AI Technology Drives Intelligent Upgrade of AMHS, Accelerating Localization Process

GTRONTEC has established Wilson Optimus through a strategic acquisition, enhancing its integrated AMHS (Automated Material Handling System) hardware and software capabilities. Particularly through the deep integration of AMHS with CIM systems and the incorporation of AI technology, system efficiency and reliability have been further improved. From the perspective of Wilson Optimus, this article analyzes the logistics upgrade demands in the semiconductor industry, discusses the development of AMHS localization, and explores how AI technology is driving the intelligent upgrade of AMHS.

The Automated Material Handling System (AMHS), serving as the "logistics artery" of semiconductor fabs, provides efficient and stable automatic material transport, significantly enhancing production efficiency, increasing product yield, and reducing human operational errors. Therefore, it is widely used in front-end and back-end semiconductor processes such as silicon wafer plants, wafer fabrication plants, and packaging and testing plants. In recent years, the localization of AMHS has accelerated, with artificial intelligence (AI) technology playing a catalytic role, helping domestic AMHS companies seize market opportunities through product intelligent upgrades.

GTRONTEC Technology Co., Ltd. (hereinafter referred to as GTRONTEC) is an industrial intelligence solutions provider strategically incubated by TCL. In the semiconductor industry, it can provide semiconductor fabs with integrated "AI + CIM + AMHS" hardware and software solutions. In 2024, through a strategic acquisition, it established its new company -- Shanghai Wilson Optimus Intelligent Technology Co., Ltd. (hereinafter referred to as Wilson Optimus). Currently, Wilson Optimus has built a comprehensive AMHS product system including OHT (Overhead Hoist Transport vehicles, commonly known as sky vehicles), Stocker (wafer storage libraries), MCS (Material Control System), OHTC (OHT Control System), STKC control system, etc. In this feature, relevant personnel from Wilson Optimus provided a detailed analysis of the logistics upgrade demands in the semiconductor industry and the innovative development of AMHS technology.

Reporter: First, could you talk about the main changes in manufacturing and logistics upgrades in China's semiconductor industry in recent years?

Wilson Optimus: In recent years, the development path of China's semiconductor industry has undergone a significant shift, moving from comprehensive catch-up to a new stage of technological breakthroughs and comprehensive enhancement of manufacturing capabilities. This is primarily driven by market demand. The rapid development of industries like new energy vehicles, photovoltaics, and 5G in China, coupled with the rapid iteration and application of AI technology across various sectors, has directly led to a surge in chip demand. Influenced by geopolitics, China continues to increase investment in the semiconductor industry, with the growth rate of new fab construction far exceeding the global average.

From the manufacturing perspective, in mature process nodes, 28nm and above chips have achieved mass production and widespread application domestically, with technology and the supply chain becoming mature. Third-generation semiconductors (SiC, GaN, etc.) are developing rapidly, with China at the global forefront in this field. Significant progress has also been made domestically in advanced packaging and testing technologies (such as Chiplet, 3D IC), leading companies rank among the top globally, and their market share is steadily expanding. However, in advanced process nodes (14nm and below), although there have been technological breakthroughs domestically, large-scale mass production is not yet possible due to restrictions on equipment procurement.

From the logistics perspective, as semiconductor manufacturing processes become more advanced and wafers evolve to larger sizes—from early 6-inch fabs to 8-inch fabs, and now 12-inch fabs becoming mainstream—the number of process steps in production lines has multiplied, and the throughput of key tools has increased rapidly. This has made manual material handling between production line equipment a bottleneck constraining production efficiency and quality. The urgent need for logistics automation upgrades in enterprises has led to significant growth in AMHS market demand. However, compared to the substantial improvement in manufacturing capabilities, the development of logistics automation in China's semiconductor industry has been relatively slow.

Reporter: Could you analyze in detail what changes are evident in the demand for domestic semiconductor AMHS?

