GTRONTEC NTB: Smart Cache Hub Breaking the Efficiency Bottleneck of Semiconductor AMHS 'Last Meter'

In the article 'GTRONTEC Stocker: Covering Semiconductor Full Process Storage, Promoting Yield & Efficiency Dual Acceleration', we mentioned that to cover the full process storage needs of semiconductors, GTRONTEC has built a complete Stocker product matrix of 'core storage + supporting cache', including core products such as wafer cassette storage equipment (Normal Stocker), tower cross-floor storage equipment (Tower Stocker), reticle cassette storage equipment (Reticle Stocker), nitrogen purge storage equipment (N2 Purge Stocker), etc., and supporting equipment such as overhead cache equipment (OHB), near equipment cache equipment (NTB), etc.

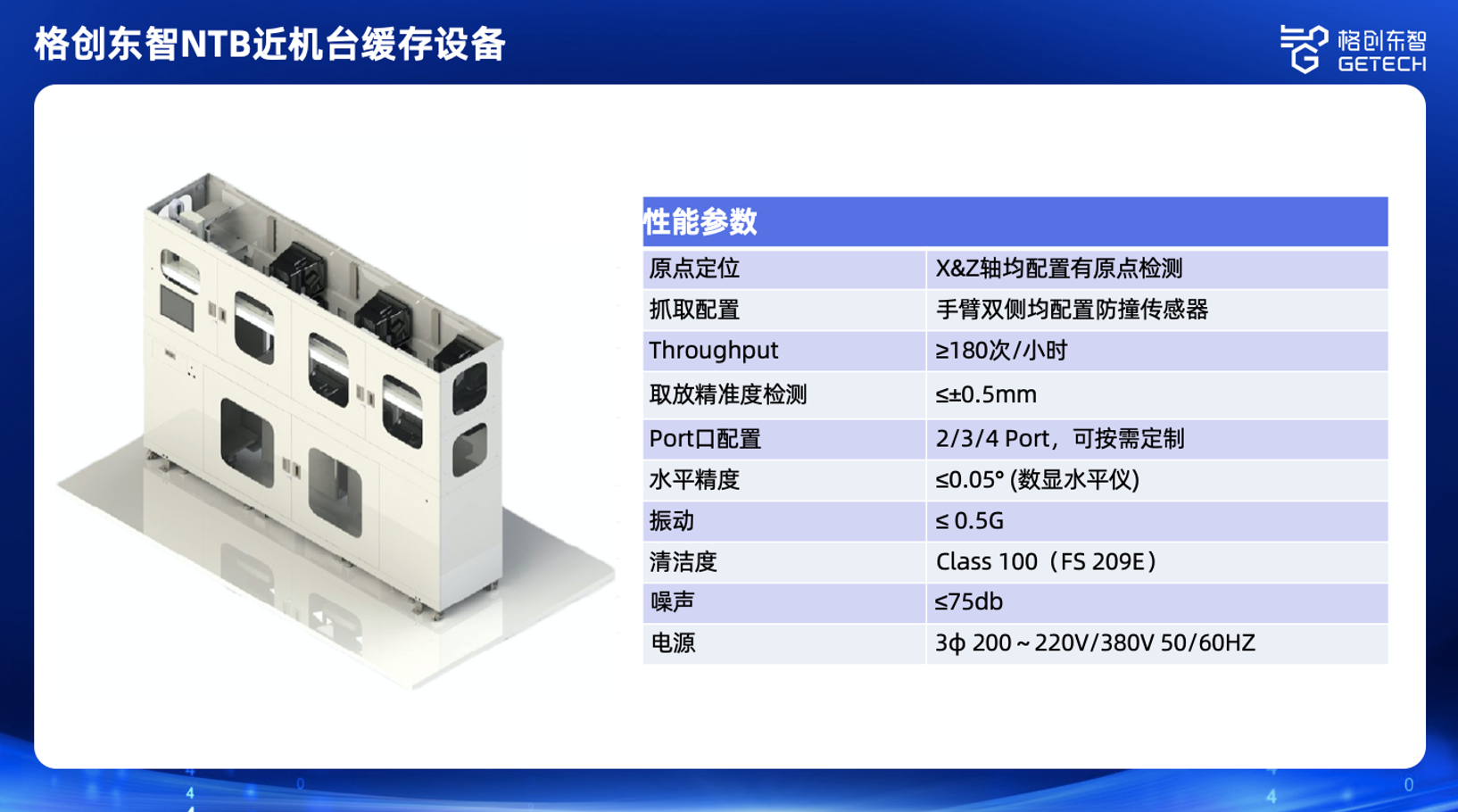

As a key role in the matrix focusing on the 'last meter near equipment', GTRONTEC NTB is an automated caching device customized for semiconductor production equipment (lithography, etching, deposition, etc.). Deployed next to the equipment, it fully utilizes vertical space to increase effective buffering, achieves efficient material transfer between 'OHT overhead hoist - production equipment', solves pain points in traditional logistics such as equipment waiting for materials, OHT congestion, and manual intervention contamination, thoroughly opening up the 'last meter' of semiconductor material automated flow.

