GT Insights Rewrites Semiconductor Manufacturing Decision Paradigms with AI Workflows [CIM Acceleration, AI Methods] No.2

In the semiconductor manufacturing field, data-driven precise decision-making is becoming the core competitiveness for improving yield and reducing costs. However, traditional data analysis systems often face three challenges, making it difficult to quickly extract the value of large amounts of industrial data.

- High access threshold: Relies on professional SQL writing or complex BI tool operations, blocking many business personnel from accessing data.

- Long analysis cycle: From data extraction, cleaning to modeling analysis, a complete yield root cause analysis often takes several days, causing severe decision lag.

- Difficult knowledge inheritance: The analysis experience and ideas of senior engineers are hard to accumulate and reuse, forming a dilemma of 'knowledge exists with the person, experience is lost when the person leaves'.

GTRONTEC's latest GT Insights product is designed to break this dilemma. As a conversational business intelligence analysis system based on natural language processing and large model technology, GT Insights is redefining data interaction methods in semiconductor factories. Unlike traditional BI tools, GT Insights supports users in directly obtaining required data analysis and visualization results through natural language dialogue, reducing the threshold and cycle of data analysis to an unprecedented level through AI workflows, realizing the vision of 'data democratization'.

1. Conversation as Analysis, Making Data Speak

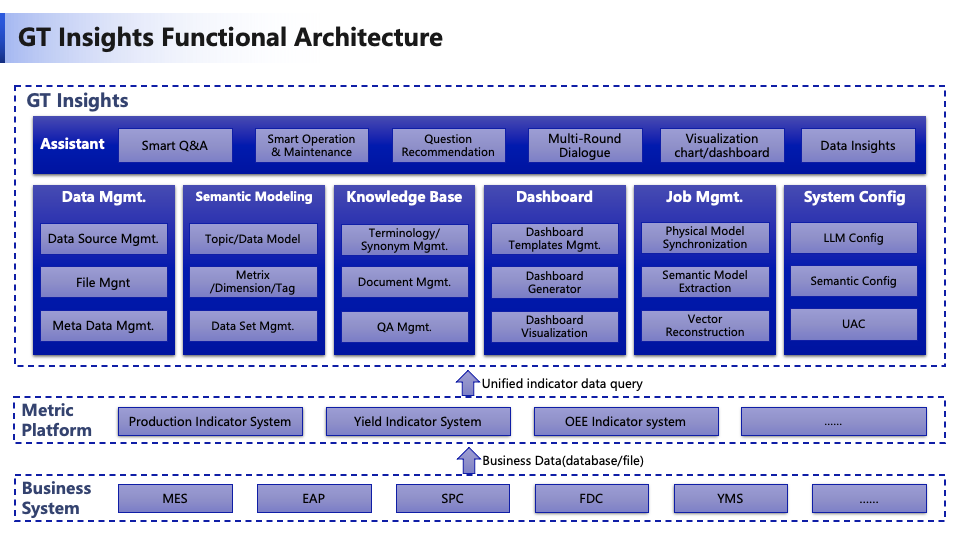

The core breakthrough of GT Insights lies in achieving a natural interaction mode of 'conversation as analysis'. Engineers only need to ask simple natural language questions, such as 'Show the yield trend of Product A in the third quarter', and the system can automatically understand the intent, completing the entire process from semantic parsing, SQL generation, data query to visualization presentation in the background, lowering the threshold for data analysis.