Wilson Optimus: The most prominent change in the domestic AMHS market is the rapid increase in demand and increasingly widespread application. AMHS has become an indispensable logistics support for 12-inch wafer fabs. With the increasing number of newly built 12-inch fabs in China, the demand for AMHS, as their standard configuration, has surged. Simultaneously, domestic AMHS has made significant technological progress, gradually capturing the market in various fields such as 8-inch fabs and advanced packaging and testing, and beginning to see batch application in 12-inch mature process nodes (≥28nm). It can be said that both demand and supply sides are driving force, promoting further market expansion. Relevant institutions predict that China's AMHS market will exceed 16 billion RMB by 2025, with a CAGR of over 12%.

A second significant change is that customers require AMHS to evolve from performing basic transport to intelligent upgrades. Early AMHS only handled point A to point B transport of FOUPs. Now, deep integration with MES/CIM systems is required to achieve dynamic route optimization and real-time scheduling. This is because as factory production scales up and the number of tools increases, requirements for AMHS efficiency are further heightened, alongside the need for increased system security and reliability. This can be achieved through full-process system simulation, tool layout optimization, track optimization design, intelligent scheduling, intelligent path planning, intelligent traffic management, OHT speed optimization, and other aspects. For example, Wilson Optimus introduces AI algorithms to predict congestion, improving OHT system scheduling efficiency by over 20%.

Furthermore, domestic semiconductor companies have put forward other requirements for AMHS software, such as improved user-friendliness. Foreign companies, due to their earlier establishment and R&D, have seen some technological rigidity, e.g., older software systems and less user-friendly human-machine interfaces. Domestic manufacturers excel in this aspect.

Currently, fabs focusing on 14nm and below have extremely stringent requirements for AMHS stability and security. This market segment is still primarily dominated by Japanese companies. Achieving high-precision, high-reliability scheduling for over a thousand OHTs and efficient collaboration of ultra-large-scale equipment are key challenges that domestic AMHS companies urgently need to break through.

Reporter: What products can Wilson Optimus provide for semiconductor industry customers?