AMHS 'Last Meter' Cache Hub, Three Features Make It Indispensable

In the semiconductor AMHS system, OHT overhead hoist handles 'cross-region long-distance transport', Stocker handles 'full-line centralized storage', and GTRONTEC NTB, with its three features of 'close distance, high frequency, fast switching', becomes the 'key link' connecting both to the equipment.

1. Close Distance: Extremely Compress Transfer Distance, Eliminate Delay

Flexible space deployment: Uses modular design, footprint only 1-2㎡, can be embedded in gaps of etching machine clusters, narrow channels beside testers, etc., without occupying core logistics pathways;

Second-level material handover: Distance to equipment Load Port only 1-3 meters, single Load/Unload time as fast as 10 seconds, much faster than OHT average response time, eliminating delays in logistics turnover, balancing rhythm differences between equipment.

2. High Frequency: Match Equipment Production Rhythm, Efficient Response

Continuous material change capability: Robotic arm uses lightweight design, with servo motor precise control, fastest single Load/Unload time ≤10 seconds, can complete at least 3 continuous Load/Unload tasks in 1 minute, perfectly adapting to high-frequency change needs of testers and sorters;

Local autonomous decision: Built with GTRONTEC self-developed control system, can directly receive equipment EAP commands, no need to rely on MCS system scheduling, avoiding response delays from network congestion.

3. Fast Switching: E84 One-Key Switch, Adapt to Multi-Scenario Flexible Production

E84 protocol is the core communication standard for equipment (EQ) and external devices (e.g., OHT/NTB) to achieve data interaction. In traditional mode, E84 switching has pain points like manual reconfiguration, long switch cycles, and error-proneness. GTRONTEC NTB innovatively develops E84 one-key quick switch function, no need to change hardware wiring, via NTB local touchscreen or remote MCS system, click 'Switch to OHT'/'Switch to NTB' to trigger, complete mode switch within 10 minutes, providing key support for flexible production lines.

Solve Equipment 'Waiting for Materials' Pain Point, Achieve Equipment Utilization & AMHS Efficiency Dual Improvement

GTRONTEC NTB is not just a simple 'temporary shelf', but through 'pre-stocking, automatic handover, buffer scheduling', brings value like equipment utilization improvement and AMHS efficiency optimization to semiconductor production lines.

Boosting Equipment Utilization: From "Machine Waiting for Material" to "Material Ready for Machine"

In traditional production models, equipment utilization typically sits at just 75%-80% due to factors like waiting for OHT delivery and Load Port full-stops. GTRONTEC NTB breaks this efficiency barrier through two key mechanisms:

Pre-buffering of WIP (Work-In-Progress): The MCS system issues transport tasks to the OHTC based on the equipment's production cycle. The OHTC then dispatches OHTs to deliver pending FOUPs to the NTB. This allows the equipment to immediately receive the next lot upon completing its current task, enhancing response time and eliminating "machine waiting for material."

Temporary Storage of Processed Materials: Completed wafer carriers can be temporarily stored in the NTB, awaiting batch transfer to the central Stocker by OHTs during idle periods. This prevents equipment downtime caused by full Load Ports.

Optimizing AMHS Efficiency: Balancing Load & Increasing Throughput

When all materials are delivered directly to tools by OHTs, it leads to frequent OHT dispatches and track congestion, especially during simultaneous material requests from multiple tools. GTRONTEC NTB balances the AMHS load through "buffer regulation":

Reducing OHT Non-Value-Added Travel: OHTs can deliver FOUPs for multiple tools to their respective NTBs in a single trip and later collect processed lots from NTBs for centralized return to the Stocker. This expands the coverage per task and significantly reduces the OHT empty travel rate.

Alleviating Track Congestion: Minimizes frequent stopping, starting, and queuing of OHTs in tool areas, thereby boosting overall AMHS throughput.

As one of the few domestic enterprises possessing comprehensive "AMHS Total Solution + Core Equipment Self-Development" capabilities, the value of GTRONTEC NTB extends beyond solving the singular pain point of "machine waiting for material." It acts as a critical link, seamlessly connecting the entire AMHS chain—from the efficient scheduling of OHTs and centralized storage in Stockers to the continuous operation of production tools—making it a key component in closing the automated logistics loop.

To date, GTRONTEC NTB has achieved cumulative shipments of 20+ units, with 95% deployed in leading domestic 12-inch advanced process fabs. Moving forward, GTRONTEC remains committed to its core principles of "technological self-sufficiency, deep scenario adaptation, and highly responsive service" to solidify and enhance its "AI + CIM + AMHS" total solution, empowering semiconductor fabs on their intelligent upgrade journey.