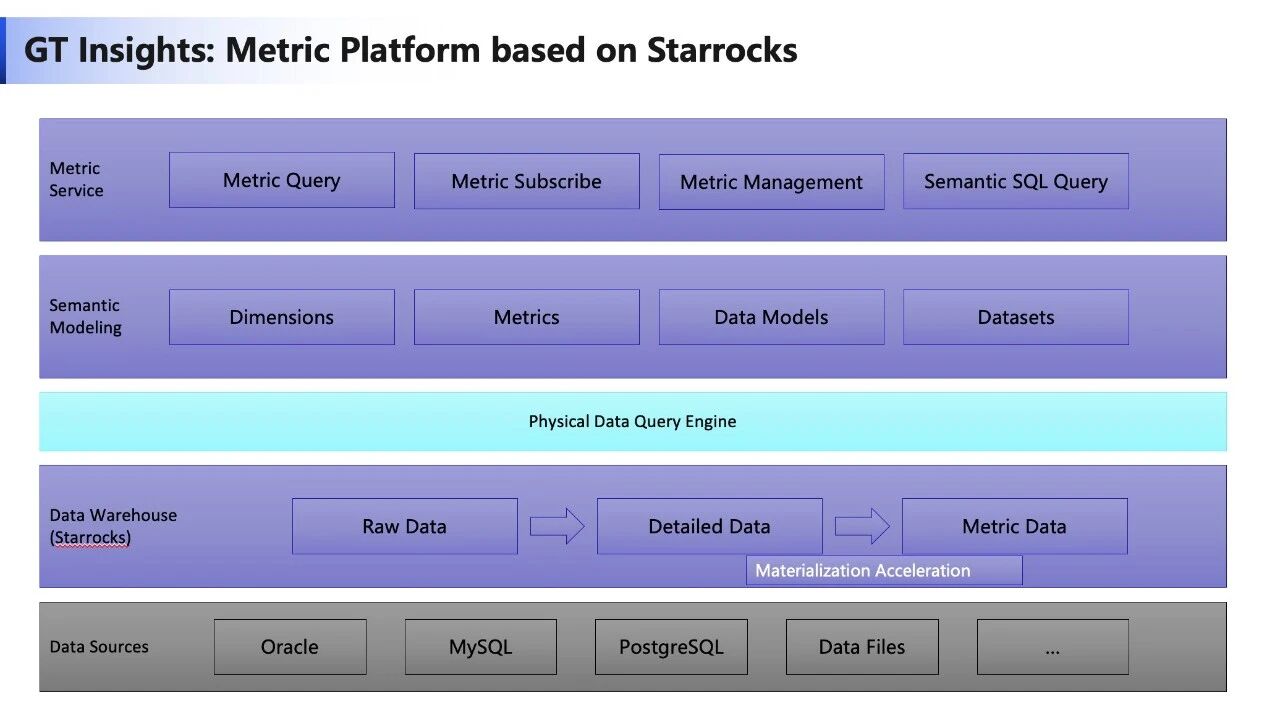

Its underlying technical architecture revolves around the semantic modeling layer, innovatively solving many challenges of LLMs directly processing physical databases in industrial scenarios. By building a semantic layer of business indicators and dimensions, the system transforms complex physical table structures into business-friendly data models, enabling LLMs to generate accurate semantic SQL, which is then converted into executable physical SQL through the semantic layer, achieving accurate understanding of business terms and generating reliable analysis results. This design not only significantly improves query accuracy but also makes the entire generation process verifiable and traceable, laying a solid foundation for subsequent intelligent analysis.