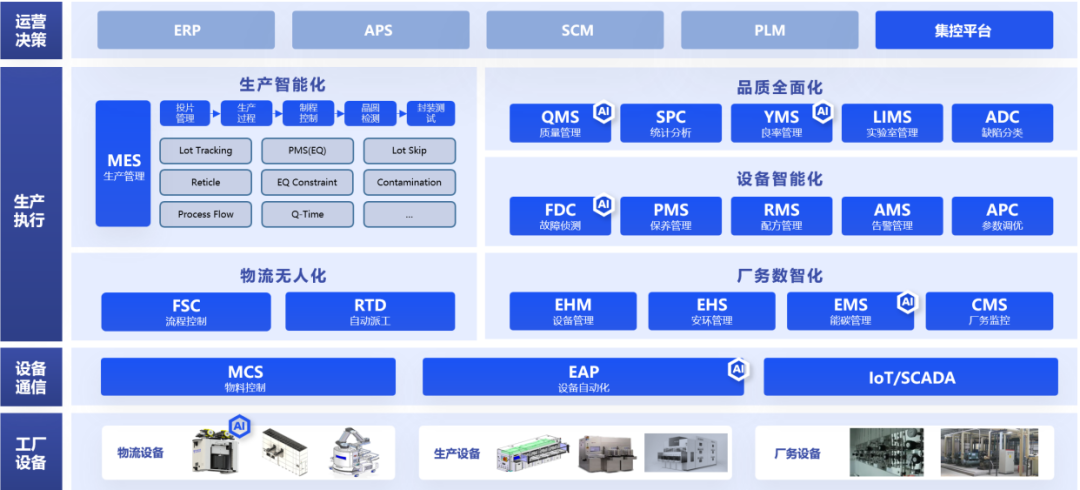

Wilson Optimus: Wilson Optimus's parent company, GTRONTEC, is an AI-driven industrial intelligence solutions provider, offering pan-semiconductor customers integrated "AI + CIM + AMHS" solutions covering manufacturing execution, equipment automation, quality management, energy and carbon management, logistics automation, and digital supply chain functions. AMHS is the core means to achieve unmanned logistics in semiconductor fabs and is regarded as a key part of the solution. To add the hardware component based on the CIM solution, in 2024, GTRONTEC strategically acquired Yunde Co., Ltd. and Jiangsu Ruixinku Intelligent Technology Co., Ltd., merging them to establish its new company, Wilson Optimus. Through resource integration, the AMHS product system was perfected to better help semiconductor industry customers achieve automation, digitalization, and intelligent upgrades.

Currently, Wilson Optimus focuses on AMHS solutions for the semiconductor industry as its core business, while also engaging in warehouse automation and non-standard automation businesses for the pan-semiconductor sector. Wilson Optimus's AMHS solution builds a trinity system of "Software + Hardware + Algorithms":

Hardware: Covers core equipment like OHT and Stockers.

Software: Uses the Material Control System (MCS) as the hub, linking with the Real Time Dispatching (RTD) system and Real Time Scheduling (RTS) system to achieve full-process digital control.

Algorithms: Combined with our self-developed scheduling algorithms, making material handling more precise and efficient.

Wilson Optimus has established strong R&D teams domestically and internationally, achieving multiple technological breakthroughs. For instance, the delivered Tower Stocker and N2 Purge Stocker filled the technological gap for domestic high-end storage equipment; the self-developed wireless power supply system broke the foreign monopoly on this technology; the self-developed OHT controller and OHT operating system enable powerful edge computing capabilities and multi-sensor fusion perception, allowing OHTs not just to passively execute tasks but to complete them more intelligently, safely, and efficiently.

Reporter: You just mentioned that Wilson Optimus's Stocker filled the technological gap for domestic high-end storage equipment. Could you elaborate on this?

Wilson Optimus: Stockers, through fully automated storage, system collaborative scheduling, and high-cleanliness control, bring benefits like yield improvement, efficiency optimization, and cost reduction to production lines, becoming an accelerator for semiconductor intelligent manufacturing. As one of the enterprises in the domestic Stocker field with the "earliest R&D, most complete product variety, and highest shipment volume," Wilson Optimus Stockers have the following advantages:

Full-Scenario Equipment Matrix: Covers intelligent storage for the entire semiconductor process. Wilson Optimus provides Normal Stockers, Tower Stockers, Reticle Stockers, N2 Purge Stockers, as well as supporting equipment like OHBs and NTBs. Options like manual ports/OHT ports/AGV ports/Auto Teaching are available. Through refined hardware and software module combinations and dedicated configuration tools, we quickly respond to customized storage needs.

Rapid Delivery + 7*24 Service: Ensures quick production line deployment and stable operation. Leveraging deep semiconductor industry know-how, strong supply chain support, professional project delivery teams, and installation teams, Wilson Optimus Stockers can achieve equipment delivery in as fast as 2.5 months and installation, debugging, and delivery within 3 months, over 50% faster than international brands (average 6-8 months). Simultaneously, an around-the-clock service mechanism is established, with the fastest response to customer issues within 2 hours and on-site maintenance within 4 hours.

Nearly 100 Units Shipped: Consistently recognized by front-end and back-end customers. From ensuring the storage safety of front-end advanced process wafers to supporting flexible multi-scenario production in back-end packaging and testing, Wilson Optimus Stockers, relying on the core advantages of "technologically self-controlled, deeply scenario-adapted, and efficiently responsive service," have cumulatively shipped nearly 100 units, receiving consistent recognition from front-end and back-end customers. In the future, Wilson Optimus will continue to optimize Stocker performance (e.g., improving handling efficiency, positioning accuracy, safety redundancy) to meet the demands of semiconductor production lines for scaling and automation upgrades.

