability

After hardware connection, unified 'communication language' is needed for data interaction. The SECS/GEM protocol, as the 'common language' of semiconductor equipment, supports deep collaboration between Stocker and systems like MCS, RTD, and MES.

Collaboration with MCS (Material Control System)

Information synchronization: Stocker reports its inventory map, storage location status, equipment status, etc., to MCS in real time, allowing MCS to build a global material perspective and know 'which materials are where';

Task execution: MCS issues 'store/retrieve' tasks to Stocker based on MES work order instructions; Stocker feeds back results to MCS after execution;

Congestion avoidance: When MCS detects multiple OHTs queuing at a Stocker entrance, it can dynamically assign tasks to other idle Stockers for load balancing.

Collaboration with RTD (Real-Time Dispatch System)

Intelligent predictive scheduling: RTD predicts the next batch of material demand time based on equipment production rhythm and instructs MCS to schedule Stocker in advance;

Dynamic path optimization: Real-time analysis of the entire factory's logistics status dynamically adjusts material access priorities and path planning, achieving an advanced collaboration mode of 'materials waiting for machines'.

Collaboration with MES (Manufacturing Execution System)

Work order and material binding: When MES issues a work order, it simultaneously transmits information like Lot number and process parameters to Stocker; Stocker binds the work order to the carrier via RFID, ensuring 'each storage location corresponds to a unique work order' to avoid mixing risks;

Yield data feedback: Stocker uploads material storage duration and environmental parameters (e.g., oxygen concentration, temperature, humidity) to MES; if a batch of wafers has abnormal storage conditions, MES can trace the batch's yield data to assist in analyzing yield loss causes.

3. Algorithm Collaboration: The Intelligent Core of Global Optimization

True efficient collaboration is not just 'responding to instructions' but 'proactively optimizing'. Stocker enhances the global efficiency of the AMHS system through inventory optimization algorithms, digital twin simulation, and other technologies.

Dynamic Inventory Optimization Algorithm: Improving Access Efficiency

Adaptive storage location allocation: Dynamically calculates the optimal storage location based on multiple factors like material priority, destination, and equipment status;

Proximity + priority dual strategy: Assigns materials about to be shipped out to the 'fast shipping area' (near the OHT port), high-priority work order materials to the 'priority storage area', and low-frequency access materials to the 'deep storage area', improving space utilization and shipping efficiency.

Digital Twin Simulation: Virtually Verifying and Optimizing Collaboration Strategies

Virtual debugging: Simulates Stocker operation in a virtual environment through digital twin technology to verify collaboration logic in advance;

Stress testing: Simulates collaboration scenarios during peak periods to verify Stocker interface capacity and MCS scheduling capability, identifying bottlenecks early and optimizing track layout and task allocation strategies;

Forward-looking planning: Adjusts system configuration based on simulation results to avoid congestion and bottlenecks in actual operation.

GETECH Stocker's Collaborative Innovation

In the AMHS collaboration field, domestic Stocker companies break international monopolies with 'customization, high cost-effectiveness, and rapid response', with GETECH's practices being highly representative.

Full-Link Collaboration Solution: Avoiding Multi-Vendor Interface Barriers

GETECH provides an 'AI+CIM+AMHS' integrated solution, with Stocker deeply collaborating with self-developed OHT, MCS, and MES, overcoming multi-vendor system compatibility issues to achieve end-to-end seamless docking.

Core Technology Self-Innovation: Enhancing Collaboration Precision and Efficiency

GETECH Stocker uses self-developed STKC control system, supporting synchronous control of overhead and ground tracks (handling accuracy ±0.5mm), Auto Teaching (automatically acquiring storage location data), with 100% self-developed software architecture, allowing quick customization of collaboration logic based on customer AMHS needs.

Rapid Delivery and Service: Ensuring Quick Production Line Deployment

GETECH Stocker completes project delivery in as fast as 3 months, with 7×24 service response (2-hour response, 4-hour on-site). In a wafer fab AMHS upgrade project, GETECH set an industry record with '15 days to deliver the first device'.

From precise hardware docking, to software data interoperability, and algorithmic intelligent optimization, Stocker efficiently collaborates with every node in the AMHS network, performing a symphony of efficient, reliable, and intelligent logistics automation. In the future, with technologies like real-time digital twin simulation of collaboration scenarios and AI large models optimizing global scheduling, Stocker will further push the boundaries of collaboration efficiency, driving AMHS from 'automation' to 'intelligence'.