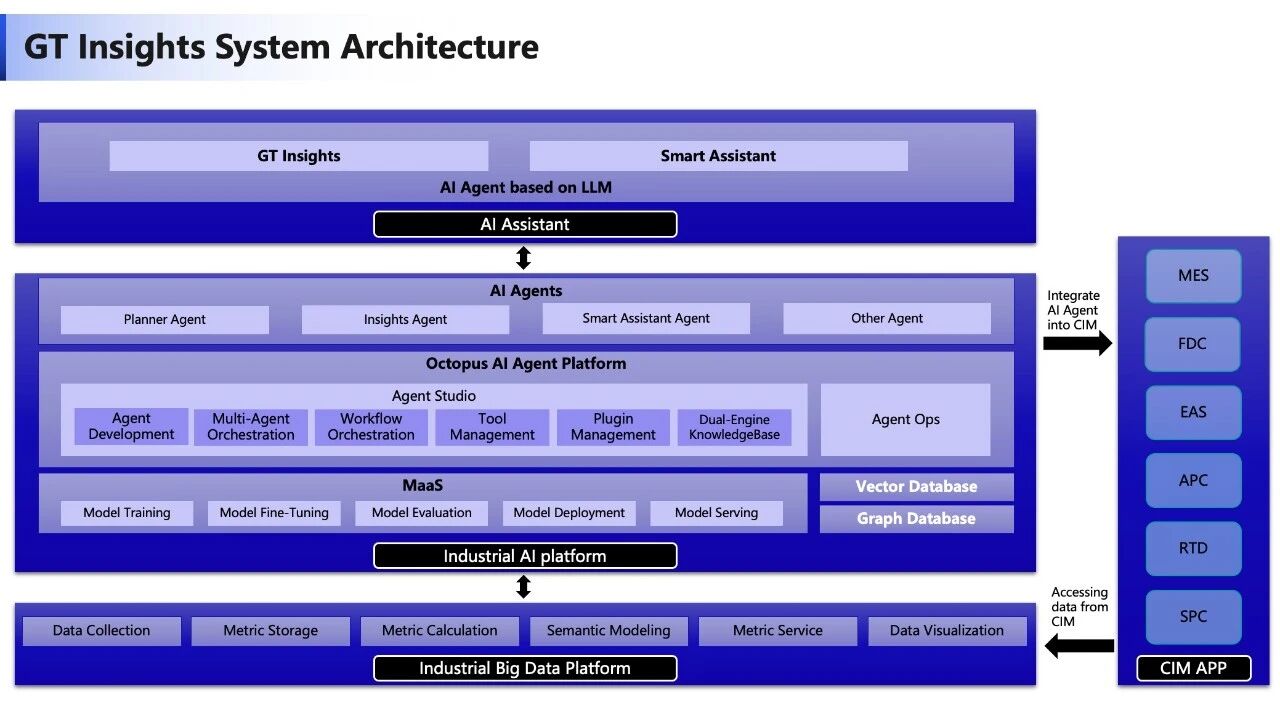

From a technical architecture perspective, GT Insights adopts a distributed deployment scheme, supports cluster expansion, ensuring high availability and stability of the system. Its core components include the semantic modeling layer, multi-agent framework, LLM integration layer, and StarRocks distributed data warehouse, together forming a complete industrial-grade intelligent analysis platform.

2. From 'Days' to 'Minutes', AI Workflow Reconstructs Yield Analysis Paradigm

Yield analysis is the most disruptive application scenario of GT Insights. In traditional models, a low yield root cause analysis often requires engineers to manually extract data across different systems, try various statistical methods for data collection, organization, and multi-dimensional cross-analysis, taking several days. GT Insights, through preset AI workflows, enables the system to automatically execute the complete analysis chain, compressing this process to the minute level.

