GTRONTEC Attends China Smart Factory Summit, Dissects Core Points of Industrial AI Implementation

On October 21, the China Smart Factory Construction and Operation Summit was grandly held in Shanghai. GTRONTEC's Marketing Director Yang Li was invited to attend and delivered a keynote speech titled 'Industrial AI Breakthrough: Accelerating New Quality Development with Practical Implementation', discussing the future path of deep integration of artificial intelligence and manufacturing with authoritative experts and entrepreneurs from China Academy of Information and Communications Technology, Superfusion, Bosch Automotive, etc. in the smart manufacturing field. As a representative of a leading enterprise in the industrial intelligence field, Yang Li systematically elaborated on GTRONTEC's implementation path to promote high-quality development of manufacturing through industrial AI, and shared implementation practices in TCL and multiple leading manufacturing enterprises.

Yang Li first proposed that industrial AI is moving from single-point technology applications to comprehensive intelligent application stages, and is penetrating core manufacturing links at an unexpected speed, quickly forming breakthrough points in key scenarios of manufacturing. This insight echoes the previous strategic judgment of GTRONTEC CEO He Jun that AI+ is rapidly intervening in the core of manufacturing enterprise transformation at an ultra-fast speed. The capability foundation accumulated by leading manufacturing enterprises through digital transformation enables AI technology to quickly integrate into core manufacturing links, and this trend is particularly evident in advanced manufacturing fields such as China's semiconductor and new energy industries.

When discussing the methodology for industrial AI implementation, Yang Li highlighted GTRONTEC's ABCDE framework. This framework covers five key elements: algorithm, big data, computing power, domain knowledge, and intelligent equipment. Yang Li emphasized that for manufacturing to use AI well, domain knowledge is the most critical entry ticket and benchmark. Introducing professional domain knowledge can significantly improve the stability and accuracy performance of large models. This view reveals the essential difference between industrial AI and general AI.

"A batch of enterprises are rapidly applying AI technology to various business scenarios. This multi-scenario, deep-level intelligent transformation is becoming a new characteristic of Chinese manufacturing." Yang Li further stated. This view is also confirmed in GTRONTEC's recent projects. For example, in a traditional enterprise, driven personally by the client's chairman, the enterprise launched four AI projects within half a year, from supply chain to equipment management, demonstrating the determination and speed of traditional industries embracing intelligence. GTRONTEC believes that a batch of Chinese enterprises can comprehensively use artificial intelligence in a very short time and push it to various scenarios.

In terms of scenario value, Yang Li stated that AI is shifting from 'tool empowerment' to 'decision assistance', which is the essential difference between the AI era and the digital era. The digital era focuses on how to make people do things faster and more correctly, while the AI era focuses on teaching people what to do and make decisions more correctly and efficiently. This shift from 'how to do' to 'what to do' is the revolutionary change brought by industrial AI. In GTRONTEC's view, the core value of AI investment in advanced manufacturing is not cost savings, but the improvement of precision. For example, in the practice of serving TCL Huaxing, a leader in the semiconductor display industry, the company achieved deep empowerment of industrial AI based on intelligent application scenarios of five major digital platforms: R&D, supply chain, product, sales, and ERP. In the quality management scenario, through the AI ADC industrial visual inspection system, defects are automatically detected, classified, and handled, with defect detection accuracy increased to 95%, saving about 50 million yuan annually.

As an industrial intelligence leader strategically incubated by TCL, GTRONTEC has consistently addressed smart manufacturing and industrial AI implementation challenges through its three strategic pillars: "AI + Industrial Software + Intelligent Equipment." With focused industry specialization, GTRONTEC has positioned semiconductors as its strategic core, leveraging integrated "AI + CIM + AMHS" solutions to help the semiconductor industry achieve "high-cycle, zero-defect" production targets.