Deep CIM+AMHS Integration: Drives full factory automation. Wilson Optimus's parent company, GTRONTEC, provides the integrated "AI + CIM + AMHS" solution, offering upstream and downstream logistics automation systems in a one-stop manner, including MES, RTS, MCS, RTD, OHT, Stocker, etc. This avoids interface incompatibility and data flow issues from multiple vendors. Meanwhile, through hardware-software integration and whole-factory control, it achieves data connectivity across the entire "storage-handling-production" chain, helping fabs achieve unmanned and highly efficient operation.

Reporter: How does Wilson Optimus view the role of software in AMHS?

Wilson Optimus: If AMHS is divided into software and hardware, traditionally, software is the decision-making layer of the entire system, and hardware is the execution layer. For example: MCS decides to move a FOUP from point A to point B; OHTC, after receiving the instruction, decides which OHT to dispatch and which route to take for moving the FOUP from A to B; the OHT, after receiving the instruction from OHTC, executes the transport task.

Wilson Optimus has enhanced the edge computing capability and fusion perception capability of OHTs and developed its own OHT operating system, gradually delegating some decision-making power down to the OHT hardware layer. This achieves central planning and remote decision-making, enabling more efficient and safe FOUP transport. The OHT operating system has also become an important part of AMHS software. To use an analogy, it's like sky vehicles driving on tracks. Previously, when crossing intersections, they were controlled by traffic lights (OHTC). After enhancing OHT intelligence, they can exchange information and autonomously decide their travel path, like having a traffic police officer directing at the intersection in real-time, making the system more responsive and efficient.

Reporter: In your view, what impact has AI brought to AMHS?

Wilson Optimus: AI technology undoubtedly has a profound impact on various industries. For semiconductor manufacturing CIM systems, it is undergoing a transition from "experience-driven" to "data-driven + AI-empowered," and a reconstruction from "process automation" to an "intelligent decision-making hub." Similarly, AMHS also involves many important decision-making problems. Adopting AI technology for intelligent upgrades can achieve optimization in the following aspects:

Improving AMHS Efficiency through Full-Process System Simulation and Intelligent Scheduling Algorithms: Based on the analysis of years of operational data, full-fab process flow simulation and AMHS system design optimization can be achieved, including tool layout optimization, OHT track layout optimization, and OHT scheduling optimization, to improve efficiency, enabling the same tasks to be completed with fewer OHTs. Coupled with intelligent scheduling algorithms, the number of OHTs can be further reduced, and traffic congestion decreased, thereby comprehensively enhancing AMHS efficiency. This is Wilson Optimus's unique advantage. Compared to AMHS suppliers who only consider the logistics, we can genuinely consider and connect all aspects of production and logistics from top to bottom based on the CIM system, achieving overall fab design optimization and efficiency improvement.

For example, semiconductor fabs typically have thousands of tools. Through RTD and RTS, if it's found that the quality indicators of certain tools are declining, task allocation to those tools can be gradually reduced. Predictive path planning can also be applied to the OHT system; for instance, if an OHT's operational efficiency is low, it won't be assigned more tasks.

Predictive Maintenance, Enhancing System Reliability: Traditional system maintenance involves periodic equipment inspection. Based on AI + OHTC systems that monitor the status of key OHT components like motors, reducers, and various sensors in real-time, combined with Agent technology, significant improvements in fault warning accuracy and fault analysis and handling efficiency can be achieved, thereby better ensuring stable and reliable system operation.

AI-Assisted Fault Diagnosis: Previously, when faults occurred, experienced senior engineers were relied upon to diagnose and solve the problem. With AI-assisted diagnosis, even novices can resolve faults quickly.

Equipment Intelligence: Besides changes at the software level, the hardware like OHTs, as mentioned before, is also moving towards intelligence. We believe that AMHS intelligence can hardly go far with only software intelligence but without hardware intelligence.