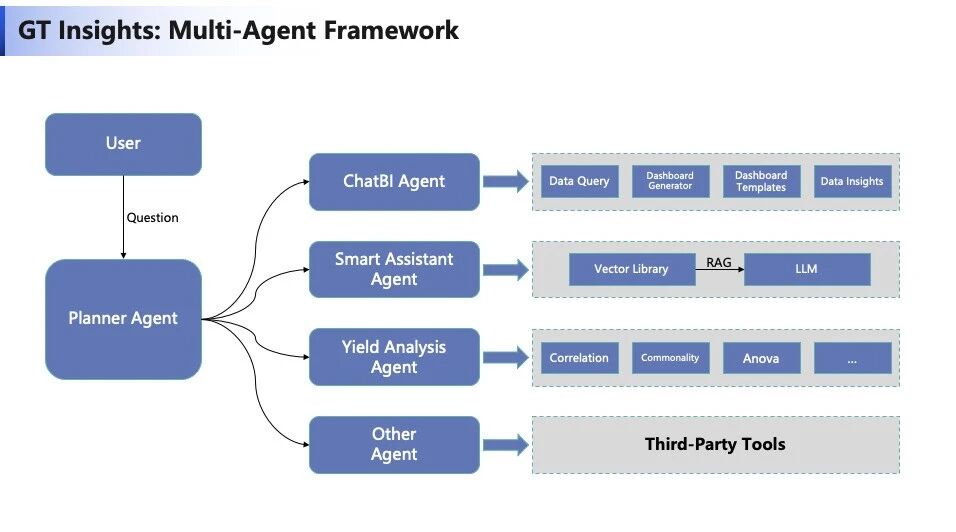

For example, when a user asks 'Analyze the reasons for low yield of Product A last week', the system automatically triggers a multi-step analysis process: first, intent recognition to lock the product and time range; then, execute Daily BIN analysis to locate abnormal BINs and time points; then, initiate HeatMap overlay analysis to identify defect distribution patterns; then, through Commonality analysis, trace back to suspicious machines; finally, generate a full-chain analysis report. The entire process requires no manual intervention, automatically generating a structured analysis report with clear direction and complete evidence chain including abnormal BINs and problem machines within minutes.

At the functional level, GT Insights demonstrates comprehensive data processing capabilities. From basic chart generation and multi-dimensional drill-down analysis to complex yield root cause localization and SPC statistical process control, the system can quickly respond through conversational interaction. Its unique Dashboard auto-generation function allows users to simply describe requirements in natural language, and the system intelligently arranges analysis charts to form a complete monitoring view.

3. Beyond Q&A, Agent Collaboration and Ecosystem Integration

The value of GT Insights goes beyond breakthroughs in single-point capabilities; it is an important component of GTRONTEC's CIM AI Foundation, developed based on GTRONTEC's Octopus AI Agent Platform 3.0, and can collaborate with intelligent 'digital employees' such as Planner Agent and Yield Analysis Agent through the AI Agent framework. It moves from passive response to active planning of analysis paths, calling third-party tools (e.g., SPC software, yield analysis plugins), forming closed-loop analysis decision-making capabilities.

At the system integration level, GT Insights offers 'driver' and 'co-driver' modes. It can be used as an independent analysis platform directly or embedded as a plugin into existing business systems like MES and YMS, allowing users to summon the AI assistant for auxiliary analysis while operating business interfaces, achieving a seamless experience of 'business operation as analysis'.

For semiconductor CIM systems, the introduction of GT Insights marks an important evolution from 'process automation' to 'intelligent decision-making'. Traditional CIM systems mainly focus on production process automation and data collection, while GT Insights endows these massive data with intelligent analysis capabilities, enabling manufacturing execution systems to truly possess intelligent features of self-perception, self-analysis, and self-decision.

Currently, GTRONTEC GT Insights has been successfully deployed in multiple semiconductor manufacturing enterprises, helping customers achieve significant results in yield improvement, equipment efficiency optimization, and production cycle shortening. For example, a semiconductor packaging and testing company originally faced issues like long yield analysis cycles, difficulty in accumulating expert experience, and data silos across multiple systems. By deploying GTRONTEC GT Insights, the company built full-chain analysis capabilities covering yield data, traceability information, and AOI images, significantly improving product yield and greatly reducing system operation costs and employee training costs.

With the continuous maturation of industrial large model technology, conversational BI represented by GT Insights is becoming an important direction for digital transformation in the semiconductor CIM field. GTRONTEC combines advanced AI technology with deep industry knowledge to provide a practical path for intelligent upgrading in the semiconductor industry, helping Chinese semiconductor manufacturing move towards higher efficiency, precision, and intelligence. In the future, GT Insights will continue to deepen specialized capabilities in specific semiconductor scenarios, expand solutions for more vertical industries, promote industrial intelligence from 'usable' to 'easy to use', and inject new momentum into the digital transformation of manufacturing.