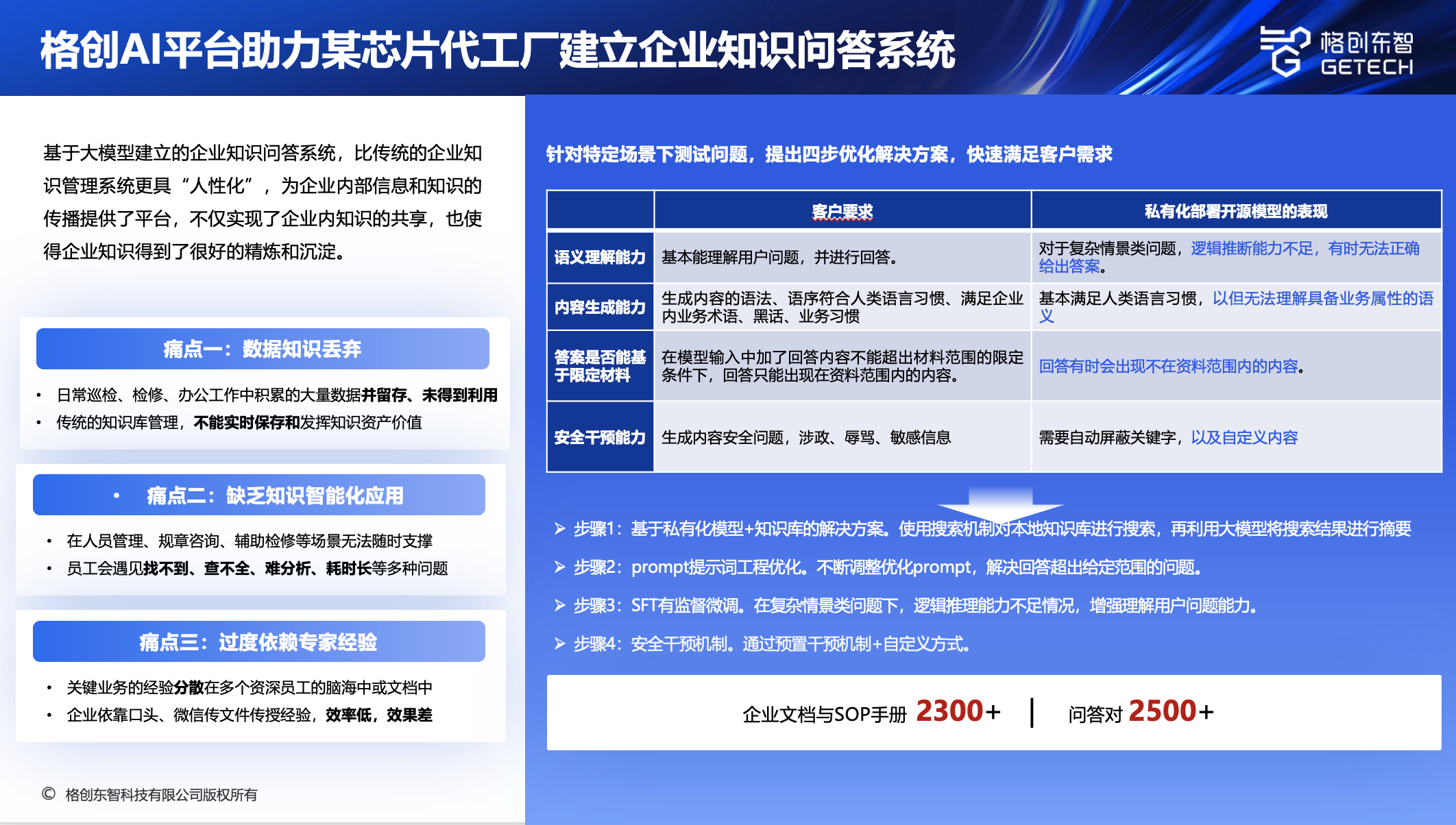

Over its seven-year journey, while empowering TCL's comprehensive digital transformation, GTRONTEC's solutions have been rapidly replicated across multiple sectors. Yang Li cited examples: an enterprise-level knowledge Q&A system built for a chip foundry refined, accumulated, and preserved manufacturing know-how; in new energy batteries, AI prediction models enabled precise cell quality assessment, reducing critical customer complaints by 80%; for photovoltaic wafer yield management, their self-developed yield monitoring platform achieved real-time analysis, saving monthly labor costs by 50,000 to 100,000 RMB.

Yang Li stated that in the future, GTRONTEC will focus on investing in three core capabilities: industrial data value realization, industrial Agent platform upgrade, and factory scenario application innovation, revealing GTRONTEC's development goal of focusing on 'how to help customers realize the value of industrial data well'. The sharing at this summit not only demonstrated GTRONTEC's technical depth and scenario breadth in the industrial AI field, but also highlighted the mature trend of Chinese industrial intelligence moving from 'concept verification' to 'value implementation'.

With the restructuring of the global manufacturing landscape, industrial AI is becoming an important chip for Chinese manufacturing enterprises to participate in international competition. GTRONTEC will continue to deep cultivation in industrial AI implementation core scenarios, through replicable and promotable industrial intelligent solutions, help Chinese advanced manufacturing gain an advantage in the AI wave.