Reporter: In April this year, Wilson Optimus's parent company, GTRONTEC, established a Joint Industrial AI Laboratory with the University of Hong Kong. The first R&D project is achieving precise scheduling of OHTs through AI. Could you talk about the specifics of this project?

Wilson Optimus: GTRONTEC has been deeply involved in Industrial AI for many years and foresaw that AI would bring significant innovation to AMHS. Therefore, it took the lead in establishing the Joint Industrial AI Laboratory with the University of Hong Kong. The laboratory will deeply integrate the University of Hong Kong's strengths in AI research with GTRONTEC's experience in implementing Industrial AI in advanced manufacturing, conducting research in the direction of "Innovation and Practical Application of Industrial AI Technology."

The first R&D project currently being advanced by the laboratory, the AMHS Intelligent Material Handling Scheduling System, specifically targets the industry pain points of domestic AMHS: "insufficient stability and low technological maturity." It aims to accelerate breakthroughs in OHT scheduling AI algorithm technology, achieving intelligent, efficient, and precise scheduling for ultra-large-scale OHT systems with over a thousand vehicles, strongly promoting domestic substitution. The OHT intelligent scheduling model currently under development will achieve the fusion of perception of business data from MES and MCS, and operational data from OHTC, forming a highly business-aware AMHS solution, accelerating the optimization of overall fab efficiency.

AMHS intelligence will be a long-term research topic. Therefore, we have leased new office space at Hong Kong Cyberport, where professors and scholars from HKU, along with R&D engineers from GTRONTEC and Wilson Optimus, conduct research together. The AMHS Intelligent Material Handling Scheduling System has been divided into multiple sub-projects and is progressing in an orderly manner.

Reporter: Finally, could you introduce how Wilson Optimus helps semiconductor companies with logistics upgrades, using typical cases?

Wilson Optimus: Relying on its trinity "Software + Hardware + Algorithms" AMHS solution, Wilson Optimus has served over 50 semiconductor companies, including leading companies in the industry, covering full scenarios from front-end wafer manufacturing to back-end packaging and testing.

For example, in the front-end field, an 8-inch wafer fab of a confidential military unit faced material handling efficiency challenges under multi-tool, complex process flows. We deployed a domestically developed "MCS + OHT + Track + OHB" system, enabling automatic wafer transfer between different process steps, completely eliminating errors and delays from manual handling, and solidifying the logistics foundation for stable and efficient production line operation. In a leading 12-inch wafer fab, the Stocker automated storage solution we delivered not only met high cleanliness and high-security requirements but also set an industry record with the speed of "delivering the first unit within 15 days." Behind this is our deep understanding of semiconductor processes and strong supply chain support.

In the back-end packaging and testing field, we also have benchmark cases. In a leading packaging and testing company, addressing its logistics digitalization upgrade needs, we provided a one-stop hardware and software solution including MCS, RTD, and Stocker, creating a fully unmanned logistics system for the entire factory, becoming a model for large-scale automation application in the packaging and testing industry. It is worth mentioning that for special storage needs, our self-developed N2 Purge Stocker can maintain a Class 100 ultra-clean environment in real-time, features anti-vibration design ≤0.5G, and can achieve "lights-out operation" through automatic barcode scanning and AGV coordination, eliminating risks from human intervention at the root, which is particularly crucial in environmentally sensitive semiconductor manufacturing.

Thus, the Wilson Optimus AMHS solution is not just an upgrade of "handling tools" but a reconstruction of the factory's logistics logic through digital means—it both improves space utilization, allowing every inch of cleanroom space to deliver maximum value, and ensures absolute safety during material flow and storage, ultimately providing solid logistics support for semiconductor fabs to reduce costs, increase efficiency, and improve quality.

*This article is authorized for reprint from the WeChat public account "Logistics Technology and Application" (ID: LMH_56).